Belt Drive Air Compressor for Trucks: Enhancing Your Route with Dependability and Skill

A reliable source of power greatly impacts operational efficiency in the world of trucks. The Industrial Belt Driven Air Compressor for trucks is truly versatile, designed to endure and work in high-performance environments. From tool usage to inflating tires, these air compressors demonstrate exceptional performance and durability.

What is a Belt Drive Air Compressor for Trucks?

A belt drive air compressor is a type of air compressor that makes use of a belt-driven power mechanism. Automobile compressors offer better transmission efficiency, while operating at lower vibrations and noise levels. For those who require portable on-the-go air compression, it serves a range of tasks, as it is attached to the truck’s engine.

Key Features of Belt Drive Air Compressors

– Exceptional Efficiency: The unrivaled efficiency of these compressors stems from the belt-driven system while achieving maximum performance level. This serves air demanding power surroundings, ranging from construction sites and workshops, and beyond.

• Easy Installation: Its compact nature allows it to be installed onto the truck with ease. Its lightweight air compressor, which is multifunctional, can be stored in tight spaces, thus making it appropriate for several trucks.

• Low Operational Noise: Distinguished from its competitors, its low noise level. The Belt Drive Air Compressor allows for greater portability to low noise areas, Low noise output makes it easier for workers to concentrate on their tasks instead of worrying about distractions.

Applications of Belt Drive Air Compressors in the Trucking Sector

Almost every field makes use of belt-drive air compressors, including:

– Construction: Construction workers need an air supply in the form of a belt drive compressor for power tools and for inflating and deflating vehicle tires.

– Furniture and Woodworking: To maintain precision in furniture manufacturing, power tools like routers, drills, and sanders that are used for woodworking need to be supplied with compressed air.

– Printing and Packaging: Compressed air is used in operating printing machines and maintaining the operation of packaging machines.

Specific Factors That Make Belt Drive Air Compressors Superior to Others?

– Greater Reliability: With proper maintenance, users can expect a long service life of the belt drive air compressor. While its workload is intense, the compressor can still outperform its expectations. It has a tough working environment, a capable multi-layer belt system that permits the machine to run for long periods without failure.

– Varied Models – Industries are catered for at different levels, with belt drive compressors coming in different sizes and capacity models. No matter if you are looking for a 4.5 kW compressor or a 15 kW compressor, there is always a belt drive air compressor to serve you.

– Secure and Reliable Operation – The four corner design features guarantee that the machine will remain stationary and not move, shake, or vibrate. These qualities make the compressor best suited for more advanced settings where stability stands as a prerequisite.

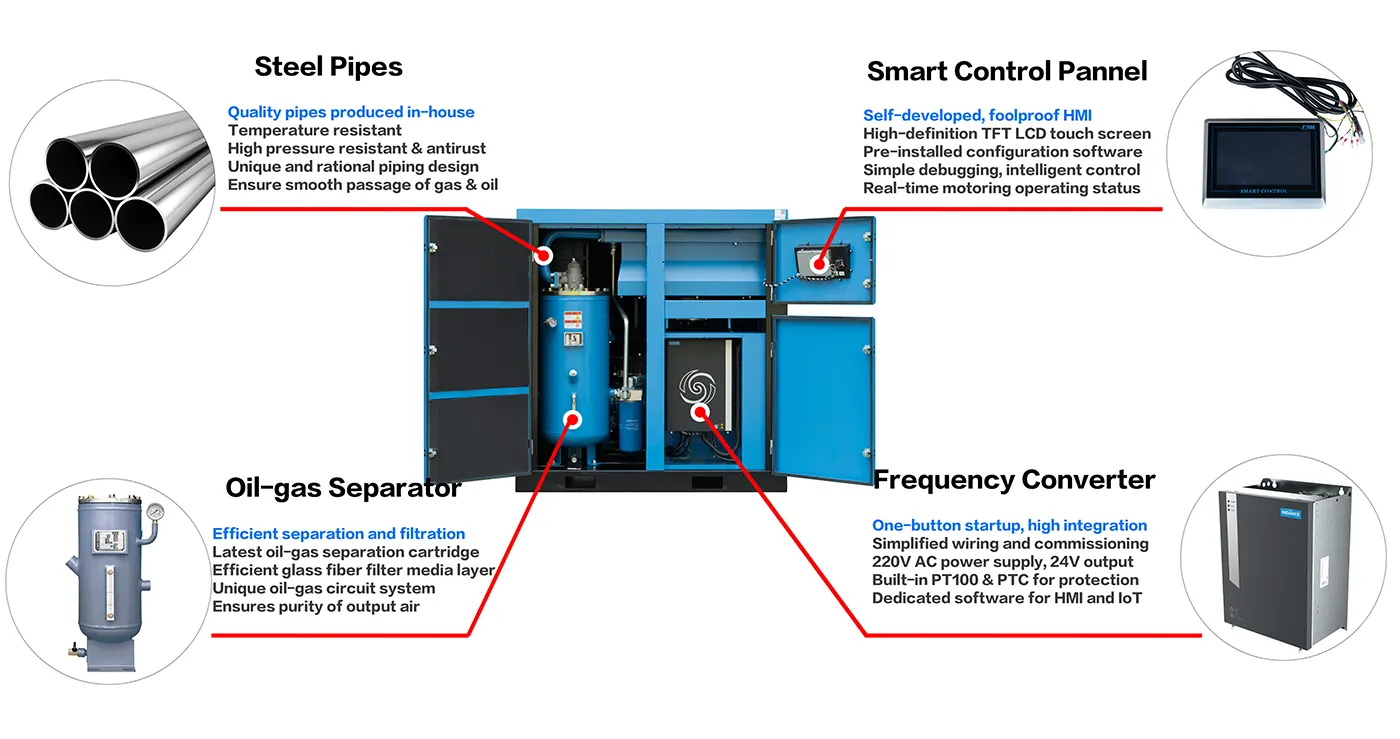

Crucial Components of a Belt-Driven Air Compressor

To make the best choice of a belt driven air compressor, one needs to know some of its basic components, such as:

– Motor – The most widely used source of power for compressors is an electric motor. Some units, however, can be powered with gasoline or dies; for instance, portable units.

– Pulley and Belt: These components operate together as the powering device of the motor, driving the compressor pump with the aid of the belt and pulley system.

– Compressor Pump – This system is made up of components such as a piston (in piston air compressor) or a screw (in rotary screw compressors) which provide the mechanism for compressing air.

– Tank: This is a container that stores compressed air and helps in maintaining a constant supply during the processes involved.

Cooling System: A cooling system is built into the unit’s belt-driven compressors to mitigate the overheating during operation.

Benefits of Industrial Belt Driven Air Compressors

Direct-drive units heat far more rapidly and do not work nearly as well as belt-driven compressors. These come with several advantages, as mentioned below:

Reliability

Air belt-driven compressors operate reliably well as their motor spins at a slower RPM. This leads to less wear and tear and longer operating life, which leads to the overall system enduring stress and demand productivity with ease.

Durability

With consistent proper maintenance, the long-term value of well-maintained air compressors gives significant savings by reducing maintenance costs while enhancing performance during periods of high demand.

Cost-Effectiveness

Direct-drive air belt units suffer from being outperformed by these belt-driven compressors. While new direct-drive models might be sleek, these units offer better value and perform far better with proactive maintenance.

Flexibility

Due to belt speeds, these systems can be tailored to machine needs, making them adaptable and useful for various industries.

Simple Upkeep

The other systems were simplified by the use of belt driven compressors, which improved the mechanical maintenance of the equipment. Simple regular checking of the key belts and oil level will allow these systems to operate for many years uninterrupted.

Tips to Ensure Sustained Performance Maintenance

To help ensure your compressor operates to and beyond expectations for a long period, here are some additional tips regarding your industrial belt driven air compressor:

1. Clean Parts: Buildup of dirt and other debris should be properly cleaned from all components of an air compressor to ensure smooth operations.

2. Inspect Parts: Bores and other areas of the air compressor are susceptible to wearing out over time. Make sure they are operating at nominal conditions, as well as checking the rotation and drives dynamically.

3. Pump Oil: Make sure lubricated compressors have the proper amount of lubricants in the free flowing hinges.

4. Change Air Filters: Replace air filters regularly as they can accumulate dirt, which can harm filter productivity.

5. Dome Pressure: Make sure seals surrounding hoses, fittings, and others do not trap air as compressibility ratios go down and making everything less efficient.

6. Check Operating Pressure: Set up and ensure the optimum with gauge pressures that do not exceed the normal PSI levels.

Conclusion

An Industrial Belt Driven Air Compressor is highly useful to such Industries which require high dependability, sustained workflows, and enduring agility in efficient, durable performance. In addition, the dual benefit of cost effectiveness and system longevity makes it a tactical purchase for industrial operations. VIBRANT offers an extensive range of industrial air compressors to suit different applications and business needs. Visit us today and let us assist you in selecting the ideal air compressor that fits your needs.