Industrial Application of Fixed Speed Compressor in Spain: Efficiency, Reliability, and Cost-Effectiveness.

2026-01-17

The fast-changing industrial environment in Spain needs businesses with strong and reliable solutions to their compressed air requirements. A fixed speed compressor for industrial applications in Spain is one of the best choices that can be used in industrial applications in Spain. These compressors are known to perform constantly and have great mechanical reliability and low energy consumption, which has made them the staple of any industrial air system in a manufacturing company, car industry, chemical processing, or any other industry. We discuss the specifications, benefits, applications, and features of industrial fixed speed compressors, and we discuss the latest state of the art JX-300AS 400 CFM Fixed Speed Electric Air Compressor.

What is a Fixed Speed Compressor?

A fixed speed industrial compressor is a non-variable speed air compressor that is powered by an air compressor motor at a fixed, constant speed and provides a steady flow of compressed air at various demand levels. Fixed speed compressors contrast variable speed compressors, in which the motor speed is adjusted according to air consumption. A single-speed industrial compressor system is used, which is simple to design, maintain, and offers a continuous-run air compressor system efficiency.

Key advantages include:

- Consistent high-quality airflow performance.

- Industrial production facilities are highly reliable.

- Easy maintenance and reduced complexity of operation.

- Full load operation efficiency.

These compressors are ideal to be used with heavy-duty industrial machines and automated production lines where constancy in output is crucial to the process.

Fixed Speed Compressor usage in Spain

The air compressors used in industries are very popular in Spain due to their high strength and flexibility in various industries. Key applications include:

Production Facilities: Supply of compressed air through factory assembly lines and to equipment and robotics used in production.

Automobile Industry: Driving automated paint systems, pneumatic equipment, and assembly systems.

Food Processing: Making sure that the air used is clean and stable in both packaging and processing lines.

Textile Industry: Operating spinning, weaving, and knitting machines.

Chemical Plants: To provide a steady supply of air for agitating the reactors, material handling, and pneumatic valves.

Metal Fabrication: Driving cutting, welding, and material movement.

Packaging Industry: Driving high-speed filling and sealing equipment.

Cement Industry: The equipment used is heavy-duty air-powered equipment that requires a constant airflow.

JX-300AS 400 CFM Fixed Speed Electric Air Compressor

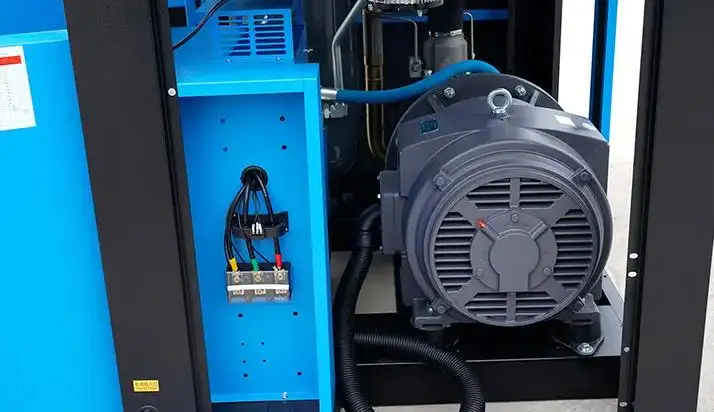

The JX-300AS is one of the most sophisticated fixed-speed industrial air compressors available in Spain, which was made with a high capacity for industrial use. The 400 CFM Fixed Speed Electric Air Compressor - JX-300AS is a fixed-speed industrial compressor that has been constructed to be stable, economical, and durable.

JX-300AS will be used in processing manufacturing sectors where it is necessary to have a high airflow delivery rate (CFM/m3/min) and constant operating pressure. Its powerful motor-driven air compressor system guarantees efficiency of mechanical drive systems, the cooling and lubrication systems guarantee that the compressor duty cycle is at optimum levels, and wear and tear are minimized.

Product Advantages

High Airflow Capacity

Having 400 CFM maximum, the JX-300AS is able to drive other pneumatic tools at the same time, improving productivity in any industrial environment.

Variable Pressure Settings

Its portable structure permits variable pressures to 0.7Mpa, 0.8Mpa, and 1.3Mpa to suit a broad range of industrial needs.

Robust Electric Motor

This compressor has a 220 kW (300 HP) motor; thus, it is highly mechanically reliable, has consistent performance, and has a long service life.

Durable Construction

It is made using industrial-grade materials that are tough to wear and tear, and thus, it can also be performed with minimal care.

Efficient Air Distribution

DN125 outlet pipe has provided a good flow of air and can be used in a wide range of industries.

Main Components

Electric Motor: Operates the system effectively

Compressor Head: It uses single permanent magnet type of machine that is optimized in terms of power and size.

Cooling System: Keeps operating temperature steady in order to be long-lasting.

Lubrication System: Lessens the amount of workload on the components, which reduces maintenance expenses and replacement of parts in the future.

Variable Speed vs Fixed Speed Compressors

In making decisions as to whether to use a fixed speed or inverter compressor, companies need to take into consideration factors such as load of operation, use of energy, and maintenance.

Fixed Speed Compressors: These are the most effective types when there are regular industrial processes and the demand for air is predictable. Compared to higher costs, less complexity, high reliability, and best suited to base-load air compressors.

Variable Speed Compressors: The motor speed is adjusted by the variable speed compressor to fit the demand, which is economical at partial load, but more complex and more expensive.

In the case of the manufacturing industry in Spain, where the use of constant-run air compressor systems is constant, the use of fixed-speed compressors in industry is preferred since the performance of the compressor is constant and does not require much maintenance.

Power Saving and Performance

The JX-300AS uses the energy-conserving technology of air compression, in which the air flow is constant, and there is minimal variation in energy. Its thermal load control also maintains constant operation and durability, hence it can be used in heavy-duty industrial equipment that is heavy-duty and in processes that run continuously.

Benefits include:

- Power consumption optimization.

- Low noise operation

- Smart air conditioning system.

- Extensive service life and low downtimes.

Industrial Applications by Industry

Manufacturing Plants

A fixed-speed rotary screw compressor provides a continuous air supply to assembly lines and automated tools.

Automotive Industry

Robotic and pneumatic equipment is supplied with reliable air in fixed-speed piston compressors that are used in the industry.

Food & Beverage

Keeps the air clean and stable, which is necessary for food safety and packaging.

Chemical & Cement Plants

Supplies stable compressed air to material handling, reactors, and heavy machinery.

Buying and Maintenance Tips

Routine Maintenance: Adhere to the recommendations of the manufacturers to maintain efficiency in the long term.

Correct Installation: Install as per the manual as a precaution for safety and performance.

Availability of Spare Parts: This is so that the compressor service network in Spain can easily supply parts.

Operational Monitoring: Measures airflow delivery rate, range of operating pressure, and power usage to ensure optimum operations.

Why is a fixed-speed compressor better to use in industry?

By selecting a fixed speed air compressor to use in industry, it is guaranteed that:

- Deterministic behavior of challenging applications.

- Low maintenance, high mechanical reliability.

- Full load energy efficiency.

- Low-cost running and extended service.

- Ability to be usable with heavy-duty industrial machinery.

These compressors are a fair trade-off between performance, cost, and sustainability to industries in Spain.

Conclusion

The piston-type compressor is the base of the fixed speed compressor for industrial applications in Spain. Through the availability of such options, such as the JX-300AS 400 CFM Fixed Speed Electric Air Compressor, the industries may obtain stable airflow, energy efficiency, and long-term productivity. Using the industrial fixed speed compressors Spain businesses are getting a cost-effective, long-lasting, and technologically advanced solution which secures excellent operation.

VIBRANT is the one to address when one needs to install or purchase fixed speed compressors in Spain and needs to get detailed technical support in buying and installing compressors with high-quality equipment that meets the demands of industries in Spain.