- A Variable speed drive air compressor is a complex air compressor that modifies the speed of the motor to match the real demand of the compressed air. VSD compressors are dynamically modulated in contrast to the traditional fixed-speed compressors that are operated at fixed speed without regard to air demands. This will make sure that the amount of energy consumed is only as much as needed to reduce wastage and increase performance.

- The VSD system uses a frequency inverter compressor and variable frequency drive (VFD) control to give a stable supply of air pressure. This has enabled industrial applications in Brazil to enjoy the benefits of energy-saving compressor solutions, optimized compressor performance, and low power consumption which resulting in huge savings in the cost of electricity.

Major Benefits of Variable Speed Drive Air Compressors in Brazil

Energy Conservation and Economy

- Energy efficiency is one of the greatest benefits of VSD air compressors in Brazil. The VSD systems do not operate at full capacity continuously, in contrast to fixed-speed compressors that can operate at full capacity. This is an effective load control of air compressors, which guarantees that the consumption of energy is reduced.

- These systems avoid unnecessary surges of energy as the level of motor speed modulation and soft-start compressor technology ensures smart energy management and maximum performance. The industries that have implemented the use and Advantages of variable speed drive Air compressors in Brazil have indicated that the use of this system has saved up to 30-35% of energy as compared to the traditional system.

Dynamic Industrial Demand Adaptive Airflow

- VSA Compressor is efficient in processes that have variable air requirements. This allows it to have constant air pressure at all times by adjusting the airflow to meet the dynamics in the production cycles. This flexibility will guarantee the reliability of compressed air and eliminate overloading that may lead to wear and tear.

- The manufacturing industry, construction industry, and automotive industry are some of the industries that have benefited from this aspect because downtime is minimized, productivity is boosted, and the compressor life is prolonged. VSD compressors could be of great benefit, especially to the industries in Brazil, where the efficiency in operations directly reflects the competitiveness.

Less Maintenance and Long Life span

VSD compressors are designed smartly, which helps in reducing the maintenance needs and wear and tear. These compressors can run at variable speeds, thus eliminating stress and strain normally associated with fixed-speed systems.

Maintenance Benefits Include:

- Potential of predictive maintenance by way of integrated control systems.

- Less mechanical rotary screw compressor stress.

- Greater periods between service cycles.

- Lower operational costs

The above characteristics render VSD compressors an affordable compressed air package solution to industrial businesses in Brazil.

Optimized System Reliability and Performance

Variable speed technology is used so that the compressors can be kept operating in the optimum range. By using advanced compressor control systems, the operator will be able to monitor performance, track energy usage, and set alerts to avoid inefficiencies.

Benefits Include:

- Constant air pressure on delicate operations.

- Disciplined manufacturing operations.

- Grasping Brazil's industrial automation systems.

- High productivity and industrial reliability.

This reliability is extremely important to Brazilian manufacturers who depend on the constant supply of compressed air to high-precision equipment.

Sustainability and Environmental Benefits

The industries in Brazil are becoming more geared towards sustainability, and VSD air compressors are the best fit for this objective. These compressors cut down on carbon emissions and hence lower the environmental impact through decreased energy usage.

Environmental Benefits:

- Compressors with reduced carbon footprint.

- Adherence to energy efficiency laws in Brazil.

- Environmentally friendly compressed air.

- Sustainable industrial operations.

VSD technology makes a good economic choice and helps Brazil to pursue its overall environmental goals.

Various industries VSD Air Compressor Technology

Variable speed air compressors in Brazil are flexible, and hence they are good in a broad spectrum of sectors. It is beneficial to the various industries as follows:

- Manufacturing Industry

Automated machinery also needs air pressure that is uniform among manufacturers. VSD compressors are industrial air compression systems with flexible motor technology, and therefore, machines can run at their best without energy wastage.

- Automotive Industry

The car factories are subject to variable volumes of production. VSD compressors achieve a constant air pressure control so that the assembly line can operate smoothly because of variable air demand handling.

- Textile Industry

Compressed air is relied upon in the textile production of delicate machinery. Smart air compressor systems offer efficient air supply and cuts on energy expenses, which promotes the productivity of industries.

- Medical Industry

Precise and reliable air supply is required in hospitals and manufacturers of medical equipment in Brazil. VSD compressors guarantee reliability in compressed air and exceed the requirements in operational and energy efficiency.

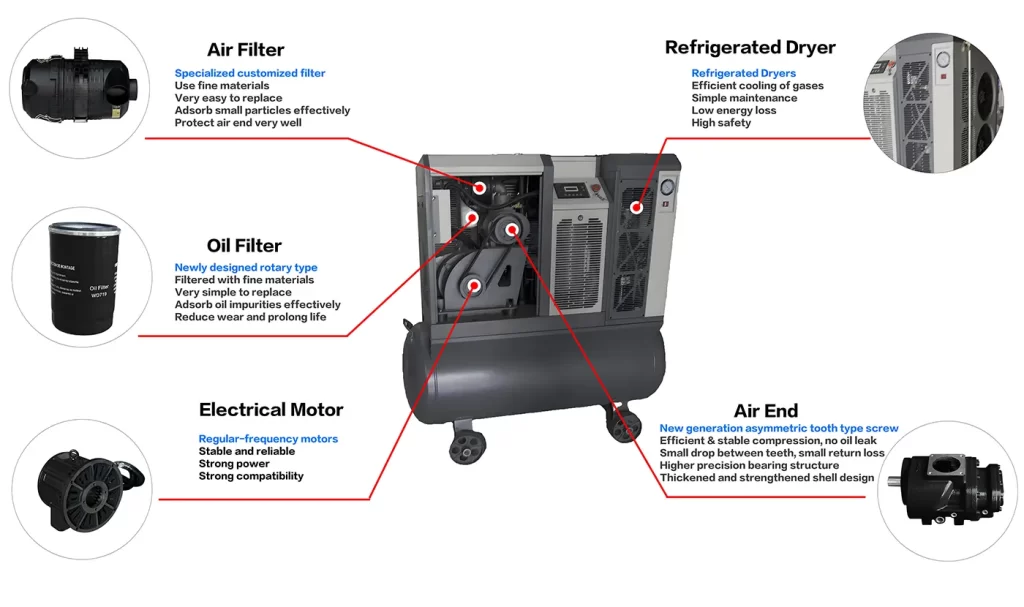

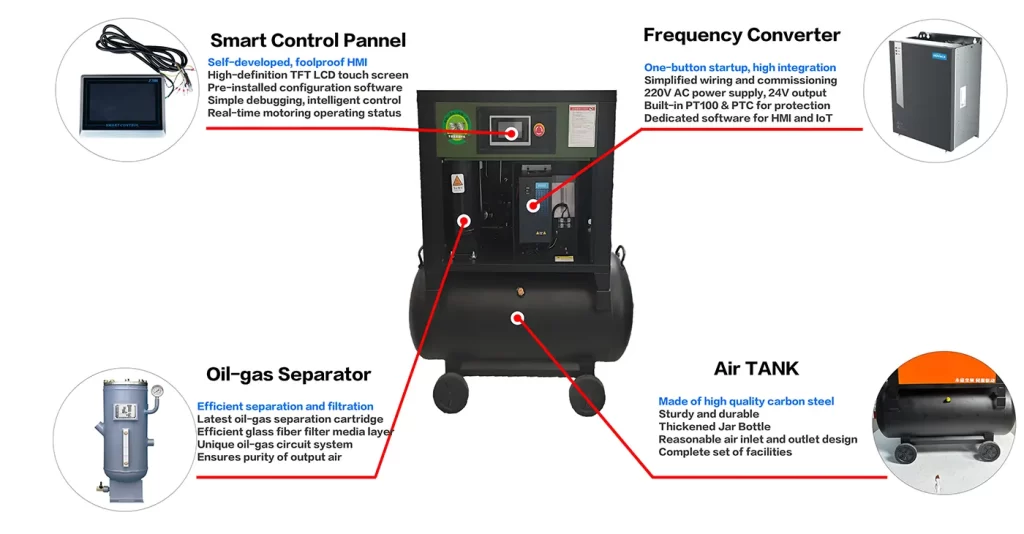

Product Feature: VIBRANT Variable Speed Air Compressors

VIBRANT will focus on offering the most innovative, quality VSD air compressors to Brazilian industries. Such compressors are made efficient, long-lasting, and convenient.

Product Features:

- Adaptive Motor Technology: Modifies RPM due to real-time air demand to achieve the best energy consumption.

- Energy Savings: Uses less amount of power than normal fixed-speed compressors.

- Less Wear and Tear: Minimizes the strains on the parts when there is low demand.

- Integrated Control Systems: Sophisticated monitoring and alarm system increases reliability and avoid inefficiencies.

High performance and long-term savings in operational costs are highly beneficial to industries that are manufacturing, medical, and textile, among many others, where the application of VIBRANT compressors can be of great benefit.

Best Practices in VSD Compressors Implementation in Brazilian Industries

- Evaluate Air Demand Patterns: The insight into air utilization at your facility is the cornerstone to successful VSD.

- Get Smart: Converter compressors to industrial automation Brazil systems to monitor and control more efficiently.

- Periodical Maintenance: Predictive checks can be used to ensure that the performance is optimized even in cases of low wear.

- Train Operators: Educate employees on the concept of variable speed technology to gain the most.

- Check Power Consumption: Monitor and use power-saving compressor solutions to monitor and minimize the electricity bills.

Conclusion

Advantages of a variable speed drive. Air compressors in Brazil are a must-have investment for industries in Brazil that seek to minimize operational expenses on energy consumption, minimize energy costs, and guarantee a steady air pressure. With such a decision as the use of VIBRANT VSD air compressors, Brazilian manufacturers can not only optimize compressed air systems, but also accept the solutions of industrial equipment that are based on environmentally friendly and energy-efficient solutions that guarantee long-term profits and sustainability.