Overview of the Air Compressor

The air compressor sits at the core of many factories and shops, quietly powering everything around it. When that workhorse starts acting up, productivity tumbles, and the bottom line suffers. One problem that often flies under the radar is a clogged oil-water separator. Although small, this part keeps the air clean and the system healthy, yet it can easily be clogged with debris.

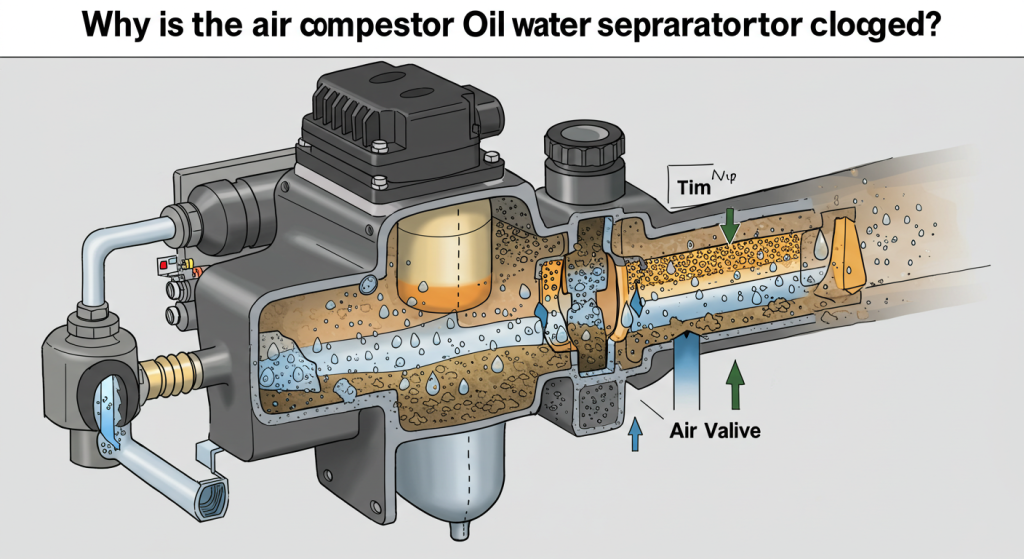

What is an Oil-Water Separator in an Air Compressor?

An oil-water separator removes oil from the condensate that forms inside the compressor. By doing so, it lets the leftover water leave the system safely and keeps harmful oil from leaking into the environment or corroding costly downstream gear. Rotary-screw compressors usually house the separator, which catches emulsified oils, sludge, and moisture before the compressed air reaches tools and equipment.

A blocked oil-water separator isn’t just an annoyance that can bring your air-compressor system to a halt. Whether you notice pressure drops, oily discharge, or unwanted water in the lines, knowing why the separator clogs is the first step toward a fix.

1. Lack of Regular Maintenance

This reason tops the list. Dust, dirt, sludge, and oil residue pile up over time. If the separator’s filter isn’t changed when due, it soaks up solids until it stops working. Blocked scavenger lines or clogged condensate drains only add to the problem.

2. Poor Quality Compressor Oil

Not all lubricants are the same. Low-grade oil breaks down quickly and leaves behind sticky varnish. Contaminants in cheap blends, such as excessive additives and water, go straight to the separator.

– Bargain compressor oils oxidize faster under heat.

– They break down and form sludge that gum up the separator media.

– This causes quick filter clogging and can kill the separator.

3. Overloaded with Moisture

Too much water is a big problem.

– Without a dryer, moisture builds up inside the air system.

– Water and oil mix, forming a thick emulsion that is hard to split.

– As the filter works overtime, the separator blocks and floods.

4. Improper Drain Function

If your drain isn’t working, the system is already in trouble.

– Float drains jam with sludge, debris, or lime scale.

– Timed or electronic models can fail if staff forget to service them.

– The result? Condensate pools in the separator and overflows.

5. Filter Media Degradation

Everything wears down eventually, and that includes filters.

– After many hours, a separator’s filter media starts to crumble.

– Heat, chemical mist, and steady pressure speed up the fade.

– Resistance climbs, pressure drops, and the air quality turns sour.

Signs Your Oil-Water Separator is Clogged

Watch for these warning lights:

1. Oil in Compressed Air

Dirty air is the first alarm. It can cause:

– Broken tools

– Poor paintwork

– Unresponsive valves

2. Excess Water in Air Lines

When separators quit, moisture skips past and rusts everything down the line.

3. Visible Oily Discharge

Oil in the condensate drain shows the separator is either blocked or failing.

4. Pressure Drop

A clogged element chokes airflow. Energy use rises, and production slows.

5. Separator Overflow

Water spilling from the unit means it can no longer hold, and the system is full.

How to Fix a Clogged Oil-Water Separator?

Step 1: Shut Down and Bleed Pressure

Don’t touch a pressured system. Switch off the compressor, bleed air, and lock valves.

Step 2: Examine Drains and Hoses

Look at:

– Float drain valves

– Steam traps, if any

– All drain pipes for sludge

Clean, clear, or swap worn parts.

Step 3: Remove and Clean the Separator

If safe to do so:

– Unbolt the casing.

– Wipe walls and baffles.

– Fit OEM filters.

Step 4: Inspect the Scavenging Line

This pipe sends oil back to the compressor. Block it, and the separator overflows.

Blow through it or soak it in the solvent.

Step 5: Final Check Before Restart

Start the system and:

– Scan for drips

– Watch the water quality

– Confirm airflow and pressure

How to Prevent Separator Clogging Long-Term?

Prevention saves money and downtime:

1. Stick to the Maintenance Schedule

– Change filters every 3 to 6 months.

– Inspect the unit monthly.

– Record pressure numbers.

2. Use the Right Compressor Oil

– Follow the OEM’s oil specs.

– Never mix oil brands.

– For food plants, use food-safe grades.

3. Keep Moisture Under Control

Fit air dryers wherever humidity is a problem.

Place coalescing filters before the separator.

Check dew points on a routine basis.

4. Empty Drains on Schedule

Sludge builds up fast, turning valves into blockages. Look at them each week.

5. Watch Pressure and Flow

A sharp pressure dip usually means something is stuck.

Install differential gauges across filters and separators.

Compressor Oil-Water Separator Tips

Why is the air compressor oil-water separator clogged? Removing moisture and oil from compressed air keeps machines running and protects downstream tools. When an oil-water separator is neglected, air quality drops, pressure creeps up, and oil winds up where it shouldn’t. Stay ahead of trouble with these simple habits:

- Daily Tasks

Drain oily condensate if the system doesn’t do it automatically. That small step stops flooding and keeps sludge from forming.

- Weekly Checks

Look at the float drain. If it sticks or leaks, repair it fast, as clogged floats waste money and prompt bigger failures.

- After 2000-4000 Hours

Swap in a new separator cartridge. Old elements choke airflow and let oil slip through.

Monthly Maintenance

Test the air for excess moisture or oil. Persistent high readings suggest a faulty separator or dryer upstream.

- Quick Post-Service Check

After any big repair, take a moment to look for stray oil drifting back into the system. Spotting that issue early shows the oil separator and scavenging pipes are doing their job.

Conclusion

Why is the air compressor oil-water separator clogged? One blocked oil-water separator may feel trivial, yet it can seize the whole air circuit. Pressure loss, ruined tools, and messy legal headaches over waste puddles are risks you don’t want. Stay ahead: pick the right oil, keep filters clean, watch drains, and choose solid parts. For deeper compressor tips, explore Vibmac- your go-to source for steady industrial upkeep. Visit VIBRANT.