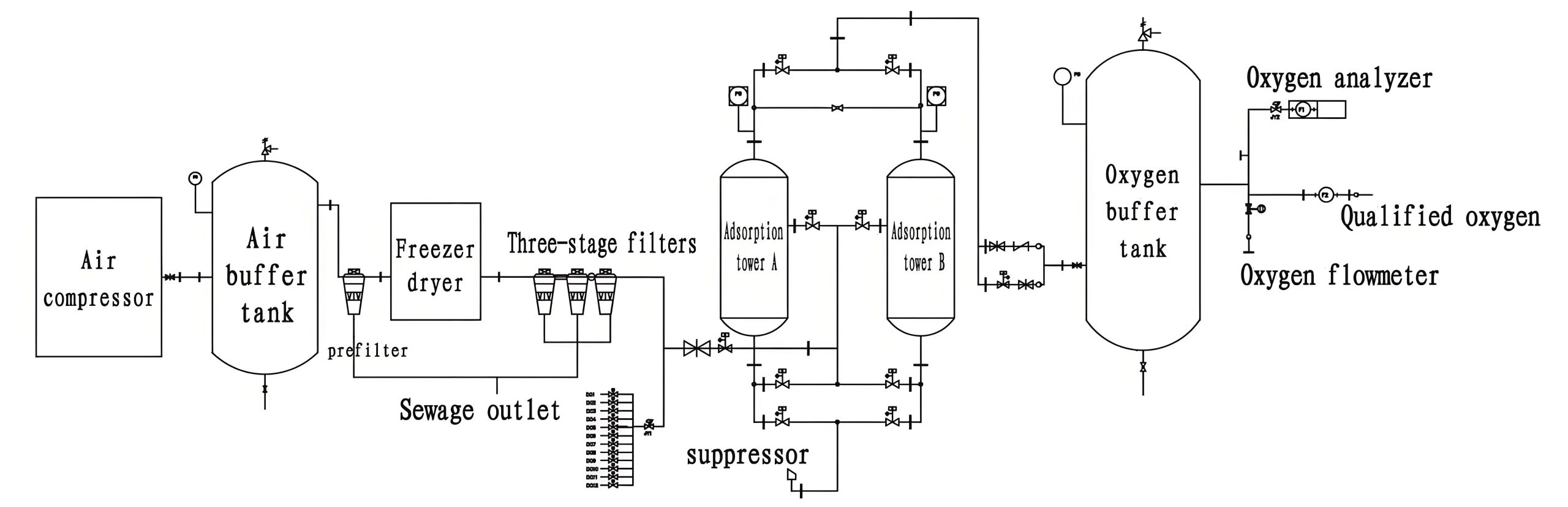

PSA Pressure Swing Adsorption Oxygen Generation Equipment

Dual adsorption towers, high efficiency, automatic monitoring and alarm, multiple configurations available

PSA oxygen generation equipment

The PSA oxygen generator has the advantages of low operating cost, high safety, simple operation and convenient maintenance. It is an economical, efficient and reliable on-site oxygen generation device, capable of meeting the oxygen demands of different users. It is an ideal alternative to traditional liquid oxygen and cylinder oxygen supply.

PSA Oxygen Generation

- Flow rate: 5~10000 Nm3/h

- Oxygen purity: 90~95%

- Atmospheric dew point: ≤-45℃

- P 0.05~0.8Mparessure: 0.1~0.4Mpa

- Dimension(L*W*H): customize

- Voltage: 220V/380V according to your country's voltage

- Weight: According to different plans

- Warranty: 1 Year

- Machinery Test Report: Provided

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now