What Makes an Electric Motor High Performance?

- A high performance electric motor is defined by its speed, torque, and power density, which allows it to function in extreme conditions that conventional motors cannot. They are constructed to bear an immense amount of stress while maintaining a high level of energy efficiency and extending their operational lifespan by increasing efficiency.

- These electric motors are used in electric vehicles, robotics, industrial automation, and even renewable energy systems. These applications rely on precision engineering accomplished using advanced technologies that ensure peak performance. The use of these technologies helps mitigate energy consumption without comprising the motor's performance.

VIBRANT Electric Motors: Powering Innovation Across Industries

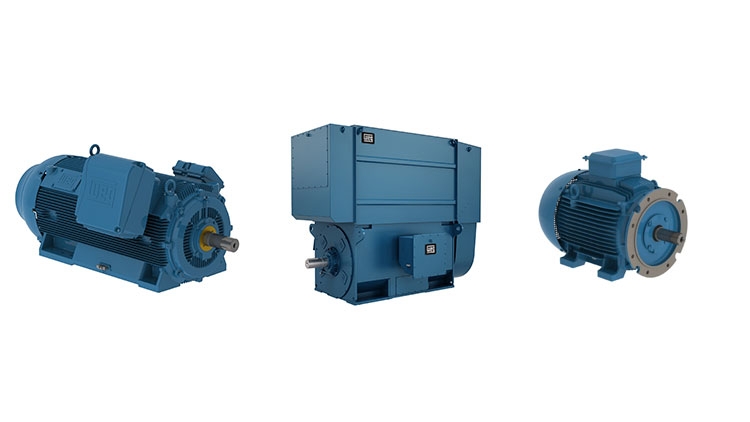

Our electric Motors are of outstanding quality, durability, reliability, and efficiency electric motors to serve diverse industries. Our designs are performance-driven as we are enabled through cutting-edge technologies that provide operational longevity under extreme conditions. Vibmac Our motors enable seamless and hassle-free operations in industrial machinery and medical devices.

Key Characteristics of Electric Motors

1. Working Efficiency

Electric motors are designed to achieve optimum operating efficiency as per industry benchmarks IE3 and IE4. Fulfilling standards set by industries helps capture expenditure through energy savings brought about with motors. The features of motors towards energy saving are directed to achieve low environmental impact and shield operational budgets.

2. Enhanced Strength and Dependability

In terms of strength, high performance electric motor is splendid. raw materials with superior performance guarantee these motors stay dependable and functionable for many years under extreme conditions with reliable, prolonged performance regardless of high temperature, dust, or moisture.

3. Changes and Customization of Products

Our selection of electric motors encompasses every sector, with our products ranging from fractional horsepower and single-phase or three-phase motors to large-scale, bespoke industrial machines. We strive to provide solutions to almost every power requirement. We also guarantee that businesses, regardless of whether they are operating small devices or large industrial machines, will find the ideal motor solution.

4. Global Service and Support

Regardless of where customers are, our global connectivity means that support is always within reach. Comprehensive service centers and customer service branches enable WEG to fulfill customers' needs on a global scale. With this network, users of motors can receive timely expert care, maintenance, and troubleshooting services, thereby reducing downtime and increasing operational efficiency.

5. Sustainability

We also undertake initiatives regarding eco-friendly practices. Several WEG electric motors are designed to use energy efficiently and have components that can be recycled. Such eco-friendly practices help companies comply with environment laws and decrease the carbon footprint of WEG’s more component solutions in sustainability efforts around the world.

Applications of High Performance Electric Motors

1. For Industrial Use

Electric Motors have a distinct purpose in the industrial setting. They power everything from Pumps and Conveyors to huge machinery. Their reliability and performance, especially while enduring strenuous tasks, make them ideal for factory use. Smooth processing is ensured with electric motors, like during WEG Electric Motor Manufacturing processes.

2. For Care Health Services

In the medical field, WEG motors are critical parts of highly accurate medical equipment and systems. Diagnostic machinery is no challenge, and even things like telemetering instrumentation call for capable WEG electric motors. They also provide enduring and dependable motors that enable proficient operation of critical healthcare systems.

3. In the Medical Services

As we know, especially in the loom as well as the textile mills serves with Spindle. WEG’s Elder line has been proven to assist clients in all these machines are of great importance in the textile industry. Therefore, the industry needs reliable electric motors to optimize energy consumption. The class of WEG’s Master Line Three-Phase Induction Motors helps capitalize on these needs while maintaining industry quality standards.

WEG Motors: Enhanced Performance Achievements

Across all sectors, WEG Motors are tailored for maximum performance. The chassis is designed to reduce air diffusion, thus improving cooling and enabling the motors to run smoothly in varied environments. In addition, simple installations, low operational complexity, and easy maintenance are possible because of the improved cable arrangement made easier by the junction box’s enlarged internal space. Furthermore, WEG Motors ensures low wear and tear under shockingly severe usage due to their rigid low low-vibration cast iron constructions, which provide high mechanical strength.

Safety beyond Efficiency with Thermal Protection Features

Thermal protection for WEG Motors comes from PTC Thermistors, which are mounted on each motor. Each motor is protected to reduce the risk of overheating and phase loss, overload, and voltage changes. WEG Motors is trusted in various industries as their operations are safe, dependable, and without interruption, making them a preferred option for critical applications.

Guidelines for Picking the Correct High-Performance Electric Motor

To ensure a high performance electric motor meets requirements, several factors should be evaluated.

1. Requirements of Application

Be sure to define what performance expectations, along with the application-defined metrics, need to be in place. Every kind of motor has specialized parts, characteristics, and capabilities designed for robotics, industrial automation, as well as for electric vehicles.

2. Power Output and Fuel Efficiency

Review the values for the power output and energy efficiency of the motor. Reduced operational cost is an added benefit with power-dense and efficient motors.

3. Motor Type

Pick the motor type appropriate to the electric vehicle’s application. For high-precision applications, a PMSM or servo motor would do great. For high-torque applications, high-torque electric motors are more applicable.

4. Durability and Maintenance

Select electric motors with minimal maintenance and long useful life. This reliability is further improved with some motor designs that add advanced motor features, along with sensorless control systems.

Conclusion

Modern-day high-performance electric motors are revolutionizing technology. It doesn’t matter if you’re dealing with electric vehicles, robotics, industrial automation, or even the aerospace industry; a basic understanding of the technologies revolving around electric motors will keep you ahead in the race. Due to their unmatched efficiency, power density, and precision, these motors are bound to be the center of development in harsh applications. VIBRANT specializes in high-performance motor design and development for demanding industry applications.