Energy efficiency in today's competitive industrial world is not a matter of choice anymore. Energy-saving Air Compressor in Russia is becoming an important part of operations as businesses seek a cost-effective use of electricity and a positive fundamental productivity. In the manufacturing, automotive, or construction industry, the correct air compressor can be the key to continuous, consistent compressed air with the minimum consumption of energy.

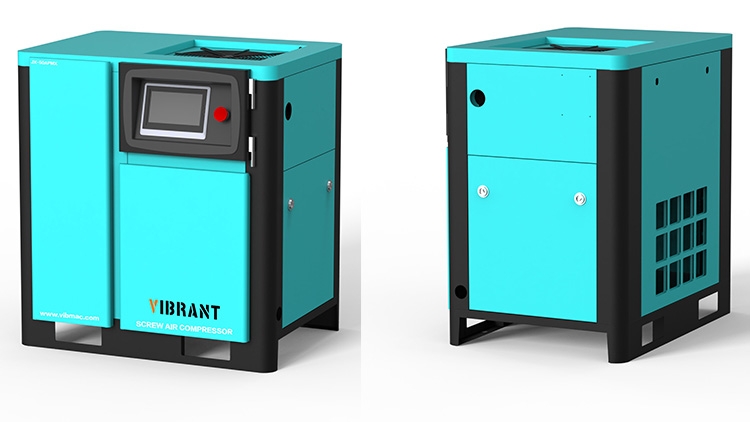

Best Solution to Air Compressor in Russia: PM VSD Screw Air Compressor

Optimum precision control

The PM VSD screw air compressor integrates a permanent magnet motor and a variable speed drive (VSD) so that it offers accurate air flow with reduced energy usage. Its autonomous self-optimizing speed control variably responds to air demand in real time, therefore minimizing power consumption and operating costs. This renders it suitable for industries in Russia that need steady performance with energy-saving solutions.

Operation is Quiet and Stable

This compressor has low sound, which also makes it applicable in indoor enclosures and noise-prone areas because of its sophisticated design and quality components. It is highly stable under load and can continuously be used in high-demanding industrial environments.

Durability and high-level Reliability

The PM VSD compressor is made of high-strength material, hence long-lasting. It is built with high-powered capabilities designed to withstand heavy-duty conditions that are well-suited to automotive, manufacturing, and industrial applications. The long-lasting design also ensures little chance of downtime, therefore, maintaining high productivity.

Minimal maintenance Costs

The compressor has a longer life span due to low power consumption and high-quality components. The service life is very long, and as such, the replacement parts are minimal, resulting in low operating costs.

Green and Energy Advantages

The PM VSD compressor emits low levels of emissions and gives good-quality compressed air. The Russian industries can reduce their carbon footprint by using energy energy-efficient format in consuming electricity. This renders it economical in the creation of a sustainable product, a viable option to corporations that are environmentally inclined and that focus on green industrial solutions.

Versatile Applications

Applicable to motor production, automobile assembly, and non-specific industrial processes, this compressor provides reliable and standardized yet high-quality cryogenic air output with maximum levels of energy optimization. It is the best option that any business would undertake so as to integrate performance, sustainability, and cost savings.

What reasons to pick an energy-saving air compressor in Russia?

Russia has an energy-efficient air compressor, and it is very beneficial in various ways compared to traditional systems. New compressor modern technologies, including rotary screw air compressors or two-stage energy-saving compressors, have adopted advanced technology to save power consumption, decrease carbon emissions, and increase equipment durability.

Key Benefits:

- Saved Operations Costs: With less power use, the operation costs will save a lot in power bills.

- Sustainability: Green systems facilitate businesses to adhere to environmental laws in Russia.

- Quality: Quality components of industrial grade give the guarantee of stable airflow even in heavy-duty work.

- Flexibility: It can be used in other industries such as automobile manufacturing, food industries, textiles, and building industries.

Energy-Saving Air Compressors Begin with Types

Rotary Screw Air Compressors

The mainstay of new-fangled manufacturing plants is rotary screw compressors. They have variable speed drives (VSD) that vary the speed of the motor to address the on-demand. The result of this is less energy usage and less wear on parts. These compressors suit direct use in the factories or workshops.

Two-Stage Energy-Saving Air Compressors

The two-stage system compresses the air in two stages with a lower compression ratio per stage. Benefits include:

- Less internal leakage

- Reduced heat production

- Improved efficiency and extended life of the equipment

These compressors are ideal where high-pressure air is use in many heavy-duty activities in an industry.

Oil-Free Air Compressors

Oil-free compressors have clean, contamination-free air and hence are applicable in food, pharmaceutical, and chemical industries. They integrate environmental design and power-saving technology, which decreases the operating expenses and the frequency of repair.

The Energy-Saving Compressors Semantic Benefits

Energy-efficient and Intelligent Controls

In modern compressors, smart control systems are utilized where performance and energy consumption are kept to a minimum. Automated load/unload cycles, real-time control, and temperature control ensure that the system only consumes the amount of energy required. The Russian industrial market needs this technology greatly, as energy costs may affect the profitability.

Extended Service Life, Low Maintenance

A Russian energy-efficient air compressor is durable in nature. Such components as high-strength rotors, fortified cases, and enhanced cooling options help to diminish wear and tear. This means a long service life, reduced downtime, and costs of maintenance, making it a savvy investment for industrial businesses.

Noise reduction and Safety in the workplace

Reduced decibel levels are created in many modern compressors, leading to a higher level of worker comfort and safety. Noise-reduction technology is also applicable in industries to ensure conformance with Russian standards in the workplace.

Industry-Wide Applications

Energy-efficient compressors have a wide application and cover a wide array of fields:

- Automotive Industry: Offers steady air pressure in painting, assembling, and pneumatic tools.

- Food & Beverage: Foods and beverages using oil-free compressors work to guarantee it is contaminant-free.

- Textile Industry: Supplies looms and machinery in sustained high-pressure air.

- Construction Industry: Effectively operates power tools such as jackhammers, drills, and sandblasters.

Sustainability and Cost Saving

The use of a power-saving air compressor prevents the Russian industries from:

- Cut the electricity to a tune of up to 30 percent

- Reduced CO 2 emissions and carbon footprint

- Tap Government incentives for sustainable industrial equipment

- Extend the life of equipment due to less wear and tear

To know more about the energy-saving solutions, drop by Vibrant Industrial Solutions.

The Selection of the Compressor

In choosing an air compressor with energy-saving consumption in Russia, take into consideration:

1. The Required Airflow /Pressure: Make the compressor compatible with your operations.

2. Energy Efficiency: VSD and IE3/IE4 Motor standards should be examined.

3. Maintenance and Support: Make sure that the supplier has maintenance and spare parts.

4. Environmental Compliance: Select those systems that comply with the Russian sustainability laws.

Conclusion

Energy-Saving Air Compressor in Russia is not only a device, it is an investment in efficiency and reliability, and environmental friendliness. With an appropriate selection of technology, the Russian industries can generate savings in energy, facilitating costs and high productivity throughout the operations. In Russia, with industrial-grade energy-saving compressors, investigate Vibrant solutions with customization, environmentally friendly, and high-performance air compressors.