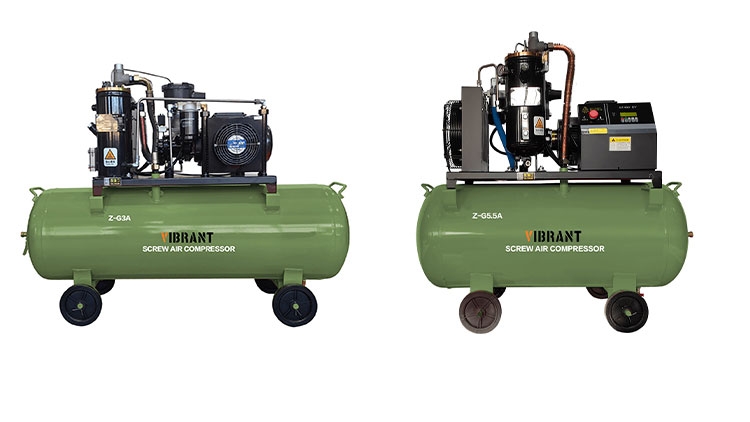

Fixed Speed Rotary Screw Air Compressors: Dependable Control over Power

Air compressors of rotary screw type are used in manufacturing, automotive, and metalworking industries which need precise, constant airflow as they perform tasks incessantly. Fixed Speed Rotary Screw Air Compressor provide efficiency owing to low operational fuel consumption coupled with cost-effective maintenance and simpler construction which lowers the overall upkeep cost. Moreover, the ease of construction associated with rotary components enhances durability alongside the ease with which these compressors are provided. Alongside discussing the diverse sectors that fixed speed compressors help named, attention will be paid to their advantages.

What advantages of using Fixed Speed Rotary Screw Air Compressor?

Uninterrupted and Dependable Performance

These Screw Air Compressors, unlike others, stand apart due to their unique calm mode of operation. Constant speed provides pressurized or non-pressurized continuous airflow, which comes in handy for industries such as automotive, metalworking, and manufacturing, which have close relationships with Air Compressor Systems. Air supply must be provided fluidly without any interruptions to prevent halting the processes.

Increased productivity in your businesses - rotary screw air compressors may become overloaded and will maintain optimal airflow performance with no interruption for long periods.

Routine Maintenance and Operating Expenses

The major advantage of screw compressors is that servicing cost is much lower than other types of compressors. This is because most screw-type rotary compressors require limited servicing due to having few vital components and moving parts. Unlike most other air compressors, these design features reduce the possibility of malfunctions, breakdowns, and an assortment of expensive repairs. Because operational costs associated with fixed-speed air compressors are lower, servicing air compressors is ideal for businesses seeking to lower maintenance costs.

Ease of Use

Because of the distinct form of the rotary screw compressor, servicing does not require a lot of effort. One training session is enough for both instructions on control systems and a fundamental overview of circuits, as long as they reach basic competency and verify that crucial processes in system execution are carried out effectively. These compressor types are best used in industries, and indeed, these compressors serve the purpose.

Space Saving Advantages

These benefits of users with no increase in operational bounds loads minimize the limit, furthermore, there is no lower operational bounds. The operating range does not suffer, and with these advantages, users enjoy uninterrupted, constant frequency operation. Maintenance footprint is reduced with this dual structure, which leads to space savings. Reducing footprints in operation and installation areas has been achieved because Auxiliary equipment is not needed.

Applications of Fixed Speed Rotary Screw Air Compressors

The sectors listed below appear to utilize Fixed Speed Rotary Screw Air Compressor:

Manufacturing: To provide the required compressed air supply for the operation of pneumatic tools and other machines within the manufacturing.

Automotive: Providing air for operating spray painting and other pneumatic functions on the assembly line.

Metalworking: To operate tools and machines that require an uninterrupted compressed air supply for cutting and de-molding.

Verified and claimed reputation of fixed rotary compressors by all industries is based primarily on the reliability, life span, cost-incurring value, and consistent air pressure.

Key components of an Air compressor

Moving parts of Rotary screw air compressors with fixed speed, here are some key components as Air compressor works only without additional components i.e. its electricity supply.

- Each round screw compressor has two rotors, which constitute one of the two major parts of the compressor. Both rotors spin and compress air simultaneously. The rotors are configured in such a manner that they rotate into each other, compressing air into progressively smaller cavities.

- The rotary motion of the compressor and the speed of the rotors are driven by the motor, which in turn rotates the screw.

- The air intake valve enables air to flow into the compressor. Thus, this component governs the flow of air into the compressor.

- Proper airflow must be maintained within the machine. An inadequate airflow for a fixed speed machine will cause the unit to run sluggish, with overheating coolant flow

- The valve controls the outlet of the trapped compressed air in the system, therefore, it is called a discharge valve.

Operational and Technical Metrics of Fixed Speed Rotary Screw Air Compressors

Like other fixed speed rotary screw air compressors, performance metrics have to be evaluated. These metrics incorporate supplies and fixed speed rotary air compressors' performance KPIs, which most often include the following:

Horse Power (HP)/Kilowatt (kW)

In terms of HP, air compressors have a wide range available. This figure captures the overall power output of a compressor. For small businesses, a 10 HP Fixed Speed Rotary Screw Compressor would be sufficient. Larger systems that serve high-volume applications require as much as 50 HP to maintain steady pressure.

CFM (Cubic Feet per Minute)/LPM (Liters per Minute)

CFM is the metric used to determine the measure of air compressed by a rotary screw compressor. For some industrial processes, there is a need for compressed air with a higher CFM rating; this is important. An example of a fixed-speed compressor would be one that can deliver 250 CFM, which would serve large-scale industrial and manufacturing operations.

PSI (Pounds per Square Inch) / Bar

A compressor’s output is measured by the air pressure the assigned work can yield, which can be represented by PSI or bar.

An older product of rotary screw compressors will perform worse than a VSD unit. These rotary compressors are less productive because their fixed speed is quite inefficient. In the industry, these types of motors have fixed speeds with minimal cycling, which leads to no energy waste and maximum efficiency.

Selection Criteria for Purchasing a Fixed Speed Rotary Screw Air Compressor

Estimate the Volume of Air Needed

Before purchasing rotary screw compressors, analyze all possible options for Meeting a Spiral compressors air procurement needs, which, for instance, is the case with some smaller companies which require a single-stage screw compressor with low power rating. Alternatively, two-mighty operations would require a two-stage screw compressor to service their greater needs and carry additional weight.

Ensure the Efficiency of the Selected Class

The basic duty of users is to acquire an appropriate power rating for their business.

Maintenance for Low Band Consumers or Nonprofit Operators

The same compressed air supply system will be wasted on the unit that has higher operating units, but those with lower operating units will not perform well on the supply side of compressed air.

Analyze the Application

Additionally, light and moderate industries will be a belt-driven screw compressor, while more critical applications will need a gear-driven screw compressor.

Maintenance Requirements

Assess the maintenance concerning the compressor. In this case, the fixed speed models are simpler to maintain scheduled maintenance; however, these must maintain on air filter, oil, and others periodically.

Conclusion

For businesses requiring rotary screw air compressors depend on the reliable and continuity in the availability of compressed air integers the rotary screw air compressor. It is dependably durable, except for its outflow while gaseous and low-melting within supporting the manufacturing, automotive, woodworking, and metal working industries. Understanding the most essential features and specifications of Fixed Speed Rotary Screw Air Compressor enable optimal efficient decisions. VIBRANT stands ready to assist for additional rotary screw air compressors and other industrial solutions.