CompressorsThe energy efficiency, operational accuracy, and system reliability are especially important in the present-day competitive environment in the industrial world. The industrial VFD air compressor in UK is among the technological changes that have brought about this transformation in the face of businesses interested in minimizing costs, maximizing productivity, and minimizing environmental impact.

Variable Frequency Drive (VFD) air compressors, or variable speed drive (VSD) air compressors, are variable speed air compressors that automatically vary the motor speed based on the demand, so that only the necessary quantities of air are produced. This qualifies them as the best fit in those industries within the UK that are looking at optimized compressed air solutions, and do not waste power

Learning the Industrial VFD Air Compressors

A Variable Frequency Drive (VFD) is an electronic device that regulates the speed of the motor, changing the frequency and voltage fed to the motor. When added to an industrial air compressor, it can be operated under variable speed, that is, it can only be operated as fast as it must be: no faster, no slower.

How It Works

Under the traditional fixed speed compressors, the motor operates constantly at full capacity, irrespective of the air demand. US industrial air compressors, however, are controlled by VFDs that detect changes in air demand and automatically adjust the motor RPM to keep it constant.

This technology leads to:

- Reduced energy consumption

- Less mechanical stress

- Long service life of equipment.

- Stable system pressure

The Reason behind the migration of UK Industries to VFD Air Compressors

In the UK, the automotive, food processing, pharmaceutical, and heavy manufacturing industries are shifting toward VFD industrial air compressors as energy costs and sustainability requirements continue to rise.

The major causes of this shift include:

- Electricity prices go up, and businesses find the need to get a solution that is energy-efficient.

- Government programs encourage a decrease in carbon footprint.

- Variable frequency drive screw air compressors UK, which are technologically advanced to enhance ROI.

- Small-sized styles, which can be placed in small industrial areas.

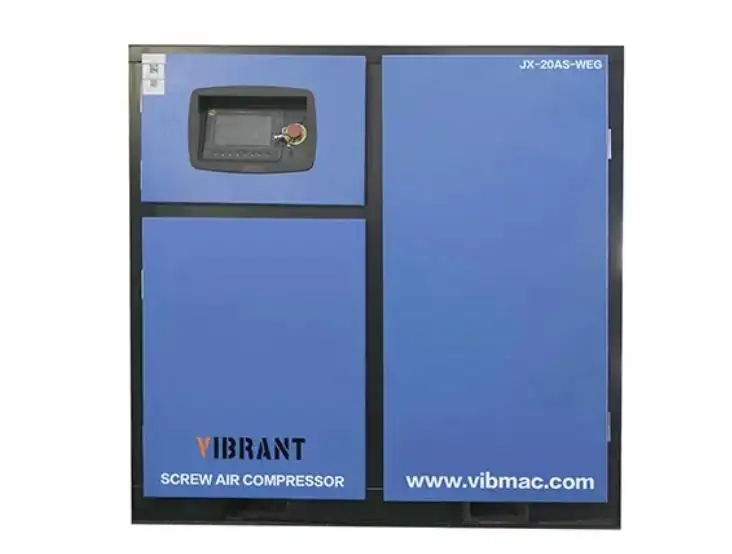

Characteristics of JX-20AS-WEG VFD Air Compressor

VFD Technology

The main component of this compressor is its variable frequency drive system that enables the motor to be controlled in real-time. This screw compressor VFD drive system in the UK will be used to ensure maximum use of energy and prevent the waste of power.

High Performance

Its pressure of 0.8-1.3 MPa serves the entire scope of industrial needs - automotive production lines to chemical production facilities.

Efficient FAD Delivery

The flow rate of 2.3 m3/min at 0.8 MPa and 1.7 m3/min at 1.3 MPa makes the process steady under the conditions of different loads.

Compact Design

Small footprint (1350mm x 850mm x 1110mm) and easy weight of 430 kg for installation make it easy to use in restricted industrial installations.

Low Noise Operation

This compressor is working at a sound level of [?]65 dB, which is very quiet and comfortable to work in marijuana, particularly in the field of precision manufacturing and laboratory work.

Standard Pipe Connectivity

The JX-20AS-WEG has a G1 pipe diameter and therefore can easily fit into the various air distribution systems.

Primary Elements and Operating Systems

Compressor Unit

The main principle of the compressor is the effective conversion of electrical energy into pressurized air with the best load-to-output balance.

VFD Drive System

The industrial air compressor with VFD control in the United Kingdom is one that provides accurate adjustment of the motor speed, thereby minimizing wastes of energy and mechanical strain, thereby extending the life of the motor.

Cooling System

The cooling system has been designed to maintain the usual functioning of the compressor at the optimal temperatures even when working in continuous cycles.

Lubrication System

The automatic lubrication system ensures that the inside functions smoothly and reduces the friction and wear of the parts.

WEG Motor

This compressor has a 100 HP WEG motor that is robust yet highly mechanically efficient, and ensures that the equipment will last long and produce a steady torque.

Energy Efficiency: The Basic Benefit

A VFD air compressor UK has the capability of saving 35-50 percent of power usage as compared to fixed-speed air compressor models. This makes it among the energy-efficient industrial compressor systems in the UK.

Advantages of Energy Efficiency:

- Lower operating costs

- Reduced CO2 emissions

- Reduced wear and tear of components.

- Improved motor efficiency

- Adherence to energy laws in the UK.

The energy-saving industrial VFD air compressor UK is aimed at companies striving to reconcile between productivity and sustainability, which is the main objective of contemporary industrial management.

Installation and maintenance

Easy Installation

In the UK, the installation of a VFD air compressor is easy, and this can be attributed to its small size and conventional fittings. A professional installation team in Vibmac is used to provide smooth installation and calibration of the system.

Maintenance Simplicity

It is easier to perform routine maintenance as it simplifies:

- Availability of component design.

- Combined diagnosis system.

- Anticipatory maintenance notifications.

The industrial air compressor VFD UK has smart control panels that alert the operators about any anomalies in operation, and this eliminates downtimes.

Applications in the UK Industries

Variable frequency drive air compressor UK is applicable in:

- Automobile manufacturing

- Textile processing

- Medical and pharmaceutical.

- Food and beverage manufacturing.

- Aerospace engineering

- Metal fabrication

VDF-driven compressors also result in quality products through real-time control of airflow, providing every process with the precise amount of air pressure it requires, thereby lowering the cost of energy.

Merits of Industrial VFD Air Compressors

Optimized Energy Use: Motor speed is automatically changed to meet air demand.

Less Start-Up Current: Premeditated launches ensure electrical impulses.

Reduced Noise Level: Suited to indoor centers.

Increased Life expectancy: Reduced mechanical wear and heating.

Constant Air Pressure: Eliminates system inefficiencies.

Better Return on Investment (ROI): Energy savings easily recoup the initial cost in a very short time.

Optimization of Compressed-Air System in the UK Industry

A VFD UK system in the form of compressed air can radically streamline the operations of the plant by balancing demand, minimizing leakages, and minimizing the output of carbon.

Our industrial air compressor with a VFD motor UK line is the invention of advanced engineering technologies to enable industries to obtain the aspect of ISO 50001 energy management compliance and sustainability certification.

Conclusion:

The industrial VFD air compressor in UK is not merely a technological innovation but a move towards a strategic investment that a business that wants to remain ahead in the efficiency, sustainability, and performance of its business.

Models such as JX-20AS-WEG are leading innovative standards in the industry of air management through their smart VFD control system, energy-saving performance, and, finally, their compact design. You can be in manufacturing or engineering, production, it does not matter; the thing is to integrate a VFD-controlled air compressor and a smarter and more profitable future.