What is an Air Compressor?

- What is the compressor air end, and how to choose? The compressor air end sits at the heart of an air compressor. Known by many names-the compressor element, the air-end assembly, or the screw block-this unit holds the rotors, bearings, seals, and tough casing that work together to squeeze ordinary air into high-pressure air.

- In a rotary-screw model, the air end packs one male rotor and one female rotor that spin in opposite directions. Air slips in through the inlet valve, gets wedged between the rotor lobes, and its space shrinks until the trapped gas is squeezed hard. A moment later, the high-pressure air bursts through the discharge port. This nonstop, steady flow is exactly what factories and workshops need to power tools and machines.

How to Choose Air Compressors?

- How well the compressor runs and how long it lasts almost entirely depends on the air ends design, oil flow, and overall build quality. Picking the right part, using it wisely, and keeping it serviced can save energy and push service life far beyond the average. So remember, folks, the air end is your machine’s beating heart.

- If you peek inside a good-air end, everything looks like a tiny puzzle made to fit perfectly. The rotors, seals, and bearings are cut and finished to such close tolerances that barely a whisper of space is left, letting air get squashed instead of leaking away. That tight, spinning dance is what turns atmospheric pressure into the strong, steady blast you’re after.

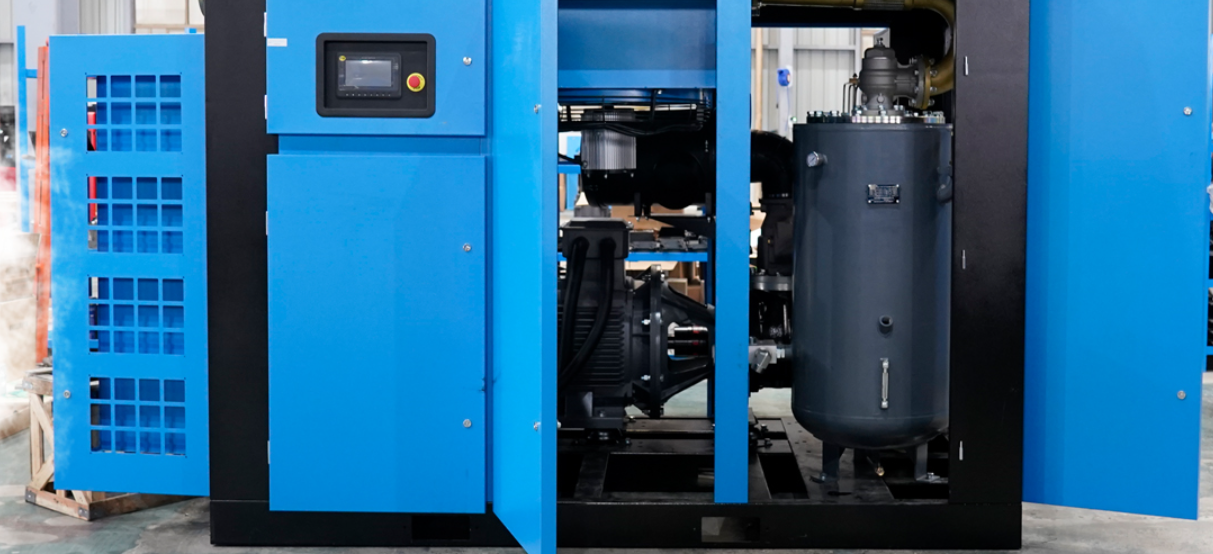

Parts of an Air compressor

Inside a rotary screw air end sit two twisting rotors that look like giant, intertwined corkscrews-one called the male rotor, the other the female rotor. Although they are shaped slightly differently, the two parts fit together perfectly inside a steel housing that keeps dirt and wear far away.

- Inlet Phase:

The moment the rotors spin, fresh air sneaks through a small inlet port and slides into the skinny cracks between the lobes. Those cracks form tiny pockets, or chambers, where air first starts its journey.

- Compression Phase:

Because the rotors never stop moving, the lobes slowly squeeze each pocket smaller and smaller. As the space shrinks, the air gets packed tighter, making the pressure jump. You could say the air is pushed, or screwed, along the rotor path while it lets out a very high-pressure hiss.

- Discharge Phase:

The second the target pressure lights up on the gauge, the thick stream of compressed air darts through the discharge port and fills the machine’s storage tank.

Because the whole process turns continuously like a smooth merry-go-round, screw compressors deliver air without the jerky pulses seen in piston units, an important perk for factories that run delicate tools and long production shifts.

The Very Important Job of Lubrication

Inside most rotary-screw compressors, a special fluid-usually oil-takes on multiple key jobs. That oil bath:

- Seals: It wedges into tiny gaps between the rotors and the case so compressed air can’t sneak back, keeping every breath of pressure useful.

- Cools: Squeezing air makes heat, and the oil soaks up most of it, letting parts run at a safe temperature.

- Lubricates: The slick film slides between bearings and teeth, cutting friction and wear, which stretches the air end’s working life.

- Muffles: Oil also dampens noise, giving the machine a quieter, friendlier presence on the shop floor.

How to Pick the Best?

What is the compressor air end, and how to choose? Choosing an air end isn’t about grabbing the biggest or cheapest piece on the shelf. It’s a game plan that affects your bills, output, and how long the whole system lasts. Use this quick guide to pick the air end that fits your work and budget, so you get the best return on every dollar spent. Here are the essential points to pick and check your air compressor:

1. Air Flow Requirement (CFM/m3/min)

– Tech Tip: This number matters most. Add up the CFM each tool or machine uses when running at the same time, then toss on another 10-20 percent for growth or surprise spikes. If the air end can’t meet the demand, pressure drops and headaches follow; if it’s too big, you pour money down the drain. That balance shows up in every performance chart.

2. Pressure Requirement (PSI/Bar)

– Tech Tip: Find out the highest PSI your toughest job needs. Most factory work asks for about 7-8 bar, or 100-116 PSI. If your setup exceeds that, search for an air end built to squeeze the gas into a steeper ratio.

3. Air Quality (Oil-Free or Oil-Lubed)

– Tech Tip: In some plants, air that smells like oil is a total deal-breaker.

– Do you make chips in a drug lab, pack sterile bandages, or assemble high-tech circuits? Then you need a Class 0 ISO 8573-1 oil-free unit because even a whisper of oil ruins the batch.

– For most factory tasks, like running pneumatic wrenches or blasting rust, an oil-lubed system fitted with good coalescing filters does the job and costs a lot less.

4. Noise Levels

Tech Tip: First, think about where the compressor will sit.

- Scroll air ends are naturally low on noise.

- Rotary screw air ends inside a cabinet can be much quieter than open piston machines.

- Noise is rated in decibels dBA, so if the unit sits near workers, a calm model or extra soundproofing matters.

5. Maintenance Requirements & Reliability

- Some designs open up fast for routine checks.

- Check how long each model lasts in the field. Solid bearings and tight seals cut surprises.

- Also, see if spare parts and skilled fixers are nearby when refurbishment is due.

Conclusion

Picking and caring for the right compressor air end takes know-how. Whether you need a new unit, help with sizing, or quick troubleshooting and repairs, working with a seasoned partner makes all the difference. When you need anything from top-grade air ends to hands-on service for your compressed-air setup, talk to the folks at Vibmac. Their long time in the business means they can steer you in the right direction and keep your system running smoothly. Visit VIBRANT.