Introduction

Every manufacturing facility depends on various systems for streamlined operations, and breakdowns are often caused by compressed air systems. Due to their heightened costs, this powerful resource goes untapped. A solution such as the Compressed Air Management System can help resolve these issues. With Vibrant expertise, industrial operations can achieve optimum control and efficiency and reduce operational costs. Let us explore how an intelligent integrated air management system can optimize your facility’s performance.

What is a Compressed Air Management System?

A Compressed Air Management System is an integrated solution consisting of controllers for air compressors and IoT-based monitors that enable real-time insights and automatic adjustments for improved energy efficiency. These systems offer advanced features such as:

• Duty cycles of the compressor

• Load/unload control

• Sequencing control systems

• Pressure control

• Flow monitoring

• Forecasted predictive maintenance

To summarize, these systems are digital operators that manage air systems.

The Importance of Managing Compressed Air Systems

From an industrial standpoint, compressed air systems remain one of the costliest utilities, yet they are often overlooked and neglected.

- Put simply, the absence of a well-functioning compressed air system management hinders operational productivity with regard to energy utilization expenditures, efficiency, and overall costs. Based on the provided data, the Department of Energy estimated that system inefficiencies, inadequate maintenance, or obsolete practices account for about 50% of compressed air system air wastage.

- Smart air management systems incorporating leak detection and maintained pressure optimization are capable of curtailing energy expenses while reducing wastage. Compressors operate during low-demand periods, which trigger pressure inconsistency, maintenance neglect, and counteractive compressor cycling. These recurring issues that stem from a lack of scheduled preemptive maintenance can be resolved by a professional compressed air audit.

Core Technologies within Compressed Air Management Systems

Aside from other key technologies, an integrated industrial air compressor management system includes the following:

1. Air Compressor Control Units:

These units enable load balancing and sequencing between multiple compressors.

2. Remote Supervisory Control for Compressed Air Systems:

These devices monitor and provide feedback on pressure, temperature, and flow over the internet.

3. SCADA Systems:

The Supervisory Control and Data Acquisition Systems (SCADA) provide data visualization, fault alerts, and performance logging.

4. Compressors with Variable Speed Drives (VSD):

These compressor systems optimize motor speed and operate on demand.

5. Smart Sensors:

- Pressure measurement devices

- Thermal measuring devices

- Flow measuring devices

You can learn more about SCADA for compressed air from Schneider’s electric SCADA solution.

Operating Cost Reduction with Increased Energy Efficiency

What is the primary focus? In the case of compressed air systems, energy efficiency should be the objective. Because this is a large portion of industrial energy spending, these systems need improvement.

A properly functioning system allows for:

• Alert notifications and leak detection.

• Optimization of energy consumption by air compressor machines.

• Improved control of idle time.

• On-the-fly responsiveness to real-time demand delivery of compressed air.

• Recovery of waste heat from compressors.

Predictive maintenance focuses on managing the compressors and other components of the system before they pose any threats.

Data regarding the compression can be obtained through cloud management systems, making access possible from any part of the world. Decision-making is enhanced significantly.

Applications in Industrial Automation

The integration of air systems into industrial automation frameworks creates intelligent factories. Automated notifications and information retrieval enable the systems to focus on alternative production shifts rather than just responding to pressure decreases.

Automation incorporates everything from managing rotary screw compressors to reciprocating compressor systems.

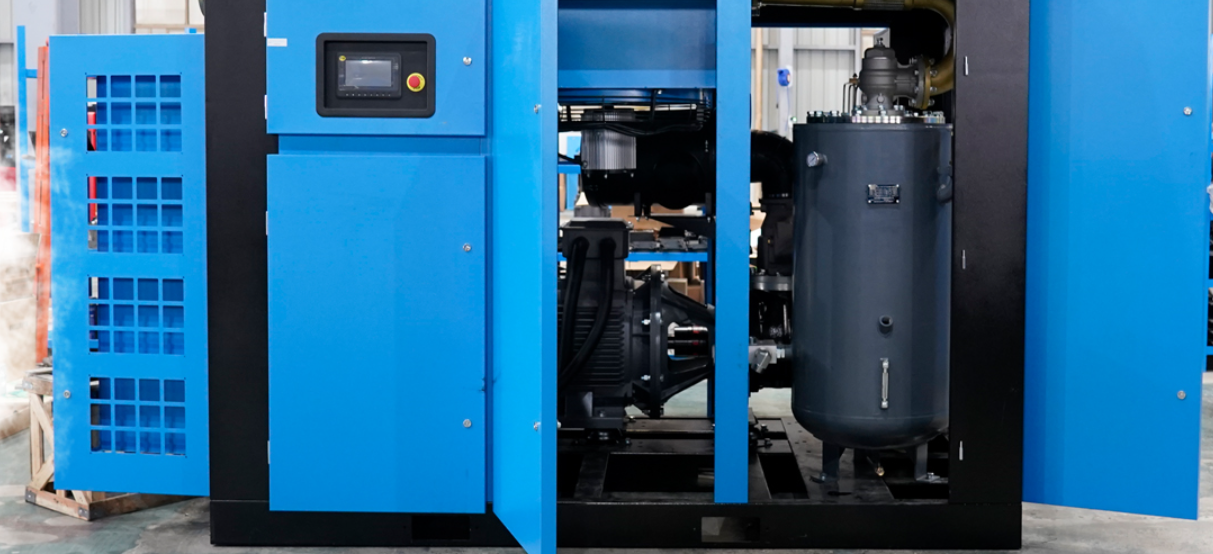

Elements of a Fully Managed System

An optimized system consists of:

• VSD (Variable Speed Drive) Compressors

• Air Dryers – Desiccant or Refrigerant Type

• Air Filters

• Air Receivers or Storage Tanks

• Piping Systems (of high-grade quality)

• Integrated management software for air compressors (integrated systems)

Every component plays a vital part in the compressed air production and delivery processes.

Benefits of Implementing a Compressed Air Management System

In addition to what was mentioned above, operations within the facility are automized and more efficient. These are the advantages:

• Improved Productivity

Having stable and controlled air pressure eliminates pressure drops and machine interruptions during peak operations.

• Improved System Reliability

Optimized operations lead to process improvement. Planned activities minimize breakdowns while enhancing equipment longevity and reducing emergent work.

• Optimization of Processes

Real-time demand monitoring with smart systems eliminates unneeded production and adjusts air output, resulting in overproduction. Every delivery of compressed air is calibrated and delivered with precision.

Productivity in Manufacturing

Doing more work with compressed air as a resource is a task that takes less physical work and energy. This translates into increased productivity per kilowatt hour.

Eco-Friendly Approaches

It is simpler to adopt eco-friendly approaches than it used to be. For the organization, operating cost reductions directly translate to a lower carbon footprint through diminished electricity consumption.

Reduced Costs of Operations

Streamlined run cycles, repairs, and energy watching, all spending lead to operational cost reductions and significant savings over time.

How to Select Wisely?

In one critical aspect, systems will differ. It is important to select a compressed air management system that is appropriate to your facility’s compression demand. Do consider the following pointers:

1. Scale of Your Compressor Network

Centralized control and sequencing may be necessary for larger plants. Smaller configurations are better served by modular systems.

2. Energy Use Evaluation

Assessing your current energy expenditure reveals potential areas for improvement.

3. Type of Compressor

Each type – centrifugal, rotary screw, or reciprocating compressor – comes with unique optimization requirements.

4. Required Level of Automation

Do you want a fully automated system with remote access features, or is basic monitoring enough?

5. Collecting Information Specifications

For real-time analysis, SCADA, IoT devices, and other relevant analytics dashboards can be integrated into the system.

6. Compliance with Regulations

Confirm that your facility meets OSHA safety requirements and the ISO 50001 industry standard.

Best Practices for Implementation

To support the change, these actions should be taken:

• Carry out energy auditing.

• Deploy zone pressure sensors.

• Use adaptive optimization.

• Interconnect with the facility’s EMS.

• Teach operators the software dashboard functions.

• Conduct periodic maintenance.

Check out the Compressed Air & Gas Institute Best Practices Guide for more detailed, tailored approaches.

Return on Investment and Cost Consideration

Like in any other case, there are expenses. But the ROI? Exceeds expectations by far.

• Initial expenses: Purchasing equipment and software; installation.

• Operational savings: Energy expenses reduced by 15-30%.

• Reduction of downtime: Improved by up to 40%.

Conclusion

An advanced compressed air management system enhances a facility’s operational efficiency while driving the organization toward energy efficiency, significant operational excellence, and overall substantial cost savings. The smart controls of the system with real-time leak detection and monitoring systems reduce energy waste, prolong equipment lifetime, and comply with stringent sustainability policies. Take advantage of VIBRANT system design, optimization, and management services to help you regain control of your compressed air systems. Learn about the energy-saving practices and solutions related to compressed air systems offered by us.