A screw type air compressor or a rotary screw compressor is a class of air compressor that applies two helical screws (rotors) to compress the air efficiently. It differs from piston compressors. It is less vibrating. Less noisy to operate. And air delivery at all hours. Ideal for:

•Round-the-clock industrialization

•Megawatt requirements of air volume

•Manufacturing lines and assembly lines

To understand more about the technology of the rotary screws, you may read the explanation in Kaeser.

Why screw compressor instead of others?

In industrial air solutions, the screw air compressors stand out among all the others. The rotary screw compressors, unlike the piston compressors, work in twin helical rotors that compress the air smoothly and continuously. This implies fewer vibrations, less noise, and high efficiency, which is ideal in heavy-duty work and continuous running.

- The 100 percent duty cycle of the screw-type compressors is one of the main reasons why industries utilize them. They have been designed to operate continuously without breaking down due to overheating, and thus their applications are in large-scale manufacturing, CNC machines, and packaging lines. Besides, they are oil-injected or oil-free to suit your application.

- Minimal maintenance requirements are also provided due to a reduced number of moving parts and highly efficient cooling systems in screw compressors. Variable speed drive (VSD) models also contribute to energy savings because airflow is conducted according to demand.

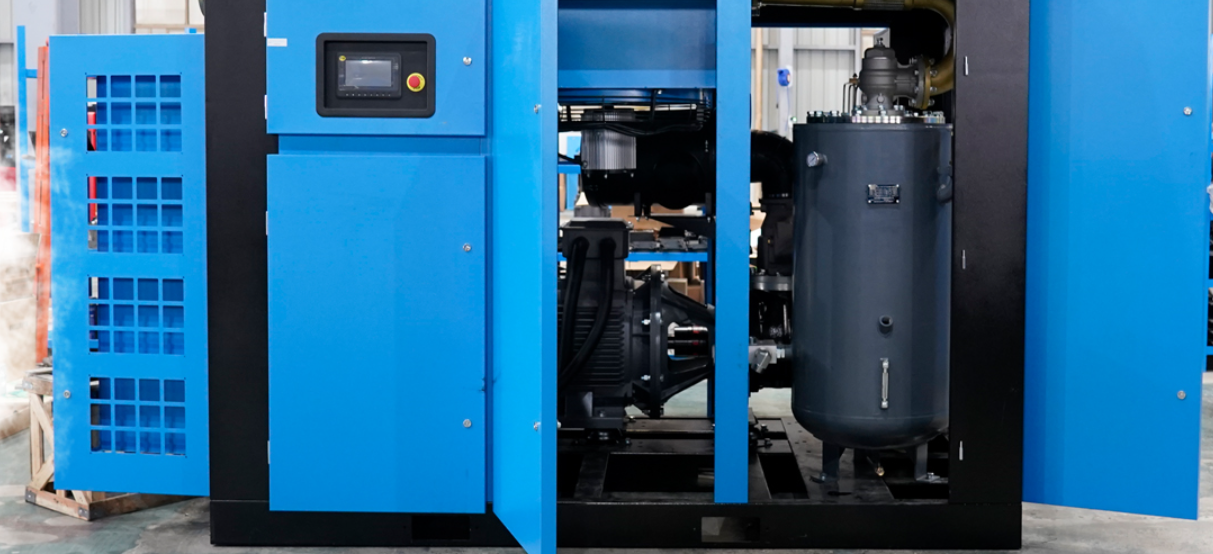

- Also, industrial screw compressors have an in-built aftercooler, dryer, and intelligent control system, hence a stable, complete, and total solution to compressed air.

- Screw compressors have efficiency, life, and affordability. Whether you require a small shop compressor or an industrial high-CFM, you will find that our compressors will provide many, many years of service.

Who Requires a Screw Compressor?

A screw type compressor is crucial in case you are involved in any one of the following industries:

- Drugs – where the cleanliness of the air is concerned.

- Textiles- in which the flow of air has to be uniform.

- Food Processing – here, noise and contamination are not allowed.

- Metal Fabrication (tools must be put under pressure at all times).

- Packaging Lines -When there is downtime, there are losses.

How to Buy Screw Type Air Compressors?

When you decide to alter your research about the screw type air compressors on sale, you must pay attention to the trustworthy manufacturer, which will provide you with great results in the long run and the ability to sustain the equipment at a low cost. VIBRANT, an air compressor screw type manufacturer for sale, is one company that stands out in the area and has found a well-established name in as far of production of air compressors is concerned.

- The essence of industrial development of modernity lies in the high-risk, energy-saving saving stable equipment. Air compressors, particularly screw air compressors that are innovative in having an intelligent system of operation, have transformed the way industries operate. Since the initial mechanical structures to the modern-day smart compressors, the idea of the invention has always been to make it more durable and cheaper to operate.

- VIBRANT has established itself as a key player in the change. Having a team of dedicated R&D, the company has state-of-the-art manufacturing facilities to integrate the latest technologies and materials to produce high-performance screw air compressors. They have products which are designed to support intense applications in construction, automotive, manufacturing, and the textile industry.

- VIBRANT is unique because of its customer-driven attitude. We have personalized market research and long-term contacts with customers, which are conducted by their engineers to realize the aims of figuring out what pains their customers, and to establish the actual solutions. VIBRANT compressors are planned out and programmed on computer-aided design and simulation software at every stage in the production process and development, to guarantee structural efficiency and optimum workings.

- Every product is thoroughly tested in terms of prototype with both lab and real-life tests of the performance. VIBRANT applies all the state-of-the-art diagnostic equipment and global test criteria to perfect each unit, to guarantee that every model passes or exceeds the test criteria necessary to industrial grade reliability.

Further, the screw air compressor made by VIBRANT is modern and has the following features:

Smart real-time control panels.

•More duty cycles with efficient cooling systems.

•Very low-noise Designs suitable for indoor and workplace.

•Slide-in configurations that suit your specific requirements.

Not only do they have good and strong compressors, but also those that are energy efficient to minimize operational expenses in the long run. Be it stationary/portable screw type air compressors you are seeking, VIBRANT is a one shop that provides you customized solutions with factory-direct prices.

VIBRANT is your one-stop shop when it comes to a screw type air compressor manufacturer that you use in the market. VIBRANT, with its world standards, innovations in design, and unparalleled after-sales service, is the name you can rely upon.

The Rewards of Shopping with a Company such as Vibmac

In case you are looking to seek out an OEM rotary screw air compressor manufacturer, then there is no better advantage than Vibmac, which is comparable to its competitors.

- The factory-direct pricing concept is that you never have to go through the middlemen-you get high-quality equipment at the most competitive rates.

- Heavy-duty models are developed to perform in continuous-duty, and therefore are suitable in heavy industrial environments.

- Through smart controller integration, it is easy to automate, monitor in real time, and control with precise standards, suitable for the modern factory setup.

- High efficiency motors have a long life span, less energy is consumed, and operation cost is minimized in the long run.

- Technical support is on offer, and the availability of spare parts is high, and you are assured of smooth running of your systems with minimal downtimes.

Vibmac, an air compressor screw type manufacturer for sale, is customer-oriented, innovative, and quality-conscious. Whether it is the superior design or after-sales service, it is in everything that the company has been able to show its dedication to excellence. Vibmac is an intelligent choice in screw type air compressor manufacturing as far as reliability, efficiency, and long-term value are concerned by business entities.

Conclusion

Your factory, tools, or production line needs a compressor that matches the speed. And that begins with the right choice of manufacturer. Do not be left with off-brand units and substandard after-sales service. Trust the Vibmac brand for efficient, long-lasting, and inexpensive rotary screw compressors. Looking forward to a quote? Visit VIBRANT, air compressor screw type manufacturer for sale, and get your quote today.