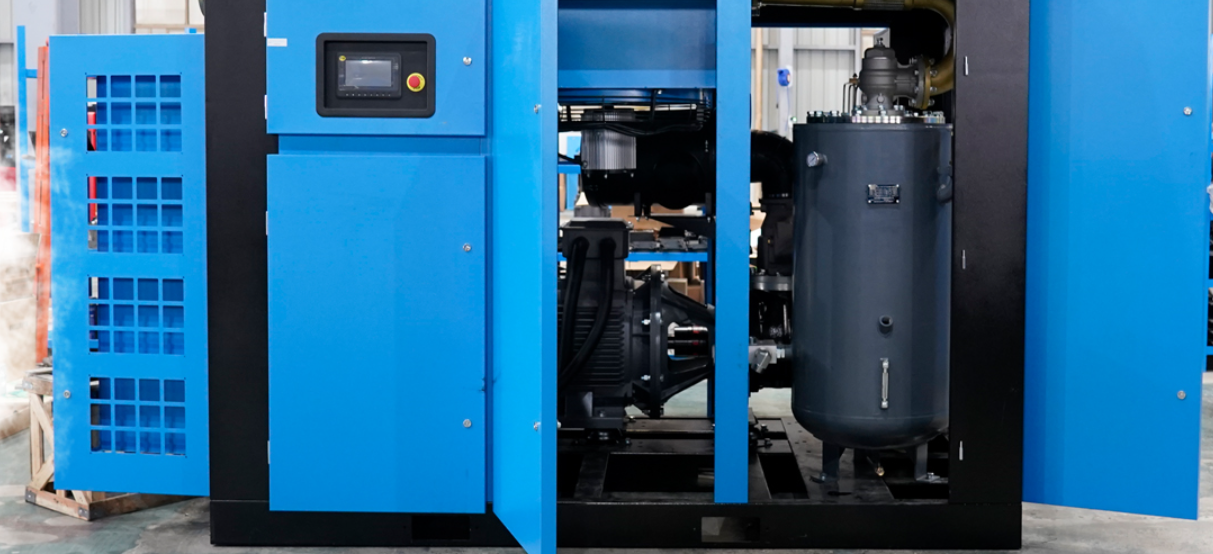

They assist with automotive servicing, metalworking, and construction by maintaining constant operation and providing nonstop compressed air, even in extreme conditions. The use of advanced noise and cooling Heavy Duty Air Compressor in Spain at rural and urban sites brings many benefits. Spain is one of the countries facing the brunt of rising energy prices. The rotary screw compressors CE marked and certified give Spain the advantage of significantly lowering carbon emissions, which is critical considering the situation. With the use of heavy-duty air compressors, Spain can achieve the air precision and safety needed. Spain’s business operations are now more efficient than before. The use of industrial compressors from VIBRANT has improved the business competitiveness of Spain.

Heavy-duty air compressors are suitable for:

- Increased air delivery.

- Increased uninterrupted run time with no need for cooling shutdown periods.

- Use of several air tools at the same time.

Two-stage air compressors – Spain’s Heavy-duty air compressor solution

Spanish two-stage air compressors are the country’s best-performing compressors, and in comparison to others, these are preferred in industrial applications for the ability to compress air in two stages.

The pneumatic power tools used in manufacturing, automotive, and construction industries in Spain need a stable and powerful air supply, servicing the latter. These industries use two-stage air compressors, which supply air and pressure, providing a longer service life and reducing wear of the internal components. Their design, though inefficient and costly on paper, ensures a high strain-to-power ratio because of the low power need, thus boosting their power efficiency.

To aid in reducing servicing downtimes, Spain’s industrial and agricultural regions heavily rely on two-stage air compressors. These industrial air compressors are rugged and irreplaceable in environments where near-continuous operation is crucial for productivity and cost-efficiency, which is critical in uninterrupted operation-dominated regions. To guarantee the rotor’s smoothness, stability, and durability, it undergoes dozens of refinement processes and adopts the most recent patented design.

Uses of Heavy-Duty Spain Compressors in Other Industries

The application of heavy-duty compressor in Spain is beneficial in other industries such as:

• Automotive: Impact wrenches, painting and inflation of tires, and air guns.

• Food Industry: Pneumatic packaging and sorting.

• Pharmaceuticals: System of pressurized air, oil-free.

• Construction: Pneumatic tools, drills, and jackhammers.

• Manufacturing: Systems for overhead and line production.

Best Buying Location in Spain: VIBRANT – Best Air Compressors Supplier

When in Spain, ensure VIBRANT is the first company you visit if you are looking for the best air compressors. VIBRANT is one of the most innovative, trustworthy, and affordable air compressor suppliers. VIBRANT is focused on becoming the world leader in Compressed Air Solution Systems.

Firm Expertise in Air Compression

Professional Compressed Air Technology is a marked advantage for Spain, enabling the country’s manufacturers and exporters to provide air compressors to industries, including automotive workshops, food processing plants, and the textile and construction industries.

VIBRANT also provides a complete compressed air system and ensures the company’s products are from quality control and assurance measures after sales, and R&D investments. Reliability, a long working life, and efficiency in operational costs make VIBRANT air compressors advantageous.

Why VIBRANT Is Still the Best Option for Investing in Spain?

VIBRANT serves compression products and marketing services to enable the industrial and commercial segments in Spain. This differentiating factor, VIBRANT, has been able to successfully penetrate the market. VIBRANT has not changed the market as the compressor distributor and continues to lead. We serve compression products and marketing services to enable the industrial and commercial segments in Spain.

Improper servicing diminishes Heavy Duty Air Compressors Spain’s reliability. Air compressors in Spain and other locations will always improve productivity, and regular servicing will always boost productivity. To improve air transport in Spain, the following measures will improve reliability for servicing the air transport system in Spain.

Maintenance reliability of the air transport system in Spain

Preventive Maintenance on Air Filter: Filters that are overdue for service will negatively impact airflow and operational efficiency. Air filter restoration optimizes airflow.

Preventive Maintenance on Air Leaks: Air leaks negatively impact operational productivity and energy efficiency. Productivity can be sustained on air systems by addressing and mitigating air leaks with leak detection spray or ultrasonic detectors.

Preventive Maintenance on Hoses and Belts: These parts are vulnerable to wear and have the potential to fail. Regular servicing improves an organization’s ability to stay ahead of unplanned equipment breakdowns.

For other air compressors, maintenance and vibration analysis, contact VIBRANT Servicing in Spain. A steadily maintained schedule increases the operational lifespan of air compressors and other equipment.

Benefits of Heavy-Duty Air Compressors for Spanish Industries

The Spanish industries are poised to benefit greatly from the new heavy-duty air compressors. For example, automotive repair shops located in Seville, as well as the manufacturing center in Bilbao, can now realize a boost in both productivity and operational reliability. Additional benefits of heavy-duty compressors include:

Enhanced productivity: Increased efficiency and productivity for all associated pneumatic tools and equipment, as all can operate simultaneously.

Uninterrupted service air: With stable pressure, machines can operate without the need to stop.

Decreased maintenance and breakdowns: These units are built to endure, leading to fewer breakdowns and greatly extended operational life.

Prolonged maintenance: The lower repair rates, paired with enhanced equipment life, coupled with reduced operational energy expenditure, result in long-term maintenance.

Spanish industries can now equip woodworking shops, construction firms, and automotive repair shops with air compressors, enhancing productivity and global competitiveness.

Conclusion

The installation of heavy duty air compressor in Spain industries serves to transform expenditure into significant commercial productivity and a marked increase in operational efficiency. An efficient air compressor will improve productivity, ensure compliance, and reduce costs. For tailored guidance, please contact VIBRAT for an industrial air compressor consultation. Looking for motivating tips on productivity improvement?