Introduction to Rotary Compressor Vs. Scroll Compressor

Choosing the best compressor for an HVAC unit or a refrigerator can feel overwhelming, yet knowing the basic contrasts between rotary compressor vs scroll compressor designs can spare you time, expense, and frustration. This brief overview explains both styles in straightforward terms, lists advantages and drawbacks, notes common applications, and remains friendly to search engines. Whether you are an engineer, facilities manager, or homeowner upgrading an air conditioner, keeping these points in mind will help you confidently decide.

What is a Rotary Compressor?

A rotary compressor is a positive-displacement device that relies on a rotating element – often a vane, screw, or piston – to trap and squeeze refrigerant as it travels through the machine.

Working Principle

Because the spinning part isolates gas in a defined chamber, reduces its volume, and moves it forward, the process delivers high capacity, smooth operation, and a small refrigerant charge.

What is a Scroll Compressor?

A scroll compressor contains two spiral plates that nest together. One plate remains fixed while the other orbits gently around it, forming discrete pockets of gas that shrink with each revolution until the refrigerant exits under high pressure.

Working Principle

Inside a scroll compressor, refrigerant first enters at the outer edge; as the orbiting scroll turns, it nudges the gas along a spiral path toward the center, steadily raising the pressure. The now-compressed gas flows out through the center outlet, supplying high-pressure fluid to the next stage of the refrigeration system.

Rotary Compressor Vs. Scroll Compressor: Key Differences

Selecting the right compressor, whether rotary or scroll, requires knowing how each type performs in day-to-day operation. The following table highlights their main contrasts.

- Efficiency

Scroll models usually operate at higher efficiency, delivering a steady cooling output while drawing less power; well-built rotary units, however, still fall in the moderate-to-high efficiency range.

- Noise Level

Because rotary designs contain rapidly spinning vanes and bearings, they tend to generate more noise; in contrast, the smoother motion of a scroll compressor makes it much quieter, ideal for homes and noise-sensitive offices.

- Cost

On the purchase front, rotary compressors are cheaper, so they appeal to tight budgets; scroll units carry a higher sticker price but gradually offset that cost with lower electricity bills.

- Maintenance

Scroll compressors have relatively few moving parts, so they demand little routine care; rotary designs, by comparison, need regular checks and periodic lubrication to limit wear.

- Lifespan

The sturdy build of most scroll compressors often translates into a longer service life, while rotary units subjected to heavy loads may exhibit signs of fatigue sooner.

- Applications

Rotary compressors work well in domestic air conditioners and compact chillers, where space is tight. Scroll compressors, by contrast, serve HVAC rigs, heat pumps, and bigger commercial equipment.

- Size and Operation

Rotary units are lightweight, usually run continuously, and handle only modest heat loads. Scroll machines are heftier but cycle smoothly, producing less vibration and lower noise.

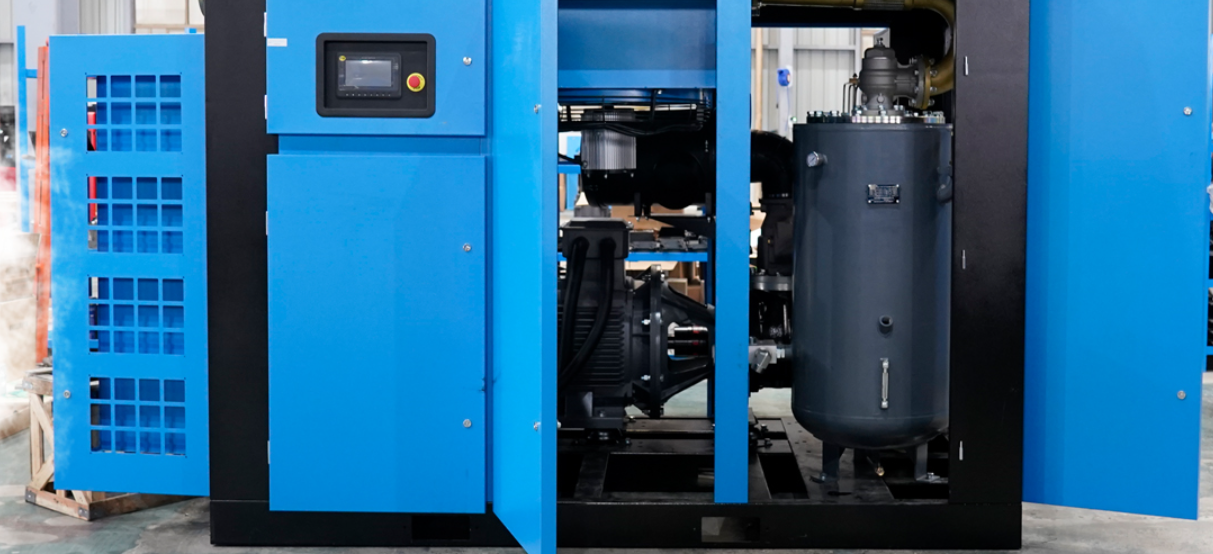

Rotary Screw Air Compressor – Best Choice for Industrial Applications

- In heavy factories, the Vibrant Rotary Screw Air Compressor leads the pack with sheer power and dependability. Built for tough shifts, it delivers a steady airflow that keeps assembly lines, auto shops, and high-output plants on schedule. Its twin-screw rotors operate quietly, trim electricity costs, and reduce wear over time.

- Pair that output with Rotary Screw Air Compressor Oil JX-50APML, crafted for severe-duty applications. This premium lubricant cuts friction, defends against heat and debris, and extends service life during long, intense cycles.

- Highly rated for thermal and oxidative stability, JX-50APML keeps the compressor clean, cool, and running smoothly even after marathon shifts. Whether the job is round-the-clock or follows an abrupt start-stop pattern, a Vibrant rotary screw unit paired with JX-50APML oil provides maximum uptime, lower maintenance, and steady output. For operations that cannot afford downtime, it remains the clear first choice.

- Because a scroll compressor moves gas in a constant, smooth arc, it usually draws a bit less electricity in HVAC work than other options. Most twin-rotary models are good performers as well, but they must turn at higher RPMs to reach the same output, which can push power use higher.

- Noise is always a worry in homes and offices. With fewer moving parts and no valves, scroll units hum along in a whisper. Rotary designs, by contrast, can generate more mechanical chatter.

- On the budget sheet, rotary compressors win the upfront race, explaining their presence in cost-conscious AC and mini-split systems. Scroll units, though pricier at checkout, pay back the gap over time with remarkable durability and efficiency.

Maintenance Requirements

Rotary compressors require regular oil top-ups and frequent inspections because their high-speed rotors generate heat and friction. Scroll units, in contrast, have fewer moving parts and sealed lubrication, so day-to-day upkeep is minimal.

Lifespan Comparison

- Scroll compressors generally outlast rotary models since their design keeps runaway friction and wear to a minimum.

- Rotary units can deteriorate more quickly if run at full load for long stretches.

- Rotary compressor life: about seven to ten years

- Scroll compressor life: about twelve to fifteen years

- Which type works best depends on matching its strengths with the job’s needs.

- Both designs climb the performance ladder in nearly any setting.

Rotary Compressor Strengths

Rotary units cost less upfront, a bonus for budget-conscious operations. Their small size lets technicians squeeze them into cramped equipment bays or portable devices. In everyday roles like cooling a mini-split or a pocket fridge, they remain impressively efficient. When price and footprint rule, rotaries often land the contract.

Scroll Compressor Strengths

Scroll models shine in energy use, so monthly power bills shrink. Their soft, near-silent hum suits homes and hush-hush offices alike. They also last longer than many rivals, which is why heavy-duty chilled water and refrigeration users prefer them.

Applications of Rotary Versus Scroll Compressors

Knowing where rotary and scroll compressors shine helps planners choose the best fit for each job. Because the two designs behave differently, engineers assign them to contrasting sets of operating conditions.

Rotary Compressor Applications

- Rotary compressors frequently serve tight spaces and residential systems. You can find them inside window and split-room air conditioners, where steady cooling in modest volumes is needed. Their small size and solid efficiency also power mini-fridges squeezed onto cramped shelves.

- You’ll see them in many dehumidifiers, steadily lowering humidity while keeping living and office areas comfortable. These traits, combined with a low upfront cost, explain why manufacturers lean toward rotary machines for everyday household appliances.

Scroll Compressor Applications

- Scroll compressors shine in larger, more demanding installations. Their energy-efficient, quiet operation makes them the go-to choice for central HVAC systems.

- They also feature prominently in heat pumps, delivering reliable heating and cooling throughout the year. In industrial refrigeration, scroll units tackle tough performance demands, proving their worth in commercial and factory settings.

Conclusion

Deciding between a rotary compressor vs scroll compressor does not have to feel overwhelming. By balancing key differences with your budget, efficiency goals, and acceptable noise levels, you can settle on a solution that delivers real returns. For expert guidance, and technical support, or to explore our top-tier models, visit VIBRANT Compressors, your reliable partner in compressor innovation.