An industrial belt driven air compressor in Brazil is a motor-powered belt air compressor that was created to work continuously in the industries. Belt-driven systems have a belt and pulley system that transfers power between the motor and the compressor pump, as opposed to the direct-drive compressor. This gives it flexibility in speed and torque, less noise generation, and increased durability, which makes it applicable in heavy-duty air compression solutions.

The Belt-Driven Compressors are characterized by the following features:

- Constant and uninterrupted supply of air to the tools and machinery used in industries.

- Silent operation since the belt-driven system.

- Less wear and tear as opposed to direct drives.

- Low energy usage performance even with long-run operations.

The manufacturing plants, automotive workshops, chemical processing units, textile factories, and other industries in Brazil use industrial air compressors, which have a belt drive to ensure a continuous flow of production.

Carbon Belt Driven Air Compressor in Brazil: Strong, Good, and Reliable

- The dynamic industrial industry of Brazil needs reliable air compression solutions that are efficient and intensive in use. The Brazil industrial belt driven air compressor is the perfect product for factories, manufacturing plants, car workshops, food processing plants, etc. The compressors are known to operate silently, have consistent airflow, and last long, and therefore your industrial processes will continue without a hitch.

- The B-X15A belt drive air compressor is one of the most sophisticated and compact belt drive compressors available, a machine that offers power, flexibility, and efficiency in a robust but small machine. This article discusses industrial belt-driven compressors, their features, uses, technical characteristics, advantages, and why they will be the preferred choice when Brazilians industries need to use them.

Industrial Belt Driven Air Compressor Usages in Brazil

Industrial belt driven air compressor in Brazil are multipurpose and suitable for various industries:

- Manufacturing Plants

Manufacturing plants will use belt-driven compressors that supply steady air to pneumatic tools, assembly lines, and automated production. Their all-time running belt-driven compressor design makes sure that productivity is not fluctuated with the change in pressure.

- Automotive Industry

Automotive industry automotive applications of industrial air compressors are used in spray painting, automotive booths, tire inflation systems, and pneumatic assembly tools. The belt-driven design will reduce noise, which helps make workshops comfortable for the employees.

- Food Processing

Compressed air is clean and reliable in the food processing industry, thanks to the belt-driven compressor, which is why it is of significance in packaging, filling, and even in bottling. A belt compressor operates on a motor to maintain the right airflow in accordance with hygienic and operational standards.

- Textile Industry

Belt-driven compressors used in the textile industry are used to supply constant compressed air to the weaving, knitting, and sewing machines so that they can operate smoothly without a variation in pressure that might impair quality.

- Chemical and Cement Plants

These sectors require air compression solutions that are high-duty to agitate the reactor, transport materials, and pneumatic purposes. The reason why continuous-duty types of compressors, which are belt-driven, are ideal is because of their tough mechanical drive system and reliability.

- Metal Fabrication and Packaging

In metal fabrication, belt-driven compressors and packaging industry air compressors, steady pressure is important in cutting, welding, and automated packaging systems. Belt-driven compressors are the ones that offer the required airflow with minimum downtime.

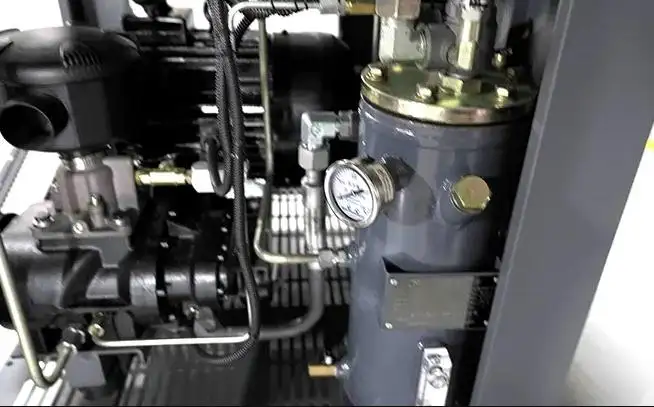

Launching B-X15A Belt-Drive Air Compressor

- The B-X15A is a power-reliable compact compressor in one of the industrial belt-driven compressors in Brazil. The intensive manufacturing conditions, such as garages to manufacturing plants, are ideal with this model, as it offers consistent performance and low noise because it is a belt-driven system.

- The B-X15A has a high performance of 0.8 MPa pressure and airflow of 1.5 m3/min to ensure that all tools and machinery will operate sustainably. The small size (14-1/2 W x 8-1/2 D x 7-1/2 H) of the product makes it simple to install it into any workspace and provides flexibility and mobility.

Product Features

Powerful Motor: The 11 kW (15 HP) motor ensures consistent and reliable airflow in the industry.

- Small and Strong Construction: It is small in size and yet robust enough to be installed easily and still last long when used frequently by businesses.

- Reliable Air Delivery: Is 1.5 m3/min at 0.8 MPa, which ensures that the tools and machinery can run efficiently.

- Less Noise: The belt drive system is noisier, and it will provide a more comfortable working environment.

- Flexible Power Options: The voltage can be set to 110 V to 480 V to make it appropriate to any industrial environment.

- User-friendly Connection: The pipe wear is G3/4 in diameter, which can easily connect with the existing industrial systems.

Primary Components and Wear Parts

- Motor: 11 kW high-performance motor to operate continuously.

- Compressor Head: Have Belts to maintain constant air compression.

- Filters and Belts: They should be serviced regularly to achieve high efficiency.

- Seals and O-Rings: Pressure and leakage prevention.

- Air Filters: This guarantees effective air discharge that is clean.

Safety and Hygiene

- Good ventilation: Do not allow overheating by ensuring that air moves about the unit.

- Periodic Servicing: Check belts, filters, and seals to enable efficient working.

- Voltage Compatibility: Do not use with a voltage that is not correct or may cause damage.

- Air Leak Checks: Fixed output pressure checks are made regularly.

- Keep It Clean: Cleaning will help to increase service life and decrease maintenance problems.

Belt-Driven Compressors Technical Advantages

Belt-driven compressors offer the following important advantages compared to other air compressors in the industry:

- Plug-and- play Power Transmission: The belt drive enables adjustment of speed and torque, which is not possible with direct-drive compressors.

- Reduced Noise Level: Fits well in workshops and factories, and causes minimal disturbance.

- Less Maintenance: Belts will absorb vibrations, and this will lessen the pressure on mechanical parts.

- Energy-Efficient Operation: Motor efficiency is optimized, and air flow is steady, thereby minimizing power usage.

- Long-lasting and Stable: It fits long-run operations of industrial compressors.

Performance, Efficiency, and Sustainability

- Energy-Efficient Industrial Air System: Lowers operation expenses.

- Constant Airflow Performance: Keeps the pressure of the industrial air at the same level.

- Low-Maintenance Belt-Driven Compressor: Fewer repairs and extended life.

- Sustainable Operations: Supply Chain: It is compatible with energy management systems and industrial compliance standards.

Conclusion

The industrial belt driven air compressor in Brazil is a superior product that every business would want to have due to reliability, performance, and energy savings. The B-X15A belt drive compressor, used in manufacturing facilities and automotive workshops, is able to operate continuously, without fluctuation, and quietly, with zero disturbance to the needs of the high-volume industrial set-up. VIBRANT offers more information about industrial air compressors in Brazil and be sure to receive your high-performance belt-driven compressor today.