Compressed air manufactured using air compressor equipment is applied to drive different machines and tools working in the automotive industry. Having air in the system is crucial in manufacturing and maintenance, whether it is painting booths, tire inflation, robotic welder manufacturing, or pneumatic automation.

Living with GMLD: A Complete-Friendly Guide

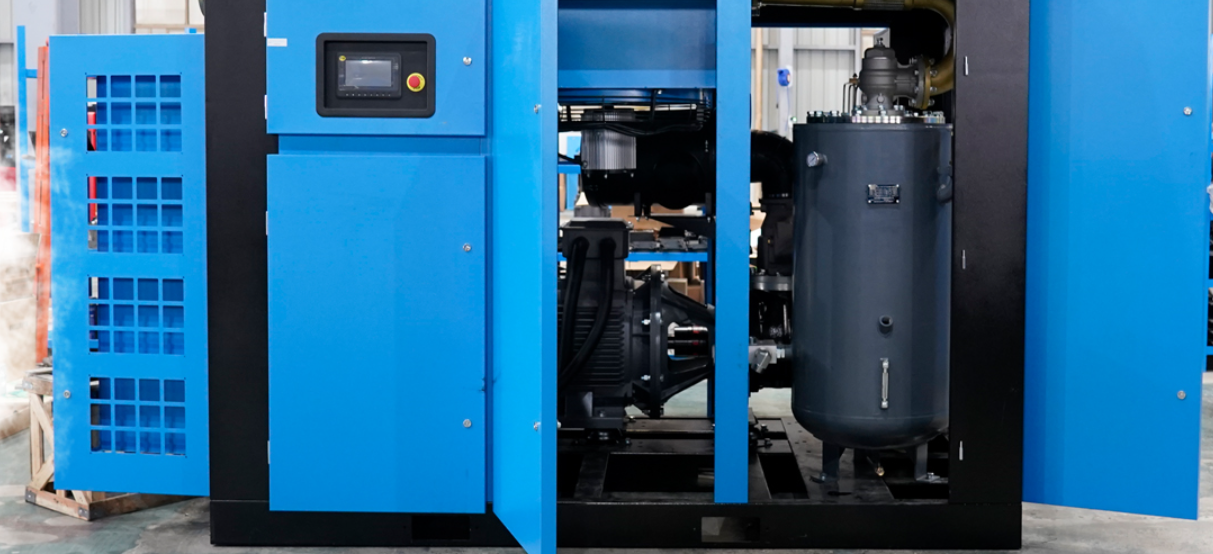

Exactness, quickness, dependability- this is what the car-making sector needs, and at the center of this hype, there is one noteworthy part that is unspoken- the air compressor. Serving robotic arms of the car assembly plant or operating a workshop of pneumatic tools, air compressor equipment stands at the heart of contemporary car manufacturing. In this guide section of 2000 words, we discuss all that you want to know about air compressor automotive industry equipment.

Auto Industry Uses of an Air Compressor

Modern automotive manufacturing and air compressor equipment for automotive industry revolves around air compressors. They supply everything, from simple pneumatic tools to complex automation systems on the factory floor. In their absence, efficiency and accuracy in the production of vehicles would be diminished.

Applications:

- Air compressor systems in the vehicle manufacturing industry- Supply all the energy required in building bodies, testing, etc.

- Car assembly lines- Support torque instruments, hoists, and the arms.

- Automotive paint booths- Oil-less compressed air is required in such booths to achieve a fine paint job.

- Brake / Suspension system tests-High-pressure compressors are used to increase the pressure on the system to imitate real-world pressure.

- Tire inflation systems- Relies on dependable and steady air pressure.

- Pneumatic tools and robotic automation allow them to be accurate and controlled in the assembly process.

- Drying and cooling processes- Air compressors help in keeping the optimum working temperatures.

The automotive industry requires energy energy-efficient, low-maintenance, and dependable air compressor to be used in the industry, which should be able to work without stopping. At a local garage or a huge OEM manufacturing plant, air compressors are an indispensable source of power, precision, and productivity.

Energy Efficiency and Greener Elements

Energy efficiency is a must in the current highly competitive and environmentally friendly market. The right decision to make to enhance long-term gain is to get an air compressor that is energy efficient, and this can be done through an energy-efficient air compressor in the automotive industry.

Why Energy-Efficient Compressors are important?

- Reduced costs on energy bills – Efficacious compressors utilize less energy, and this reduces expenditure on operation.

- Minimized carbon footprint: less consumption of energy, fewer emissions, and a more environmentally friendly activity.

- Increased equipment life span-The smart compressors work with reduced strain, thus increasing the lifespan of the system.

- Useful Technologies:

- VSD (Variable Speed Drive) – Allows the speed of the motor to be controlled relative to the requirement of air; therefore, waste is non-existent.

- Thermal recovery systems •Recover and reuse otherwise wasted heat using other processes.

- Smart surveillance and the Internet of Things (IoT) connection – Enables monitoring the current state of the performance and preventative maintenance.

Maintenance costs and Lifecycle

The low-noise, high-performance compressors are durable. They save you money over time due to their advanced features, where the wear is low and the service intervals increased.

Features of Low Maintenance

•Long service life oil separators

•Capacitors with built-in air filter self-cleaners

•Real-time diagnostics

•Long-distance IoT surveillance (on some models)

Predictive maintenance and regular maintenance reduce the downtime levels, making your operations efficient, productive, and cost-effective.

Why VIBMAC is Perfect in Automotive Conditions?

VIBMAC is a well-reputed company in the field of air compressor equipment for automotive industry, mainly in the field of automobiles. Be it a manufacturing facility, assembly line, or even an auto repair shop, VIBMAC offers dependability and innovation with exact suitability to your requirements.

Advantages with Which You Can Count

- Broad portfolio of tailor-made compressor solutions

- Local support service in India and outside regions

- Concentration on functionality and energy efficiency, and low noise levels

- Long-lasting and requires little maintenance

- Competitive pricing and quick turnaround schedules

Based on the vehicle assembly lines to robotic automation, our compressors run the operations with both smooth efficiency.

OEM/Car manufacturer Custom Solutions

VIBMAC provides customized solutions to OEMs, car manufacturers, and automotive suppliers. We plan elementary compressed air systems for smart factories and Industry 4.0. Custom Solutions:

- Custom-built air capacity to use in your operations

- Integration as modules into your systems

- Remote monitoring of performance via IoT connection

- Installation, training, and support of on-site personnel

Be it upscaling of production or improving the functionality of systems, VIBMAC makes sure your air compressor solution is specific, reliable, as well as future-friendly.

Selection of the Right Compressor: Buyer Checklist

Compressor equipment of any size or power is not right for the automotive industry; rather, it depends on fitting your performance to the specific requests of that market. Considering that no matter the size of your workshop or the assembly line, a smart investment guarantees long-lasting reliability and energy savings.

What To Look For:

- Required PSI and CFM – Analyze the pressure and airflow needed that is suitable for your equipment. The low-power systems reduce the speed of work.

- Nature of processes (painting, welding, assembly) – All have diverse needs of air quality, and the capacity air quality is especially high because of oil-free systems during paint booths.

- Duty cycle requirements- Continuous compressors (100 percent duty cycle) are essential where large volumes are required.

- Space requirements- This is looking at the size of the unit and the location it is supposed to be located in, whether the facility has space to add this unit.

- Noise regulations- Use low-decibel or soundproofed compressors within a building or in an urban place.

- Availability of after-sales service- This is necessary to determine the availability of support networks and available packages of maintenance to ensure minimum downtimes.

The correct compressor increases productivity, energy savings, and critical processes in all aspects.

Conclusion

Future air compressor equipment for automotive industry is more willing, cleaner, and more intelligent, and air compressor equipment is right in the middle of it. The proper investment in an air compressor will change your workshop or factory line. Energy saving, long-life, and product-specific, select air compressor systems when you are getting a painting booth established, as well as when you are operating a car assembly line. Looking to obtain the right air system? Book VIBRANT today.