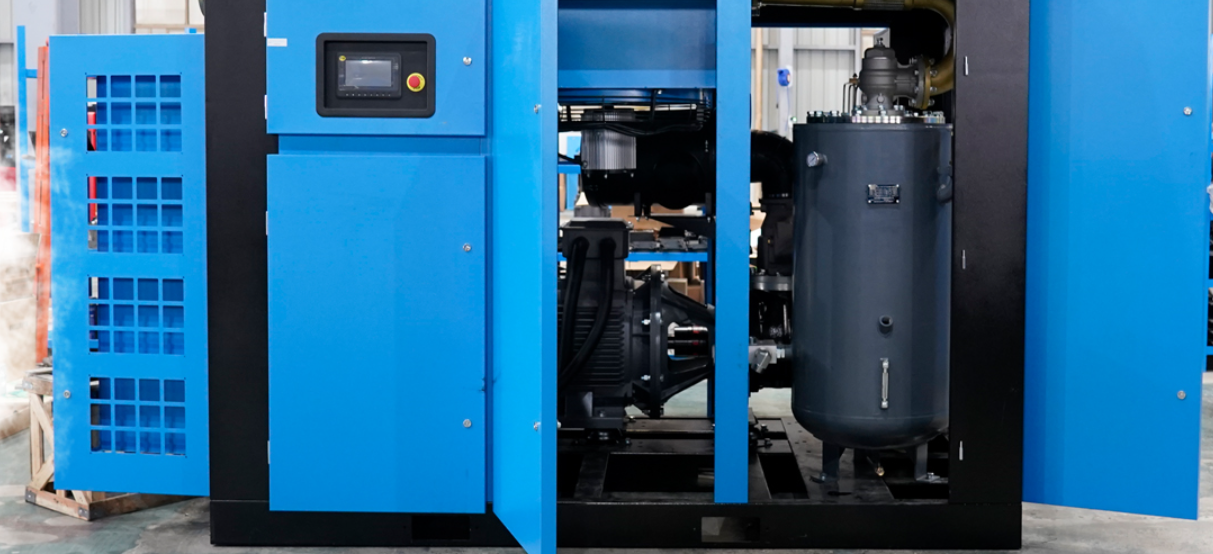

Sneaking into the center of the flourishing industry in Brazil, there is a part that is not being witnessed to be revolutionizing the industry it is part of; the air compressor. One of the prime tools of machinery, powering, streamlining, and energy-cost-reduction, the Air Compressor for Industry in Brazil is not purely a device, but a strategic investment.

Why Air Compressors Matter in the Brazilian Industrial Environment?

Industries in Brazil are various, i.e., food processing, automotive, construction, and petrochemicals. All these depend on the use of compressed air systems to operate well without any problems. The Brazilian air compressor market is on the rise as more players require energy-efficient air compressors in Brazil that can facilitate large-scale production without losses.

Why are the Two-Stage (Low Pressure) Air Compressors Perfect in the Industry in Brazil?

Efficiency, reliability, and savings of energy when choosing an appropriate air compressor in the industry in Brazil are important. Low-pressure two-stage air compressors provide just the right performance and cost factors, especially in industries where the need to maintain a flow of air at a lower scale of pressure is mandatory.

The Prime Low-Pressure, High-Efficiency

Two-stage low-pressure air compressors are designed to compress the air in two stages. In the initial phase, the air will be compressed to an intermediate pressure and subsequently cooled. When the second stage takes place, it is recompressed to the intermediate pressure. Such an approach enhances energy efficiency greatly, which lowers the cost of operations in factories and plants in Brazil. These compressors are suited to those applications where air under low pressure is utilized continuously, e.g.:

- Painting booths: spray painting

- Material handling technology

- Pneumatic tools and automation

- Produce and beverage processing

These systems do not support motor overloading; rather, unlike single-stage units, they do provide steady airflow. This qualifies them to use in Brazilian industries working in hot and humid environments where consistency is the key to performance.

Conservative and Long-lasting Design

Among the outstanding characteristics is the fact that such compressors are focused on energy savings. The more people are under pressure, the less effective they are not always productive–and low-pressure systems demonstrate it. Even efficiency is not lost in regard to energy saved, as pressure output is tempered to the actual operational requirements. As it is constructed using rugged industrial-grade components, these systems require minimal maintenance and are very resistant to harsh conditions. It is a win-win situation in terms of uptime of production and long-term costs.

Reputable Air Compressor Equipment in Brazil

VIBRANT has a great commitment towards providing industry over Brazil high- level air compressor performance. The two-stage, low-pressure models are constructed considering different industrial outlooks of Brazil, which guarantees good performance in the textile, medical, and manufacturing businesses. Our proud products:

Handling of raw material & processed material- industrial Sector

• Textile Industry

In search of bespoke air-compression systems? We are in a position to guide you in making the right choices of the most energy-efficient system that suits your business needs.

To know more about power-saving air compressors in Brazil, please check out Atlas Copco or VIBRANT today.

Competitive Advantages to the Brazilian Industries

1. More Efficiency New compressors improve the flow of air, thus increasing the overall efficiency of the plant.

2. Lower operational costs Energy Energy-efficient compressor technology can reduce electricity bills by as much as 30 percent.

3. Improved Tool Performance Air-powered tools perform better and have a longer service life when kept supplied with air.

4. Reduced Downtime High-end systems with appropriate service make no interruptions, making them very useful in the manufacturing plant’s air systems.

Selecting an Appropriate Supplier of Air Compressors in Brazil

Choosing the right air compressor dealer in Brazil is crucial for avoiding lapses in operations and overall effectiveness of the facility in the long run. The correct supplier sells equipment, not a solution, whereby it provides a comprehensive answer to your industrial requirements.

Seek a provider that has a deep industry experience, a wide response service network, and a complete portfolio of compressors. A perfect supplier will provide:

- Bespoke set-up to suit the requirements of your operation

- High technical support that would minimize downtime

- Whole package services such as installation, training, and maintenance

In VIBMAC, we are much more than machine suppliers; we establish business relations. We are among the leading suppliers of industry, encompassing high-quality air compressor systems of high quality air performance in Brazil. Our compressors have worked hard to gain a reputation for durability and energy efficiency in sectors such as food processing to heavy manufacturing industries by virtue of their robust control systems.

Due to that, we know that Air Compressor for Industry in Brazil has unique air needs. That is why we provide high-capacity innovative compressors and 24-hour assistance to make your systems look good.

How to Keep Your Compressor in Good Order?

You need to maintain proper maintenance of an air compressor properly to ensure that it works well and prolongs the life of your compressor. A well-maintained system works more efficiently, uses less energy, and less unforeseen blackouts. To make the best of your equipment, consider these professional maintenance ideas:

•Check frequently for on-air leakage, rust, and corrosion, particularly at the valves, hoses, and fittings.

•Changing filters and oil as recommended by the manufacturer will eliminate the buildup of dirty air supply.

•Monitor the force of pressure and airflow regularity to be warned about a performance problem before it gets out of hand.

Check-ups will enable you to identify the small problems before they escalate to a highly demanding fix. But outsourcing maintenance is very useful to many industrial operations.

That is where VIBMAC comes in. In Brazil, we provide professional maintenance of air compressors that match your needs in the industry. The routine checks, prevention, and care, as well as emergency repairs, are all provided by our qualified technicians to keep your operations running around the clock. In automotive, manufacturing, or packaging, we can promise that your system will be running virtually optimally with little disturbance to your processes.

The Brazilian Industrial Air Market Trends

The trend is increasing the demand for energy-efficient air compressors in Brazil, which is attributed to:

• Increase in the cost of electricity

• Regulations about the environment

Invest in pneumatic controls directed toward automation

The Brazilian industries are drifting towards continuous airflow systems and more intelligent monitoring devices that monitor efficiency in real-time. In Brazil, this industry requires investing in the correct air compressor.

Conclusion

The process of selection of the Air Compressor for Industry in Brazil is not only acquiring the device, but rather a long-term business investment. This includes everything, such as the management of compressed air demand as well as automation using pneumatic controls. When you have VIBRANT as your reliable partner, you will get far more than equipment; you will be assured of peace of mind. To get smarter, stronger, and more sustainable air compression solutions to power your plant, contact us today.