Introduction to Steam Quality, Efficiency, and Uses in Industry

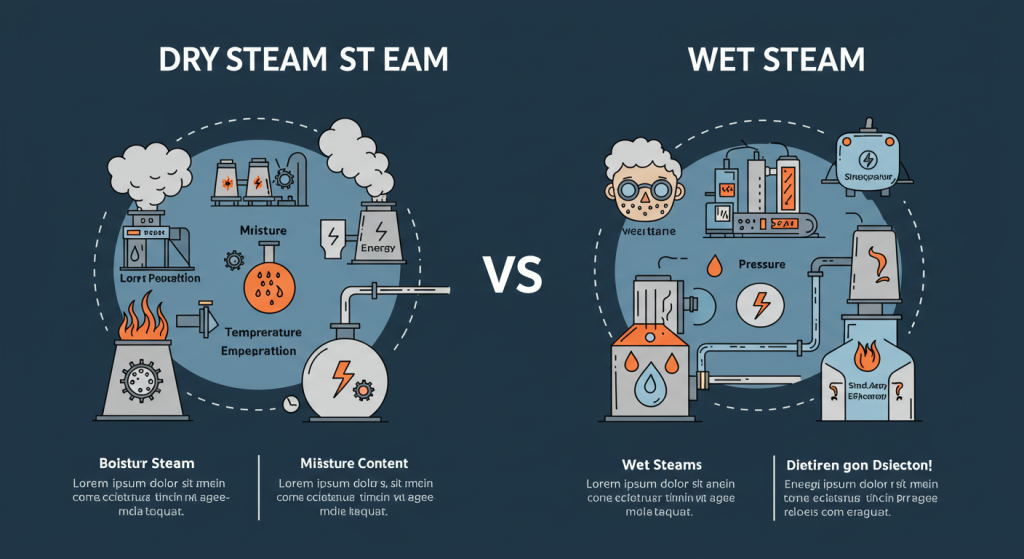

- In industrial processes, steam is one of the most commonly used forms of energy. However, different processes require different types of steam. In the context of assessing the efficiency, safety, and functioning of equipment, comparisons of dry steam vs wet steam require consideration. The objective of this article is to expose the data relevant to the application, its merits and demerits, system optimization, and other technical details.

- Steam devoid of associated water particles is termed saturated steam. Dry steam, as the term indicates, does not have water droplets and rather, is completely devoid of water. This allows dry steam to be used for heating and sterilization as it has high specific energy.

Essential Characteristics of Dry Steam:

- Also known as the dryness fraction, it is 1 (or 100%)

- The latent heat of vaporization is high.

- Water particles in the form of entrainment do not exist.

- Energy transfer, the effectiveness of steam is highly efficient.

What is Wet Steam?

Wet steam consists of steam that is a mixture of vaporous and liquid water in the form of tiny droplets. It arises when the saturated steam loses heat while condensing insufficiently in the boiler system. Wet steam is represented as a cloudy mist and is ineffective in heat transfer.

Key Properties of Wet Steam:

• Dryness fraction < 1 (for example, 0.9 or 90%)

• Reduced latent heat because of the increase in water content.

• Higher maintenance costs combined with chronic inefficiencies.

• May cause erosive damage to machinery and water hammer damage.

Steam Quality: What is the Dryness Fraction?

The dryness fraction defines the clearness of steam. It is the ratio of the mass of steam to the total mass of steam and water.

• Dry steam: 1.0

• Wet steam: <1.0 (for example, 0.85 means 85% steam and 15% water)

In industrial applications, the quality of steam is critical. A higher value of the dryness fraction means better heat exchange and reduces the possibility of destruction from corrosion.

Steam’s Thermodynamic Properties

- Optimizing industrial processes requires consideration of steam in its various thermodynamic states. Dry steam vs wet steam differ in their phase composition and moisture content, which relates directly to their performance and efficiency.

- Dry steam has a dryness fraction of 1.0, which means it is fully dry with no moisture content. Steam is said to be wet when its dryness fraction is below 1.0. Wet steam differs from dry steam as it contains small water droplets. The moisture reduces thermal efficiency and can harm industrial equipment over time.

- The auxiliary of dry steam is the latent heat, which is the energy required to change water into vapor without a temperature increase. For wet steam, some portion of the latent heat must be released, causing a reduction in thermal capacity.

- Dry steam is more effective because it has a higher total heat content and is more helpful in improving heating and mechanical work compared to wet steam. Wet steam is denser because to contains more liquid, while dry steam is less dense because it occupies more space per unit mass.

- The efficiency of wet steam is lower because of the specific heat of the moisture the steam contains. The steam is more destructive to steam lines and turbines because of the reduced heat transfer efficiency caused by the moisture.

Uses of Dry Steam

Dry steam is required when high efficiency is needed, along with low moisture content.

• Sterilization in medicine and pharmaceuticals

• The processed food industry

• Drying textiles

• Steam turbines to prevent blade erosion

• Steam tracing in oil and gas pipelines

Uses of Wet Steam

While wet steam is often regarded as a byproduct, it can also be found in:

• Old or inefficient boilers

• Poorly maintained steam systems.

Humidification methods that do not require effective heat transfer.

1. Low Heat Transfer Efficiency

o Heat loss with water droplets in steam is significant.

o Water droplets decelerate steam loss, and therefore heat loss is decelerated.

2. Corrosion and Erosion Problems

o Moist air can promote rust and damage to pipelines.

o Turbine blades and valves also suffer from corrosive damage.

3. Water Hammer

o Extremely dangerous bursts of steam pressure create loud and dangerous noises.

4. Higher Maintenance Costs

o There are extra costs associated with maintenance for the broken pipes and other equipment that require servicing, and components that require repair and replacement.

Improving Steam Quality Hinges on the Design, Installation, and Maintenance:

• Install Steam Separators: Remove water from steam lines.

• Use Steam Traps: Prevent downstream movement of condensate.

• Boiler Maintenance: Routine maintenance and tuning help enhance steam dryness.

• Insulate Steam Lines: Minimizes heat loss and steam line condensation.

Superheated Steam: An Advancement Following Dry Steam

When the pressure on dry steam is maintained at a certain level, heat may be added, transforming the steam into superheated steam. This form of steam is completely devoid of water droplets and is in a fully vaporized state, thus containing more energy. Superheated steam is most beneficial for processes that require constant energy, such as:

• Steam turbines

• Power generation

• High-temperature drying

Moisture can often damage important mechanical parts or components, such as sockets. Equipment reliability is enhanced when superheated steam is utilized. The drawback to this is that, compared to dry saturated steam, superheated steam is poor in heat exchange. This property makes superheated steam less effective for processes that require rapid changes in temperature.

Flash Steam and Energy Recovery

The reduction of high-pressure condensate results in the formation of flash steam. This resource can be utilized to:

• reduce energy waste

• Lower fuel costs

• minimize emissions

Flash steam recovery increases overall steam system efficiency. Check out our energy-saving tips on compressed air systems for other ways to improve efficiency.

Steam Boiler Performance Indicators and Types of Steam

Your steam type affects boiler performance. Wet steam leads to:

• Fuel wastage

• Disruptions to heat transfer processes

• Increased maintenance costs

Conclusion

Dry steam vs wet steam can work in tandem, but modern industrial steam systems will benefit much more from dry steam. It improves the efficiency of heat transfer, lowers maintenance requirements, and increases the longevity of equipment. Wet steam, which is common with outdated systems or poorly designed systems, can cause uncontrolled system failures due to system oxidation, erosion, uncontrolled corrosion, and energy loss. Improved steam regulation leads to greater operational safety and energy efficiency, resulting in lower costs over time. Go to the VIBRANT steam systems page for bespoke professional recommendations.