Oil Free Air Compressor

100% Oil-Free Air: Expels from the air a chemical which to create good produce takes and purifies it.

Energy-Efficient Motor: Since energy is reduced, it means that the cost of operations in an entity or establishment is cut down.

Quiet Operation: Operates at a slow rate and therefore may be utilized wherever minimal disruption is desired.

Compact Design: Long-wearing, stable in size, easily accessible elements and that is all they require is, more or less, no care at all.

Adopting self-developed head, high-efficiency motor and independent heat dissipation system to ensure long maintenance cycle, low maintenance requirement, low operating sound and smooth operation.

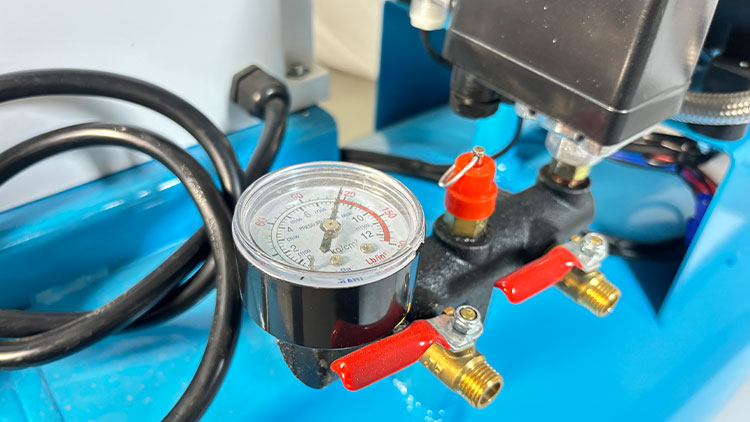

Few moving parts, simple and solid structure, high safety, easy to operate, 100% oil-free crankcase technology, providing clean compressed air, independent casting cylinders, maintenance is more convenient.

Low energy consumption, small loss, lubricant saving, reliable operation over 8000 ~ 10000h; unique structure, long maintenance cycle, long service life.