touch screen

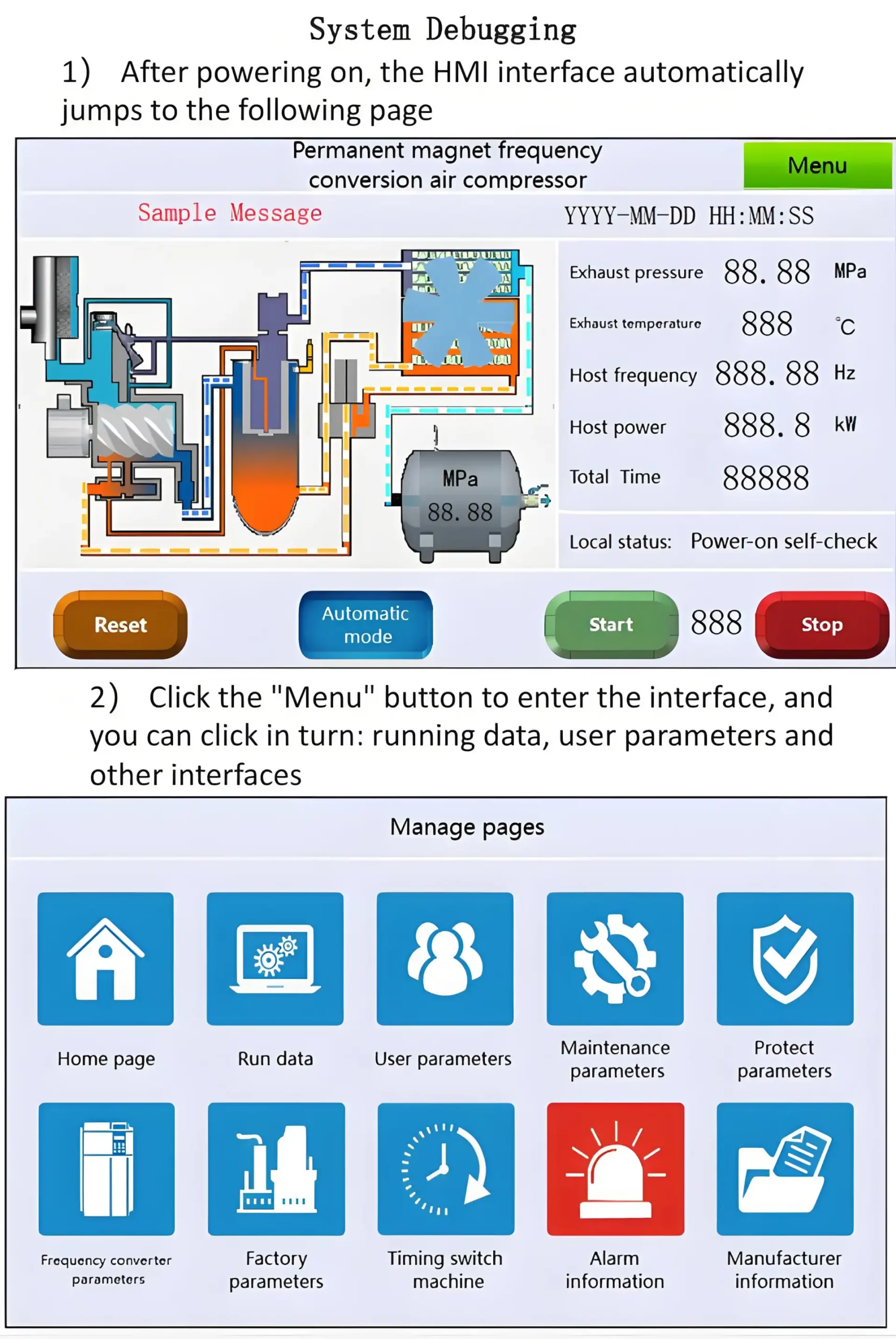

The air compressor control panel is an indispensable intelligent control core in modern air compressor systems. It integrates a variety of functions, enabling efficient monitoring, precise control, and intelligent management of the air compressor. A good control interaction system can promote harmonious human-machine interaction.

Air compressor control panel

As an important component of the air compressor system, the air compressor control panel boasts powerful functions, distinct advantages, simple operation and a reasonable structure. It can effectively improve the operating efficiency and management level of the air compressor, and ensure the safe and stable operation of the equipment. With functions such as real-time monitoring, intelligent control, fault diagnosis and data recording, the control panel provides users with an efficient, reliable and energy-saving operation and management platform for the air compressor, and is an indispensable key device in modern air compressor systems.

Control Panel

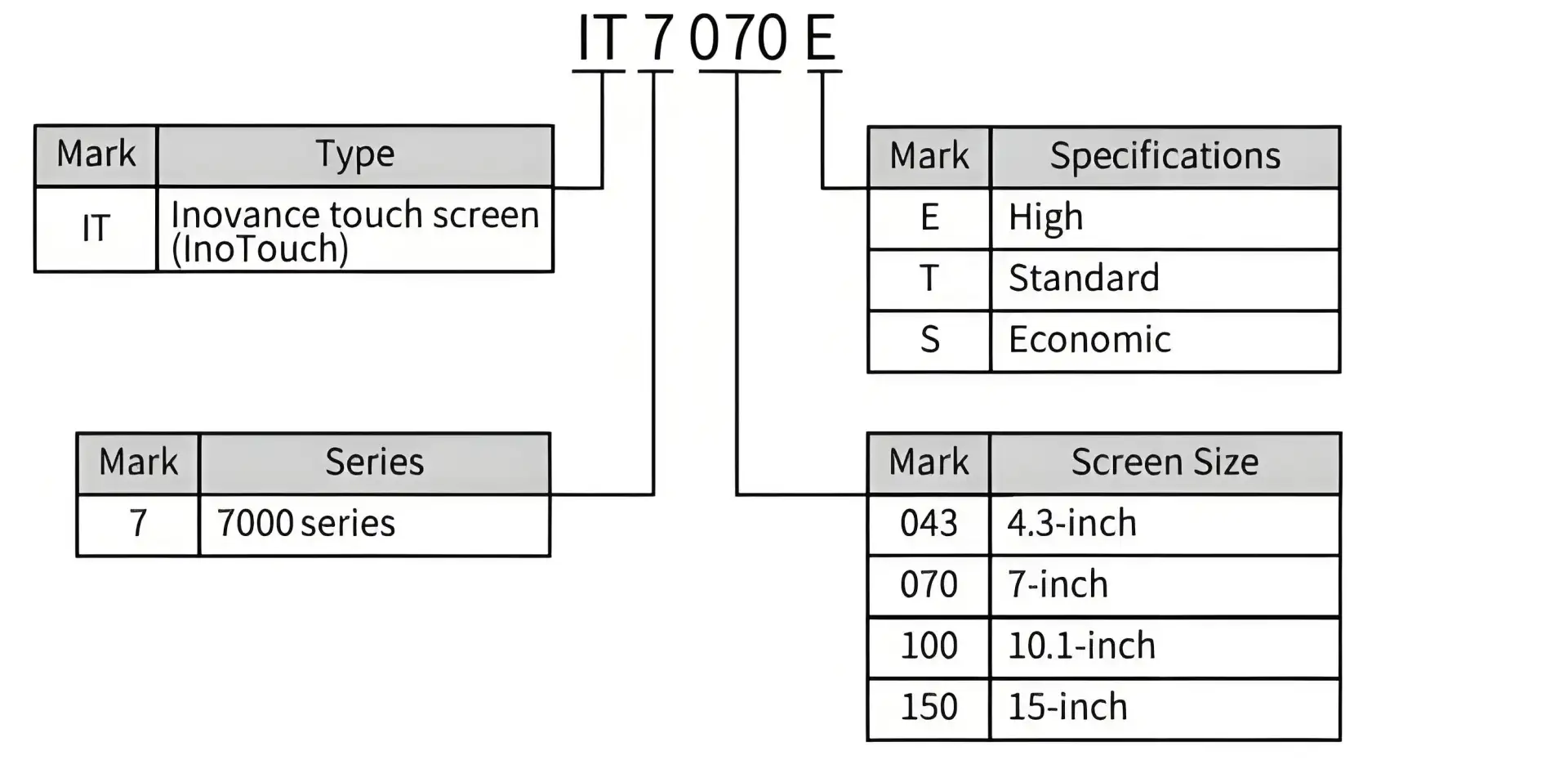

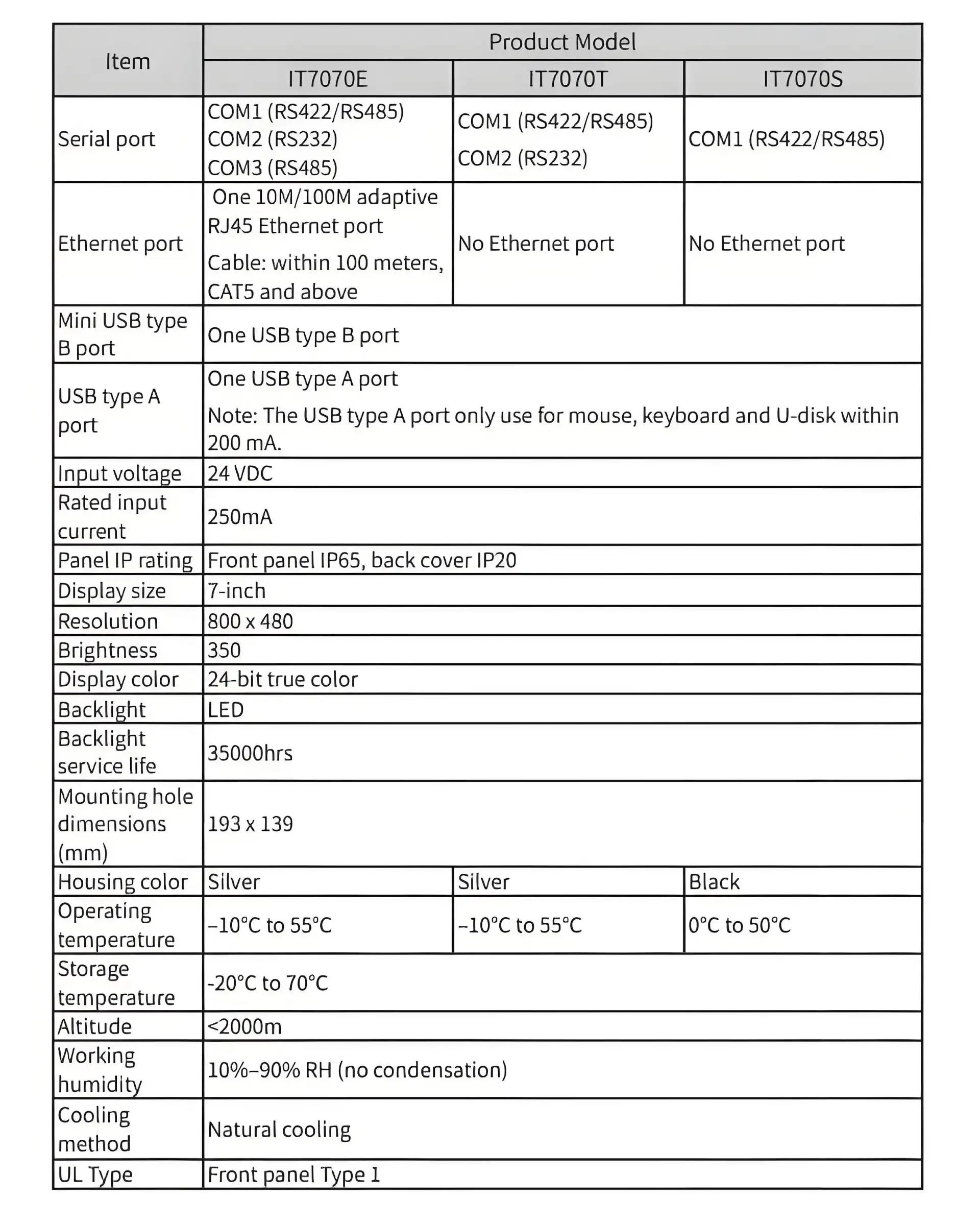

- Brand: Inovance/Plot

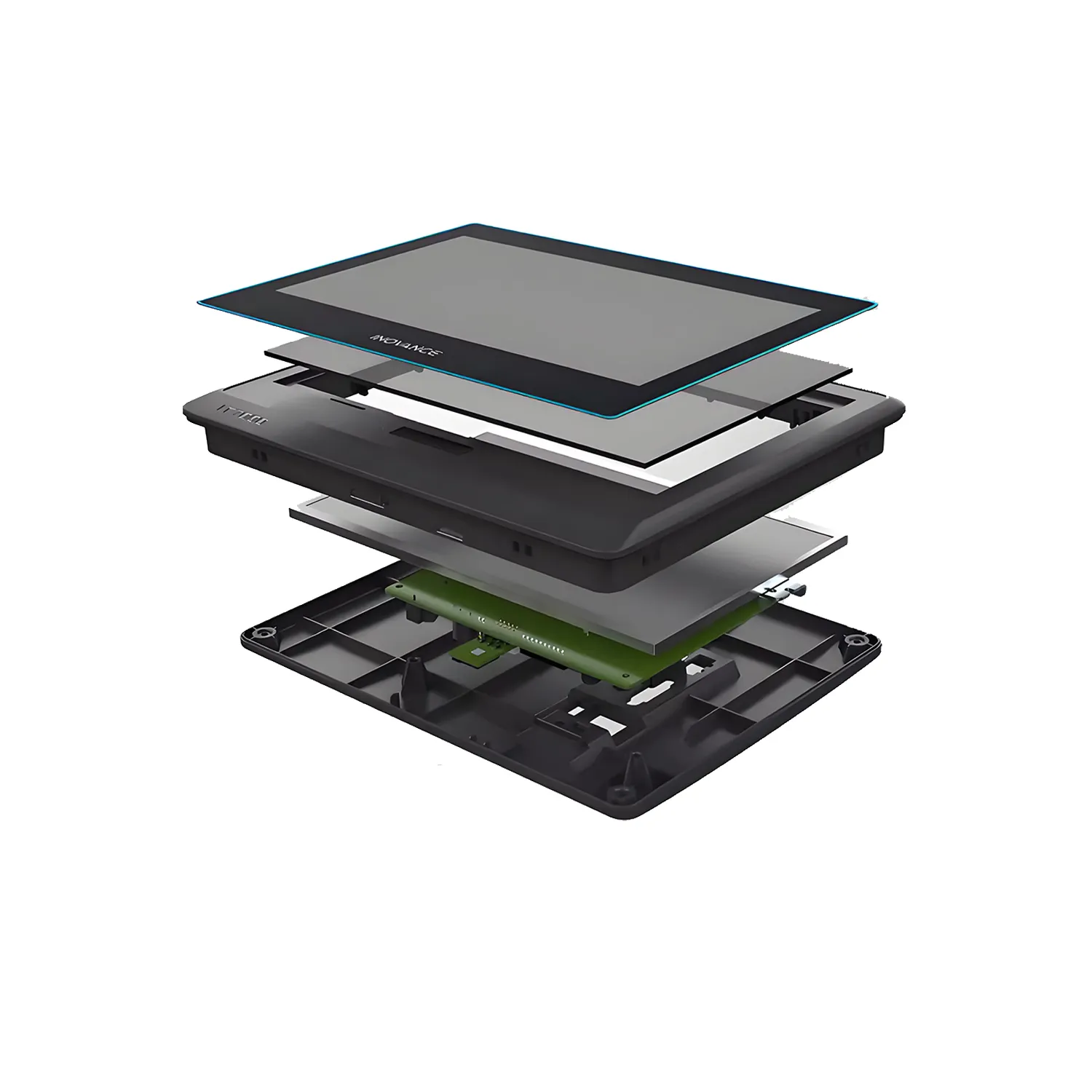

- Type: Hmi Touchscreen Memrbane Layer

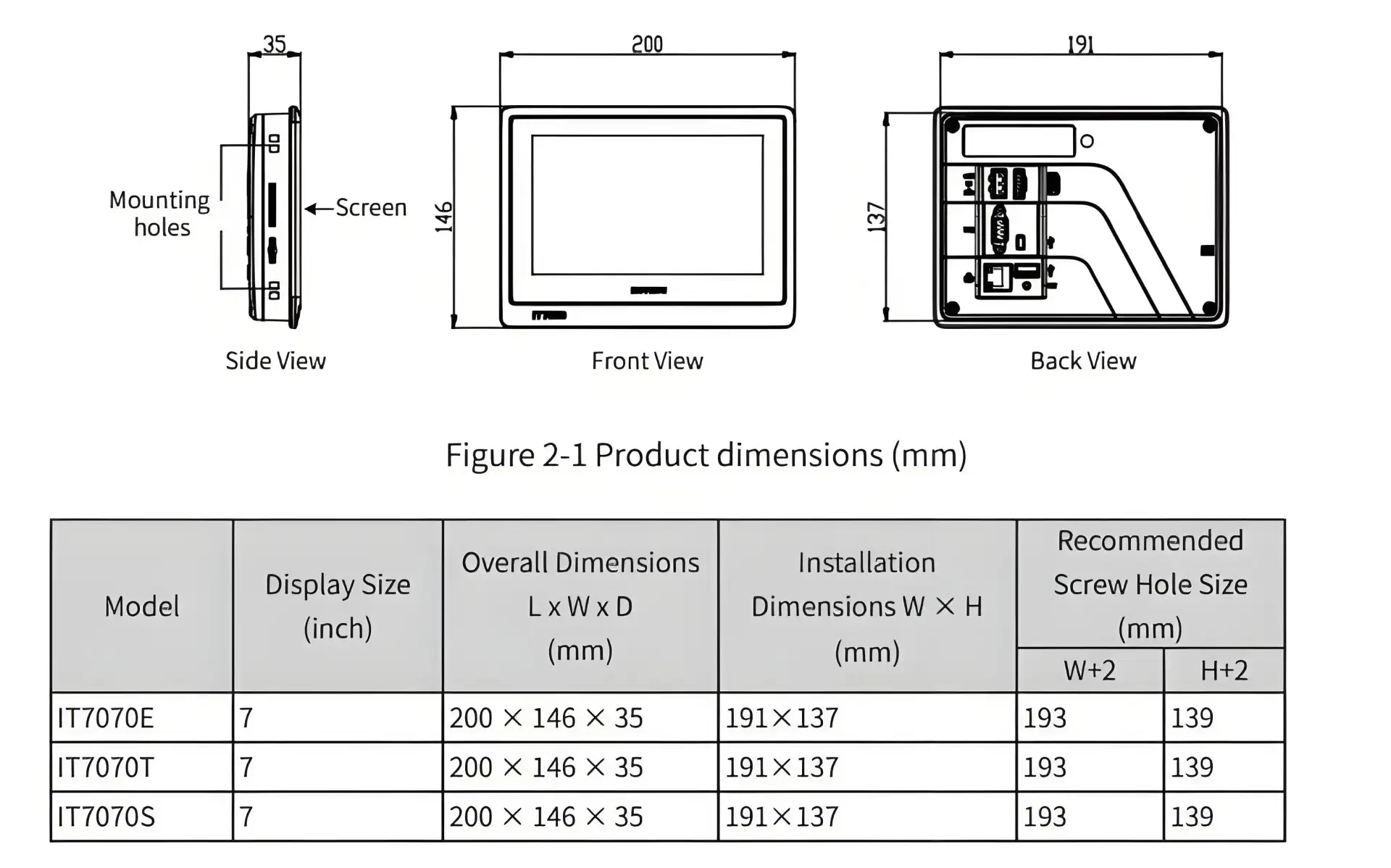

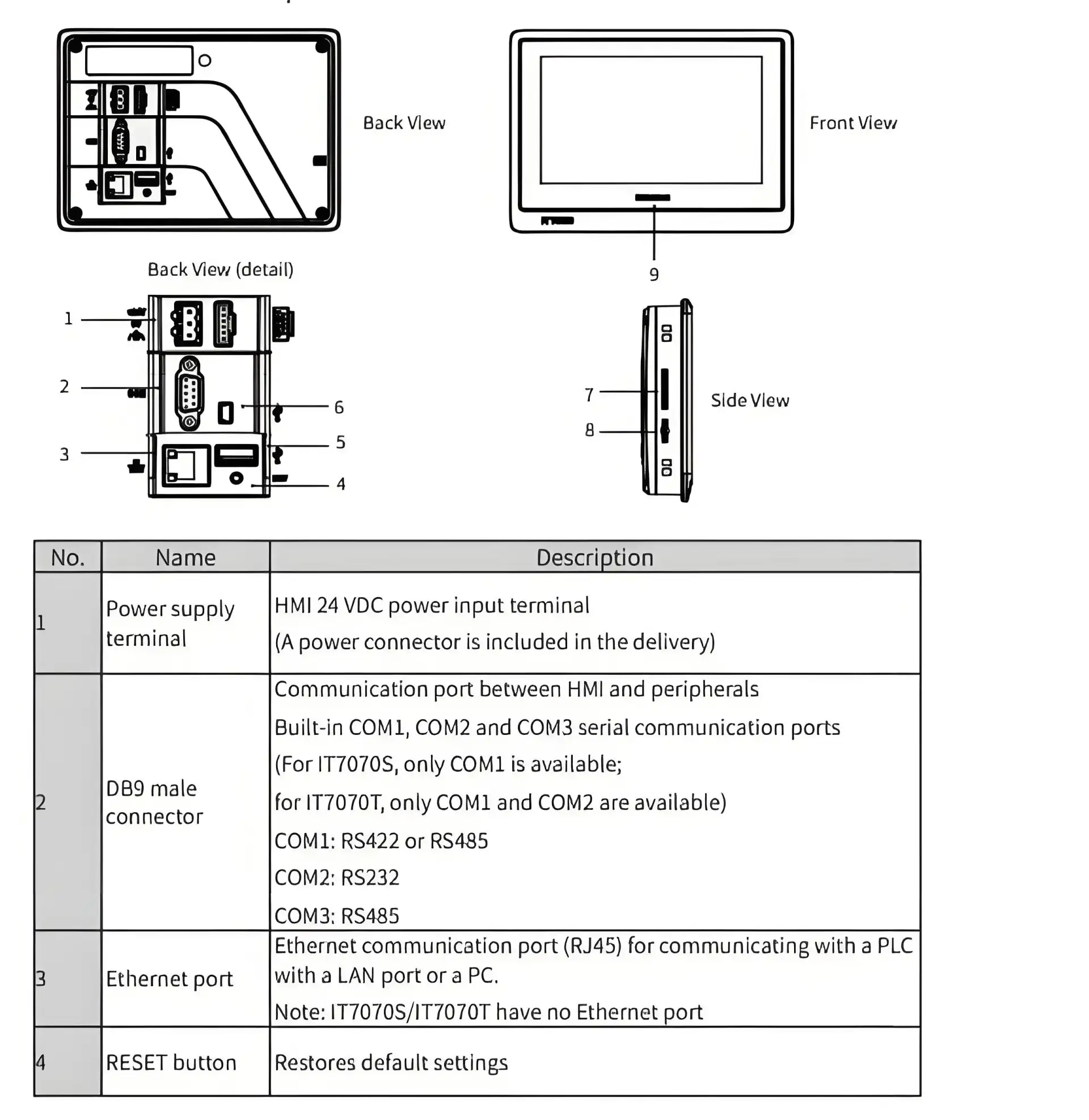

- Part Number: IT6100E IT5100T IT5104E IT7070E/MAM6070 MAM6080 MAM6090

- Size: All size can supply

- Warranty: 1 Year

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now