What is the Conversion m3/min to cfm Chart?

This unit records the volume flow rate in metric terms. It tells you how many cubic meters of air or gas pass a given point each minute. It’s the imperial equivalent favored in the United States and many other engineering circles. It simply counts how many cubic feet of air or gas move through the same point every sixty seconds. This guide sets out to clear away any mystery around switching the about convert m3/min to cfm chart.

Cubic Meters Per Minute (m3/min): The Go-To Unit for Flow

Cubic meters per minute, written as convert m3/min to cfm chart, belongs to the International System of Units and measures how much three-dimensional space a moving substance fills every minute. It means one meter-sized cube of liquid or gas crosses a set spot every sixty seconds. You will meet m3/min in situations like these:

- Massive HVAC rigs: working out how quickly fresh air moves through skyscrapers.

- Factory lines: tracking chemicals, steam, or cooling water as it slips from step to step.

- Environmental watchdogs: measuring smokestack output or the streams the plant sends back.

- Underground mines: keeping tunnels drafty enough for miners and machines to breathe.

Because its base unit is metric, changing from liters per second or hours to m3/min is quick and rarely errors.

CFM: The Cubic Foot Per Minute

Crossing over from the metric camp, engineers often turn to the cubic foot per minute or CFM. One CFM equals one cubic foot passing a fixed spot in exactly sixty seconds. CFM shows up wherever quick air flow details matter, including:

- HVAC in homes and offices, to size fans, ducts, and chillers.

- Compressed-air setups, naming compressors, and feeding tools.

- Cars and bikes, to check how much air an engine swallows.

- Hand vacuums and shop units, as a shorthand for pull power.

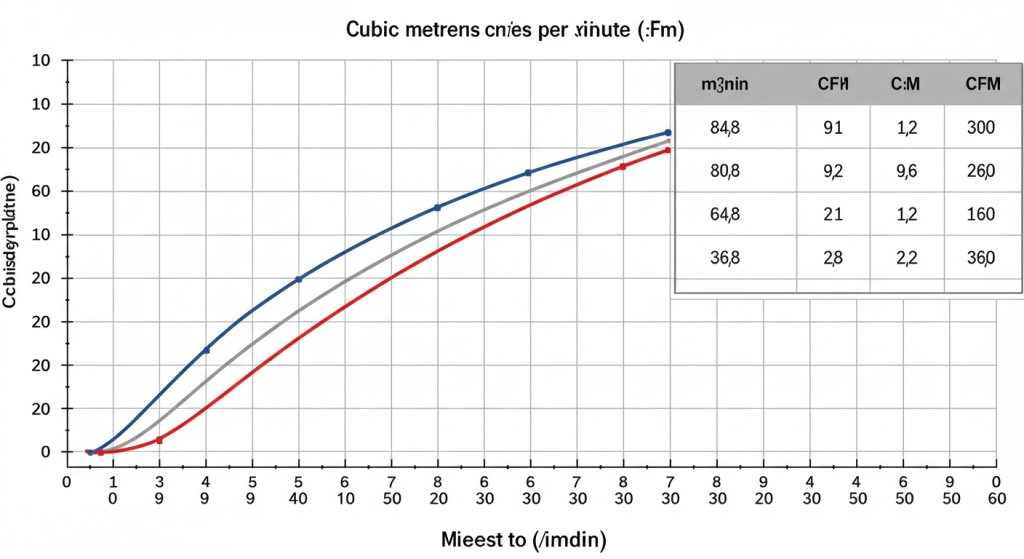

The Power of Visuals: Embracing the m3/min CFM Table

Yes, the math is solid, but when a job is buzzing around you, a printed m3/min to CFM table can save time and headaches. These handy sheets take the basic formula, run it through a dozen typical flows, and lay the answers side by side in a glanceable grid so you don't need a calculator or a smartphone.

Pro Tips for Accurate Air Flow Measurement

- Stop guessing; always use a calibrated flow meter at the duct exit.

- Tiny leaks eat pressure, so hunt and fix them before you log numbers.

- Convert for the conditions that exist, not just the brochure specs.

Why a Conversion Chart is Indispensable?

· Instant Reference: No brain-busters or fumbling for a calculator- just look and the number pops up.

· Reduced Errors: Quick sums done under pressure tend to go sideways. A ready chart cuts that chance.

· Field Convenience: Great for engineers, techs, or crews knee-deep in a cabinet with no Wi-Fi.

· Planning and Design: Handy during the blueprint stage so you can line up specs in a flash.

Using One of These Sites to Switch m3/min to CFM Couldn’t Be Easier:

1. Open a trusted conversion site or type m3/min to CFM into a search bar.

2. Find the Cubic Meters per Minute box on the page.

3. Key in the number you want changed.

4. Hit the Convert or Calculate button.

5. Just like that, the CFM result appears on-screen.

Where Does Accurate Flow Conversion Shine?

Converting m3/min to cfm chart into CFM on the fly isn’t trivia- it’s routine across many trades. When everyone speaks the same figures, machines mesh, output rises, and rules stay met.

1. HVAC Systems and Air Flow Conversion:

This is perhaps the most familiar use of flow calculations. Heating, ventilation, and air conditioning engineers face airflow questions daily. Whether sizing ducts, picking fans, or checking air quality, knowing how much air moves is vital. When a design draws in metric figures but must pair with imperial fans or filters, quick conversions keep spaces comfortable and efficient. A small slip can leave the room stuffy, ruin air quality, or waste energy.

2. Compressed Air Systems:

Compressors are rated by the volume they deliver, usually in cubic feet per minute. When new tools come with specs in cubic meters per minute, converting to CFM tells you if the existing unit can meet demand. Get it right, and tools run smoothly; get it wrong, and pressure drops, productivity suffers, and extra costs pile up.

3. Chemical and Process Engineering:

Inside a chemical plant, a steady flow of raw materials, finished goods, and carrier gases keeps production on course and guards quality and safety. Reactors, pipes, scrubbers pieces of equipment need a set volumetric flow to function as designed. Engineers meet specs in both metric and imperial units daily, so converting flows becomes second nature on the shop floor. When the numbers line up, stoichiometry holds, yields improve, and crews handle flammable materials without fear.

4. Wastewater Treatment and Environmental Control:

In wastewater facilities, aeration systems depend on precise air-injection volumes to feed the microbes hard at work. Specs may call for 20 m3/min; if the blowers speak CFM, a quick swap of units keeps oxygen levels where they belong. Get it wrong, and treatment stalls, regulators frown, and the river pays the price. The same principle applies when factories report stack flows; turning them into standardized terms is what keeps a clean sheet.

5. Mining and Tunnel Ventilation:

Getting enough fresh air into a mine or tunnel and stripping out deadly gases can keep people alive. So the fans and ducting there have to push huge air quantities, usually noted in m3/min.18 When you mix parts from different makers or tweak a design to fit local codes, swapping flow numbers between units becomes vital for safety and for staying on the right side of the inspectors.19

Conclusion

If you work with compressors, fans, or any air-powered gear, overlooking unit swaps is a costly gamble. The quick m³/min to CFM chart below helps you match systems, lift output, and cut mistakes. Whether you’re an engineer, technician, or buyer, a solid grasp of this shift keeps your projects on track and delivers better results. For more details, visit VIBRANT.