PM VSD Screw Air Compressor: The Best Low Noise Screw Air Compressor in Russia

2025-07-30

- PM VSD screw compressors have made a name for themselves for their remarkable efficiency and low noise operation. The PM VSD screw compressor provides low noise, highly efficient compressed air solutions. It has PM PR synchronous Motors with PMSM technology and a VSD that guarantees great noise reduction.

- More importantly, PM VSD screws have control of their cubic feet per minute. The latter is very important in low-noise operations of textile, medical, and other industrial sectors. PM VSD screw compressors have VSD controllers as add-ons. These Low Noise Screw Air Compressor in Russia are modern in terms of control of energy efficiency, precision control, silence, and operation, which are vital for industrial, textile, and medical sectors.

PM Technology: high efficiency takes charming features for its devices to the next level

The synchronous motors paired with PM increase efficiency by 3-5% compared to traditional motors, which is a wonderful advantage. These advantages are most helpful because they are permanent and provided throughout the entire operating range. At low speeds, the compressor's low fuel consumption enables it to keep operating, which is a wonderful advantage. Regardless of whether your facility works continuously or intermittently, this compressor modifies its speed and airflow to meet the demand, thereby conserving energy. This adaptability is valuable for businesses that have fluctuating workloads.

- The Increased Ease of Maintenance

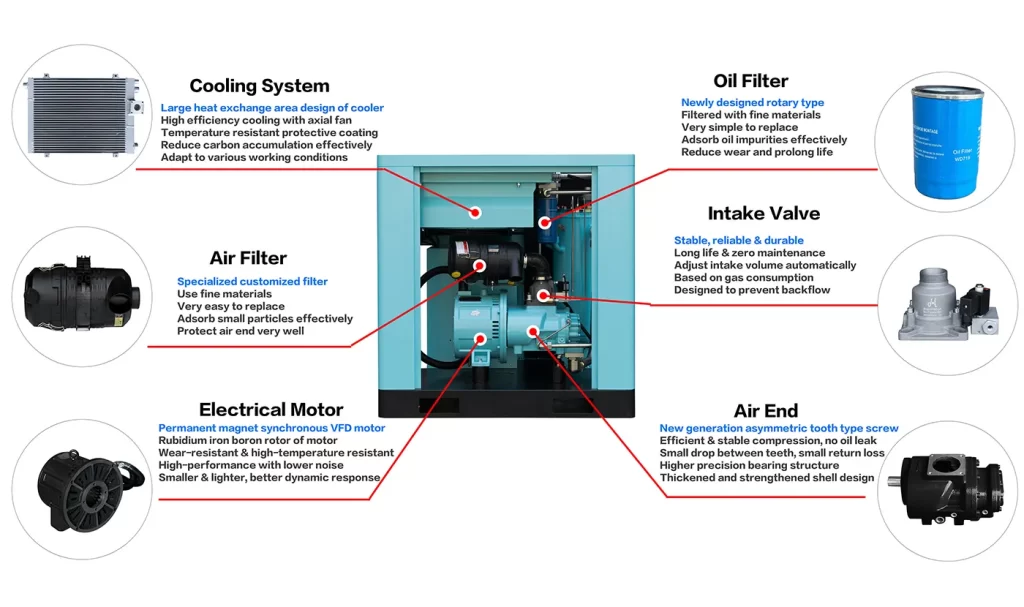

Air compressors are typically associated with high maintenance and upkeep costs. These costs are significantly reduced with the PM VSD Screw Air Compressor as it is easier to maintain and its upkeep is quicker. It has fewer consumable parts and, as a result, there are fewer breakdowns. The maintenance required is minimal, and any malfunctions can be remedied quickly. Due to these features, this kind of compressor is perfect for shops and plants since maintenance and servicing are greatly minimized.

The VSD Screw Air Compressor PM is a State-of-the-Art Industrial machine

The PM VSD Screw Air Compressor is a perfect fit for an industrial workplace since the safety features are sophisticated. The unit has safety PTC temperature sensors that monitor the system's heat and will shut down the machine if the heat is too high. This protective approach is preventive of overheating the compressor, the motor, and any other components that are permitted to run with uninterrupted air flow. These features make the PM VSD compressor suitable for places with high heat or sensitive equipment that require a high level of protection.

- Almost Silent Operation

Due to the use of low-vibration materials and precise engineering, this compressor model is quieter than its traditional counterparts. It is suitable for workshops, hospitals, and textile factories as it provides quieter environments. This model is equipped with a smooth start system, which in turn relaxes mechanical strain as well as the pull to the system during start-up. This results in smoother operation, which cuts down wear and tear on the system. Eco-friendly businesses focused on the reduction of environmental noise will find this model appealing.

- No Loss of Oil Guarantee and Clear Emissions

Every model contains a first-rate air end, developed in Germany, to guarantee the compressor's reliability and no oil leakage. This characteristic is a game changer in clean air-sensitive industries, especially in medical, food processing, and textile industries. This model is confident to exceed the industry benchmark due to its micro oil-injection technology. It also strengthens the quality of the compressed air, which offers extra assurance in sensitive environments.

- Smart Function and Monitoring with Real-Time data

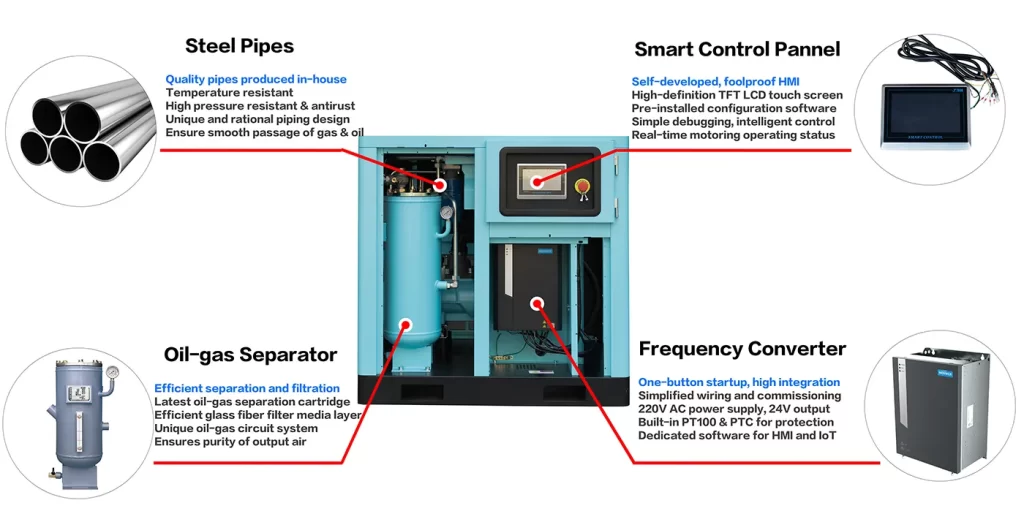

Via the adept digital controller, the PM VSD Screw Air Compressor model digitally captures more than twenty critical parameters and calibrates them in real-time and stores the data. It also performs notification and PM scheduling, as well as monitoring energy use per specified time. Analytical evaluation adds precision, which strengthens inter-departmental productivity. Also, the system's operating lifespan is augmented while the likelihood of unforeseen malfunctioning diminishes.

Suitable For Several Sectors In Russia

The PM VSD Screw Air Compressor is already a preferred choice across numerous industries:

- INDUSTRIAL APPLICATIONS – Air compressors for factories and industrial operations.

- MEDICAL INDUSTRY – Supplies purified and properly conditioned air for instruments and clinical as well as laboratory apparatus. She is taking care of the silence and the air purity for sensitive machines.

- TEXTILES INDUSTRY – Air precision in textiles grooming guarantees air fidelity precision.

These air compressors enhance productivity and efficiency in workshops and factories, which in turn helps in fuel costs. It is fuel-efficient and also quieter. It is reliable and helps improve productivity.

Reasons To Pick a Screw Air Compressor with Low Noise

- Looking for a low noise screw air compressor in Russia? VIBMAC’s PM VSD Screw Air Compressor is highly recommended as it is a well-known low maintenance and energy-efficient solution. The PM VSDV series is a low-noise, air precision screw compressor designed for low maintenance and energy efficiency. Professionals across the country are using it for the high-technology solution and precision it offers.

- Workshop owners and manufacturers are burdened with the duty of maintaining noise levels at a low threshold that is comfortable and safe for people. Low-noise screw air compressor helps the workplace productivity as well as comfort. Low-noise screw air compressors are designed to provide efficiency and high reliability.

Maintenance & Lifecycle Costs: Maintenance-Down-Time-Money Efficient Strategies

The casing around the air compressors manufactured by Vendor is made specifically to ensure the compressor is as quiet and durable as possible. The less tailored maintenance is performed, the lower overall product lifecycle costing becomes, and maintenance becomes easier for the valuable investments put down.

- Low-Maintenance Features

Low Maintenance Features Include: Oil Separators: Reduce maintenance costs and time with infrequent servicing without compromising on necessary upkeep.

- Self–Cleaning Air Filters – Reduce Dynamic Airflow Blockages caused by Filters and Cleaning.

- Real-Time Diagnostics – Enhance Efficiency through Correction of Irregularities and Automated Self-Correction.

- Remote IoT Monitoring (select models) – Provides Alerts, Insights, and Performance Data Remotely.

Along with better protection against harsh operating conditions, these compressors are equipped with better wear-resistant components and materials. Preservation of critical components is aided by reduced vibration and friction, along with better performance.

VIBMAC's quiet compressors improve servicing from a frequency, cost, and time perspective. The lifecycle value is outstanding. These compressors are ideal for industrial users in Russia. The total cost of ownership is also greatly improved, from energy expenses to maintenance ease.

Conclusion

In the case of a Low Noise Screw Air Compressor in Russia selection, this is certainly not just a product selection in Russia. It is a significant consideration in crew health and wellbeing, the company's energy costs, and regulatory compliance. VIBRANT compressors, which are rugged, affordable, and quiet, support the diverse needs of Russian industries from small workshops to factories.