What is an Air Cylinder Compressor?

An air cylinder compressor is a type of compressor that is also known as a piston air compressor or a reciprocating air compressor. It is defined as a machine that compresses atmospheric air into a storage tank by means of a piston that moves back and forth within a cylinder. The most common use of this compressed air is to power pneumatic tools, spray paint, operate machinery in industries such as automotive and aerospace, and inflate tires.

How Does an Air Cylinder Compressor Work?

Air Intake Phase: Air comes in through an air filter, which will block dirt and other debris from contaminating the compressor.

Compression Stroke: A piston moves downward, creating a vacuum which draws air into the cylinder sleeve.

Compression Phase: The piston further moves upward, which leads to further compressing the air.

Discharge Phase: The compressed air, in turn, is forced to a storage tank with a check valve.

Safety First: There is a pressure switch that controls the system and a safety valve that prevents overpressure.

Typical Uses of Air Cylinder Compressors

Air cylinder compressors can be found in use from the workshop to the factory because of their:

• Automotive: Spraying paint, changers, wrenches, and impact tools.

• Food & Medical Industries: Air that is clean, particularly the oil-less models.

• Industry: Worked with pneumatic machinery on automated assembly lines.

• Construction: Devices such as jackhammers, sanders, and nail guns.

• Workshops & DIY: Work with wood, cleaning parts, and tire inflation.

Air Cylinder Compressor Maintenance Tips

To ensure that safety is maintained while also enhancing the unit's lifespan, proper care is needed. Here are ways to enhance the functionality of the device.

Daily Checks:

•Keeping an eye on noise levels and pressure gauges.

•Drain the air tank of moisture, especially if the environment is humid.

Week

•Replacing or cleaning the filter that captures air.

•Look at the wear-afflicted belts if the unit is self-driven (on belt models).

Month

•For the models that use oil lubrication, check the oil levels.

•Check sleeve cylinders and piston rings.

Year

•Conduct regular maintenance, including changing check valves and safety valves.

•Do a detailed examination of the motor and pump of the compressor.

Specialized Applications: The Best Air Cylinder Compressor

The best air cylinder compressor for low-pressure air systems is the Pressure Air Compressor. With precise energy-efficient airflow and low operational noise, this type of compressor is a wonder in industries that require a continuous and precise supply of air at lower pressures.

Tailored Airflow for Specialized Applications

These features make them suitable for low-pressure operations that require constant air supply and include but aren’t limited to:

•Spray painting

•Tools requiring compressed air

•Aquaculture

•Food processing and textile industries

•Assembly of electronic components

Unlike their high-pressure counterparts, low-pressure models focus on optimizing output instead of sheer force, delivering the perfect flow of air without flooding the system.

Convenient Set Up and Transportation

A very appealing feature of a low-pressure air cylinder compressor is its lightweight and portable design. These compressors are:

•Convenient to carry between workstations,

•Easily configurable in different layouts and

•Fit for operations in small confined areas.

The portable compressor is ideal for small factories, laboratories, and mobile service vehicles where the ease of use provided by the compressor is unmatched by bulky traditional systems.

Low Noise Operation for Sensitive Areas

Noise is a common problem in most professions, which is why the low-pressure air compressor is designed to feature:

•Audible emission control,

•Reduced vibration, and

•Quiet performance during prolonged use.

This makes it ideal for use in medical facilities, offices, workshops, and schools that have quiet environment needs.

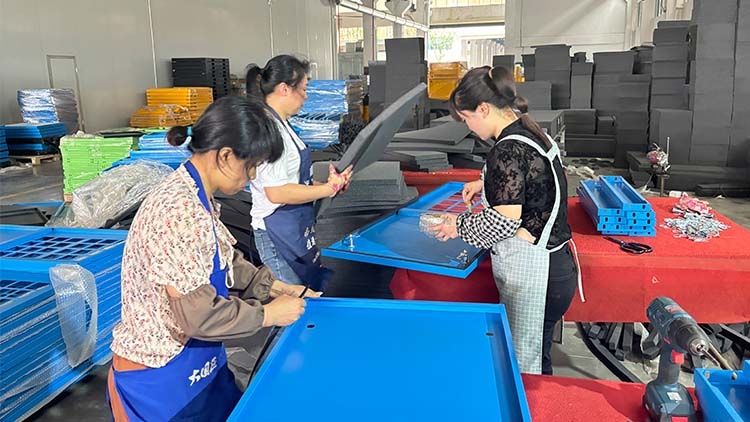

Advanced Noise and Vibration Dampening Technology

To further reduce disturbance during operation, the compressor is manufactured out of highly elastic damping foam that:

•Alleviates vibration,

•Isolates operational shock, and

•Reducing environmental noise impact.

Not only does this technology enhance comfort in the workplace by reducing vibration, but it also increases the longevity of the compressor and other nearby machinery.

Consistent Airflow with Low Energy Consumption

The low-pressure air compressor provides one of the best benefits in its class, taking air delivery with high consistency and low energy consumption. These systems are:

•Constructed to allow soft-start operation by means of frequency conversion.

•Designed to control mechanical shock during startup.

•Able to reduce energy expenses while maintaining operational productivity.

The achievement of effectiveness at minimal impact on performance makes these systems compressors a necessity for businesses willing to invest operational capital.

Low Maintenance Cost and Downtime

Also, this compressor, because of its technology of frequency conversion soft start:

•Low mechanical and operating disturbances.

•Increase the operational lifetime of the device.

Reduced maintenance requirements increase productivity by decreasing spending time on servicing the equipment. This makes the equipment ideal for companies looking for reliability that allows the users unattended performance from the compressor.

Interstage Pressure Control With High-Efficiency Compression

Efficiency is not one-dimensional. Performance on various load conditions is factored into the equation as well. The low-pressure compressor employs smart interstage pressure control in order to:

•Keep the ideal working condition

•Minimize energy expenditure from over-compression

•Get closer to isothermal compression, which is the ideal compression model

Due to this, the compressor can meet different demands without sacrificing operability and efficiency.

VIBRANT – A top-rated brand for Air compressors

We at VIBRANT work towards providing the world with the most durable, energy-efficient, and cost-effective air compressors. In our efforts to deliver as a trusted air cylinder compressor manufacturer, we aim to:

•Deliver effective compressed air systems

•Help reduce your energy and maintenance expenditure

•Assisting you with strong service and support after the sale

For your convenience, we are selling the WEG motor at the lowest price, making sure that your system is powerful yet inexpensive.

Why Choose VIBRANT Low-Pressure Air Compressors?

• Maintains Consistent Airflow for all low-pressure usages.

•Lower operating costs with Energy Efficient Design.

• Flexibility across industries due to Compact and Portable units.

•Increased lifespan of the unit and quieter operation for less comfort noise and vibration.

• Peak efficiency in all conditions with Smart Control System.

• From a builder with a global reputation, therefore guaranteed High-Quality Build.

Conclusion

More than just a mechanical element, the air cylinder compressor serves as the heart of every compressed air system. Understanding the functionality, components, and maintenance of the unit offers value to professionals such as mechanics, factory operators, and even DIY enthusiasts. With so many choices available, are you still in need of a provider for industrial air cylinder compressors you can depend on? Explore Vibrant Full Range Here!