Adsorption dryer

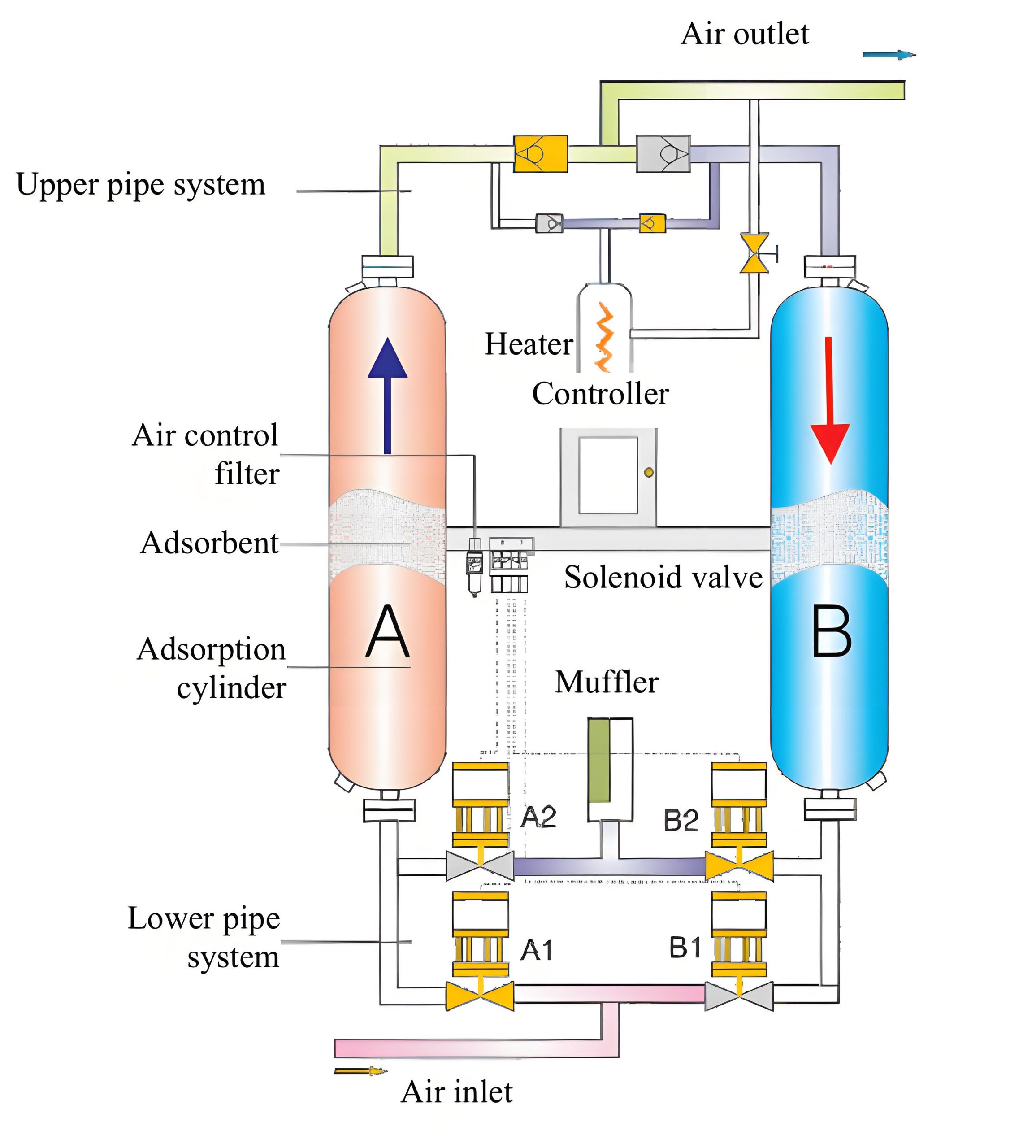

Adsorption dryers are widely used in industrial fields as compressed air drying equipment. They effectively remove moisture from compressed air through the physical adsorption of adsorbents, providing dry and clean air for various processes.

Adsorption Air Dryer

Adsorption-type air dryers are widely used in industrial fields as air drying equipment. They effectively remove moisture from compressed air through the physical adsorption action of adsorbents, providing dry and clean air for various production processes.

Adsorption dryer

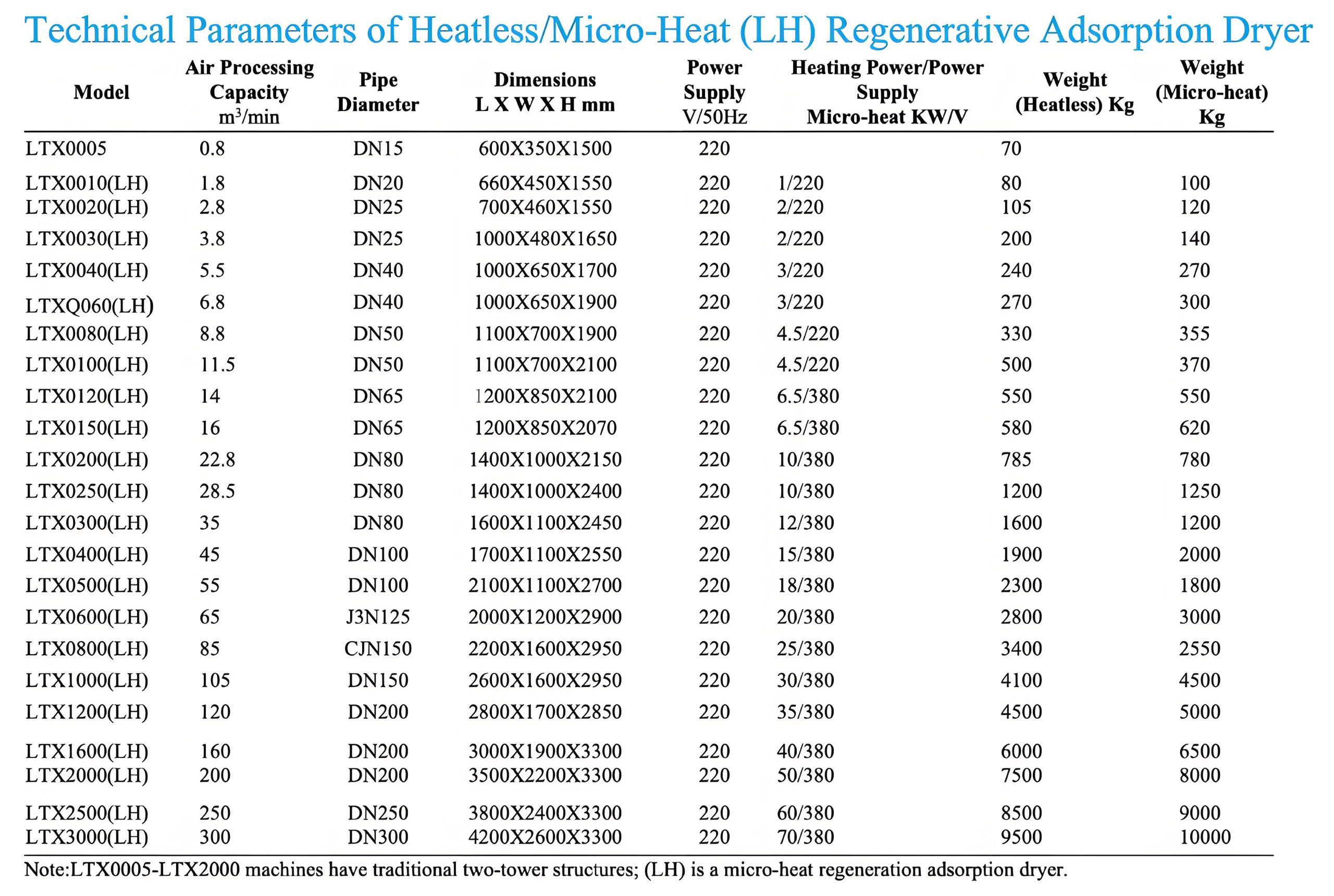

- Air Processing Capacity(m³/min): 0.8~300

- Power Supply: 380V/50Hz,According to customer customization

- Dimensions(mm): 600X350X1500~4200X2600X3300

- Weight(kg): 70~10000

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now