Filter

Reliable precision filter

Filter

The precision filter of the air compressor is installed in the air compressor system. It is used to further filter out solid particles, oil mist, moisture and other impurities in the compressed air, in order to improve the purity of the compressed air and ensure the normal operation of downstream equipment and product quality.

Filter

- Material: Aluminum alloy/Stainless steel / Plastic

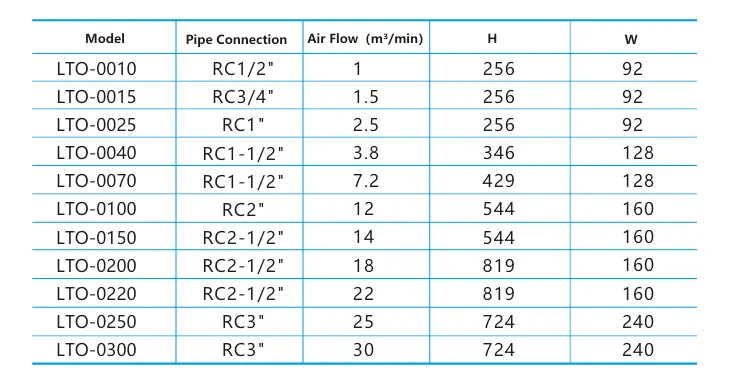

- Pipe Connection : RC1/2"~RC3"

- Air Flow(m³/min): 1~30

- Model: Provide matching solutions based on specific requirements

- Pressure: Match the pressure of the air compressor accordingly

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now