The Hidden Influence Fueling Modern Industry

Ever paid attention to the sharp hissing sound that comes from a power tool or a tire pump? That is an example of compressed air, one of the industry’s unsung heroes. Its importance is seen from manufacturing to medicine, as it aids in powering processes that impact our lives. So, what is compressed air, and why is it so important? Its constituents, how it works, its components, types of compressors, compressors’ range of use, and its versatility as an energy source.

Compressed Air Definition

Compressed air is simply air that has been squeezed into a smaller space, increasing its pressure. Technically, it is atmospheric air reduced in volume through compression. This high-pressure air can be released in a controlled manner to perform work, for instance, powering a drill, lifting heavy loads, or even spraying paint.

The science behind it is very simple. According to Boyle’s Law, if temperature is constant, a gas’s volume reduction causes an increase in its pressure, and that works for everything from pneumatic tools to large industrial machinery.

Air Compression Explained: The Basic Working Principle

Let’s simplify it.

1. Intake: The air compressor inhales the surrounding air.

2. Compression: The air is pressed using pistons, screws, or impellers, increasing its pressure.

3. Storage: The air is stored in a receiver tank.

4. Release: The air is accessed through valves and pipelines to power different applications.

While the concept may seem straightforward, there is a great deal of engineering work alongside automation and control systems tuned to maintain optimal PSI and CFM for airflow.

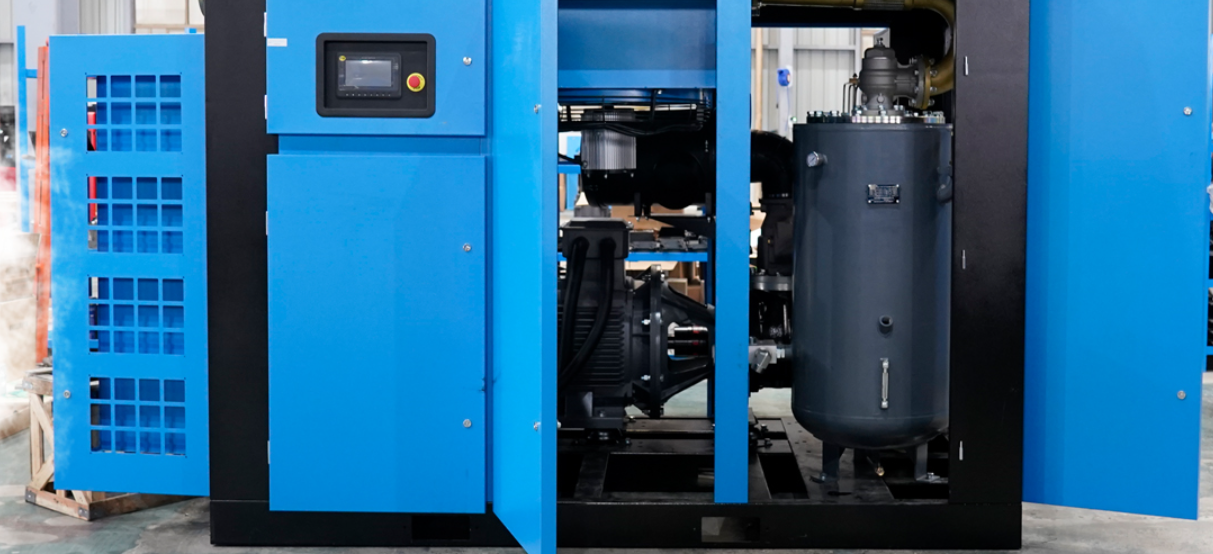

Components of a Compressed Air System

A compressed air system contains more than a compressor. It also includes:

• Compressed air filters

• Advanced air moisturizing systems, such as the air dryer

• Compressed rotary screw or centrifugal piston air compressors

• Air receiver tank, which stores the compressed air

• Pressure regulators and valves

• Piping network

• Elimination of oil, dust, and particle filters

These systems make sure that a clean, dry, and consistent compressed gas is provided. This is extremely critical in the pharmaceutical, food, and automotive industries, which are sensitive in nature.

Different Air Compressors: Which One to Select

There are different air compressor types based on your specific needs. Here’s a brief overview:

1. Positive Displacement Compressors

These types compress air by decreasing the size of an enclosed space.

• Reciprocating Compressor: Uses pistons and is best for intermittent use.

• Rotary Screw Compressor: Popular in industries due to its continuous operational capacity.

• Scroll Compressor: Used in the medical field due to being quiet and oil-free.

2. Dynamic Compressors

These elevate pressure by increasing the velocity of a given air volume.

• Centrifugal Compressor: Large industrial systems use this due to the high flow and oil-free nature.

3. Oil-Free vs. Oil-Lubricated

• Oil-Free Compressors: Suitable for clean environments such as food and pharmaceuticals.

• Oil-Lubricated Compressors: While these have greater operational efficiency and lifespan, they require more upkeep.

How Does Compressed Air Work in Real Life?

Beyond electricity, water, and gas, compressed air is referred to as the fourth utility. It exists everywhere and serves an essential function. Here’s how it powers various sectors:

Industrial Compressed Air Uses

• Operating pneumatic tools like drills, hammers, and grinders

• Powering robotic arms and assembly lines

• Running conveyors, clamps, and actuators

Automotive Industry

• Paint spraying for smooth, even coats

• Tire inflation and diagnostics

• Pneumatic lifts and air brakes

Construction

• Jackhammers, compactors, and concrete vibrators

• Nail guns and other framing tools

Medical & Pharmaceutical

• Oxygen delivery systems

• Dental air tools

• Capsule filling and sorting

Benefits of Compressed Air

Why do so many industries rely on compressed air? Let’s look at the top advantages of compressed air:

Versatile Energy Source

It can power a wide variety of tools and machines.

Clean and Safe

Especially with oil-free systems, it’s ideal for cleanroom environments.

Low Energy Usage

More efficient than mechanical systems, they incur less energy loss in continuous operations.

Versatile and Mobile

Compressors can be scaled down to fit DIY projects or scaled up to suit industrial requirements.

Optimized Energy Usage

Reduced energy usage and optimized performance can be achieved with modern air audit systems with variable speed drives.

Air Pressure and Quality Standards

Compressed air systems have to comply with the industry standards for safety and efficiency.

PSI and CFM

• PSI measures pressure. Greater PSI indicates increased force.

• CFM measures the air volume delivered.

ISO 8573-1

This standard classifies the purity of compressed air, which is vital for sensitive industries like electronics and medicine.

Air Treatment Matters

• Dryers prevent rust and corrosion by removing moisture.

• Oil filters and microbial filters remove particulates, oil, and microbes.

• Air audits are conducted periodically to maintain quality and efficiency.

Compressed Air in Pneumatic Systems

Pneumatic systems transform compressed air into pneumatic energy, which is a type of mechanical energy. Such systems include:

• Cylinders: Provide linear motion

• Valves: Control the direction and rate of airflow

• Actuators: Transform pressure into movement

The great thing about pneumatics is their ease of use, safety, low cost, and suitability for repetitive tasks.

Streamline Performance of Your Compressed Air System

Along with improving performance and the life span of your equipment, optimizing your compressed air system greatly enhances energy-saving measures. Systems that are well-designed and maintained provide long-term savings and significantly minimize environmental impact.

- Start with the installation of variable speed compressors that adjust output to match demand, eliminating energy consumption during low-use periods. Pair that with air leak detection sensors that tackle one of the biggest energy wasters in compressed air systems—air leaks. Even the smallest of leaks, if left unchecked, can add up to thousands of dollars annually.

- Air receivers help reduce compressor cycling, ensure smoother operation, and less wear by storing compressed air. Preventive maintenance is just as important; system filter changes, lubrication, and inspections on a set schedule help avoid expensive system failures and ensure consistent operation.

- Evaluate system efficiency, identify bottlenecks, and uncover hidden losses through periodic compressed air audits. These audits gather valuable data to help fine-tune your setup and provide justification for upgrades while optimizing system performance.

Conclusion

What is compressed air? It is more than just air stored in a tank. It is a versatile energy source with compressed air systems that provide reliability and support in critical functions for industries. Be it the tools at a car workshop or the machines in a snack packaging plant, compressed air systems are crucial in maintaining the functions of almost every industry.

Optimizing the use of compressed air, its basic components, and applications helps in saving energy and reducing costs, greatly improving productivity for factory managers and even for DIY enthusiasts working at home, sharpening their toolset.