Why Does Room Design Matter?

How to design an air compressor room? An air compressor works the same way: every pipe, filter, and bolt needs the right air, space, and temperature to run smoothly. If the room is haphazard, trouble follows, including:

- Overheating: Silent but deadly for efficiency and part life.

- Reduced Lifespan: Stress mounts when parts grind in bad air.

- Increased Energy Costs: Wasted power drains the budget.

- Maintenance Nightmares: Crowded layouts slow and even scare techs.

- Safety Hazards: Loud noise, weak vents, and hidden wires.

- Noise Pollution: Bad for staff comfort and local rules.

On the Flip Side, a Tidy, Thoughtful Layout Brings Clear Wins:

- Enhanced Efficiency: Cool, clean air lets the machine sip rather than gulp power.

- Longer Equipment Life: Keep your expensive machinery safe from wear and tear.

- Easier Maintenance: Open paths let technicians reach parts and finish jobs fast.

- Better Safety: A tidy, controlled space cuts many risks on the shop floor.

- Lower Operating Costs: Less downtime, smaller energy bills, and fewer repairs save cash.

- Cleaner Air Quality: Strong filters and coolers deliver dry, pure compressed air every time.

Ventilation and Cooling

Heat control is the heart of any compressor room. During normal operation, most compressors turn 75 to 80 percent of their electrical power into heat. Without fresh air and spot cooling, that heat builds up, forcing machines into thermal shutdown and speeding up expensive breakdowns.

Step-By-Step Guide to Designing an Air Compressor Room

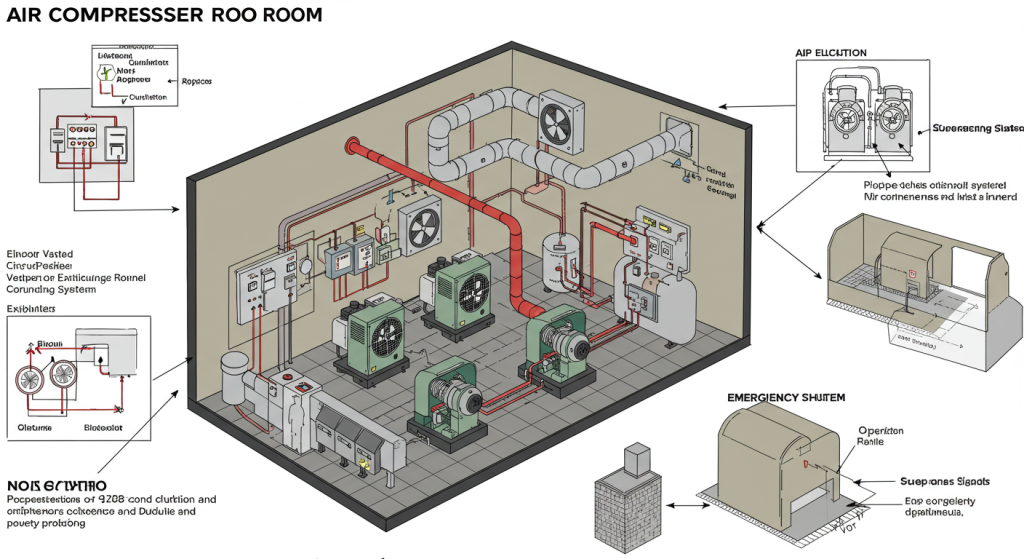

Step 1: Room Sizing & Layout

- Choose equipment types: rotary screw, reciprocating, dryers, filters, and an air receiver tank.

- Leave 1 to 2 meters of open space around every unit so technicians can squeeze in.

- Size the room large enough for a person to walk, kneel, and slide tools without twisting

- Run piping in a straight path with gentle slopes so water drains easily, and bends do not trap air.

Step 2: Ventilation & Cooling

- Give the room plenty of air in and out. Air-cooled compressors push nearly all their energy out as heat.

- Keep the room temperature rise below 4 to 6 °C (7 to 10°F) above outside air.

- Use intake and exhaust fans on opposite walls. Keep inlet speed under 4 m/s.

- When space is tight, add HVAC for the compressor room or use water-cooled units.

Step 3: Noise-Control

Compressors are loud, so noise reduction counts. Use these tricks to hush the compressor room:

- Sound-insulated wall and ceiling panels

- Acoustic doors and double-glazed windows

- Rubber isolation pads under bases

- Mufflers on all exhaust pipes

Test with a handheld meter on A-weighting. Aim for 85 dBA at operator stations.

Step 4: Electrical-Layout

- Follow NEC and local rules for conduit, grounding, and panels.

- Light the room with at least 10-foot candles where people work.

- Add emergency power, battery backup, and secondary circuits for alarms and fans.

Step 5: Drainage-Condensate

- Compressors drip condensate, so plan for it.

- Slope the floor toward a drain or trap.

- Install oil/water separators to meet the code and avoid fines.

Step 6: Fire Safety

- Install fire alarms, automatic sprinklers, and portable extinguishers.

- Surround machines with non-combustible walls and ceilings.

- Store rags, solvents, and other flammables more than 30 m (100 ft.) away.

Step 7: Foundation & Structure

- Compressors shake when they run, so pour a thick, isolated concrete pad or lay heavy, resilient rubber.

- Put each unit on a set of vibration isolators that can absorb side-to-side movement.

- Double-check that the room’s beams and floor can carry the compressor's weight and leave clearance for airflow openings.

Efficiency and Best Practices

How to design an air compressor room? Building an air-compressor room isn’t a one-and-done job; you have to stay alert and tweak things as demand changes.

- Energy Efficiency

- Variable Speed Drive (VSD) Compressors:

With airflow that goes up and down, a VSD unit speeds up or slows down the motor to match the need. Drop them into your rotary screw or piston setup and watch the electric bill drop.

- Leak Detection and Repair:

Tiny holes in hoses or fittings can suck the savings right out of your system, so schedule quick leak hunts and fix what you find.

- Heat Recovery:

Run ducts from the hot exhaust to warm the building or feed a process line; that free heat pays for itself fast.

- Maintenance Access and Planning

- Clear Pathways:

Keep aisles wide and doors clear, so technicians can slide in, check gauges, and tighten bolts without climbing over scrap.

- Tool Storage:

Set aside a tiny shelf or box for the wrenches, gauges, and bits you reach for every shift, so people spend less time hunting and more time fixing.

- Maintenance Schedules:

A well-planned room makes it easier to stick to preventive maintenance, which in turn stretches the life of your equipment. For more on solid industrial upkeep, visit Vibmac Maintenance Services.

- Monitoring and Controls:

- Compressor Controls:

Cutting-edge controls watch pressure, temperature, and run hours and will beep an alert when something is off. A central dashboard can even tweak the settings of several compressors at once, squeezing out extra efficiency.

- Remote Monitoring:

Adding remote eyes lets managers check compressor health from a phone or tablet, nipping overheating and other problems in the bud before they turn into costly downtime.

Conclusion

How to design an air compressor room? In that world, every draft cools worry away, every panel softens harsh noise, and every run of cable glows under safe, gentle light. That’s what an efficient compressor room looks like. It whispers, stays clean, and keeps running far past the usual retirement age. It ticks off every item on your checklist-from the latest room-design tips to solid advice on air-compressor foundations and fire safety. Visit VIBRANT.