Inverter

We offer frequency converters designed and manufactured specifically for air compressors.

Inverter

The variable frequency converter for air compressors is a special type of variable speed control equipment designed specifically for air compressors. It regulates the rotational speed of the motor to control the exhaust volume of the air compressor, thereby achieving energy savings and stable gas supply.

Inverter

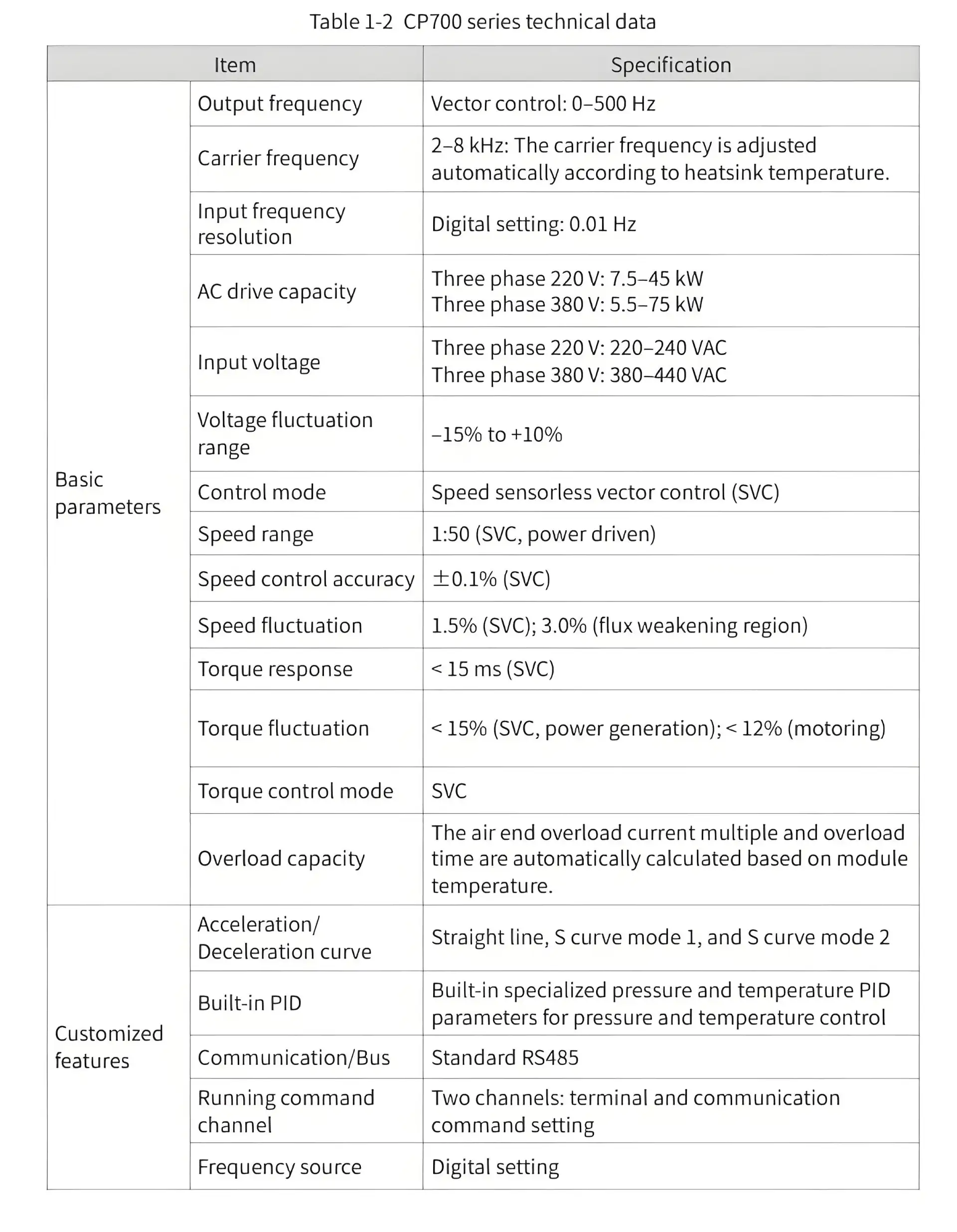

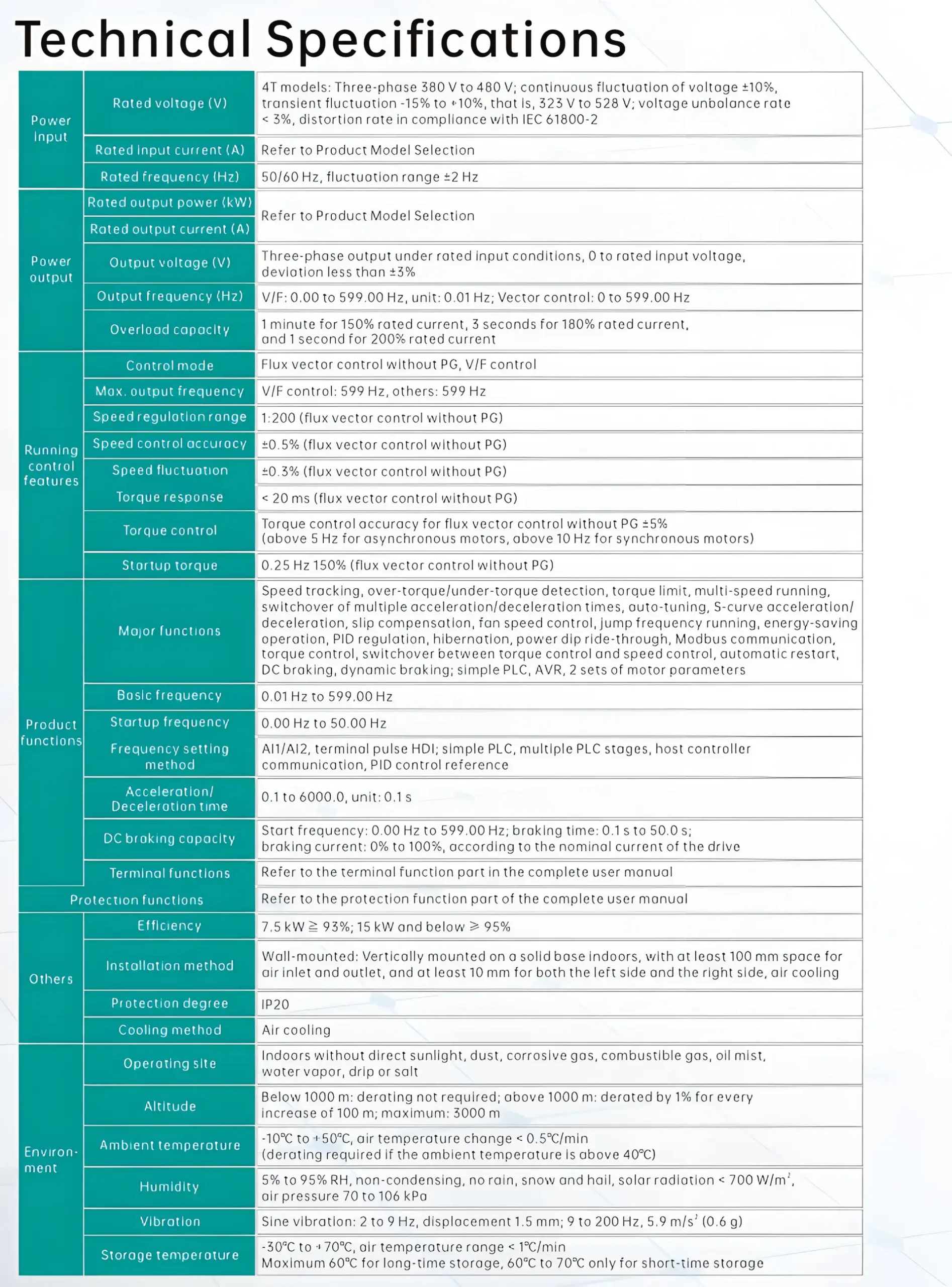

- Output frequency: Vector control: 0 - 500 Hz 2kHz~8kHz

- Carrier frequency: Default carrier frequency: 6K

- Output frequency resolution: Digital setting: 0.01HZ

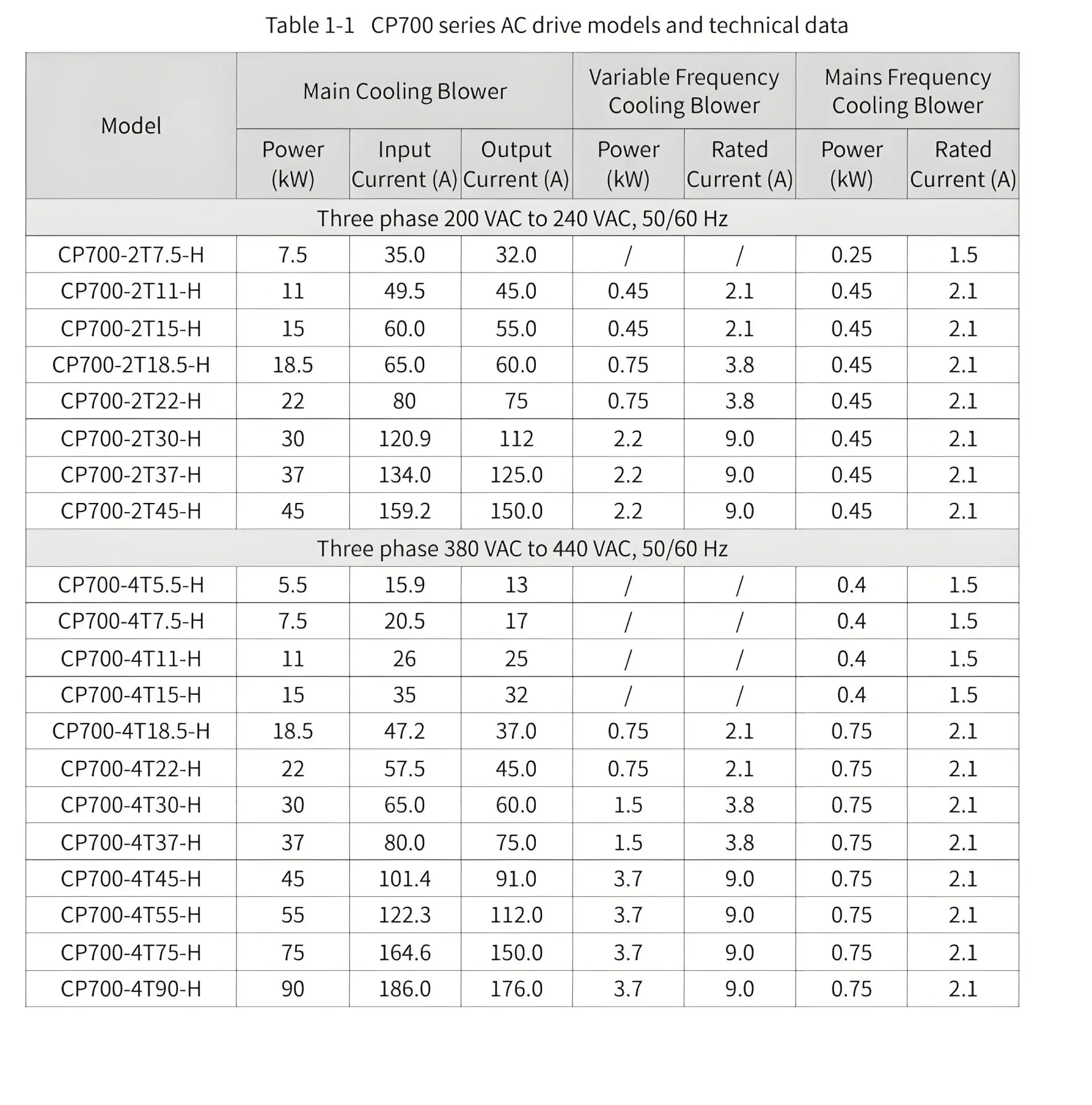

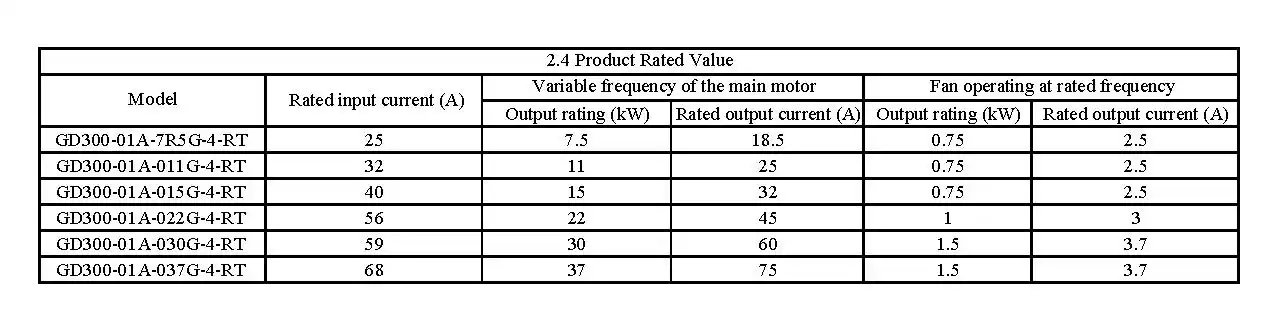

- Inverter capacity Input voltage: 5.5kW~250kW

- Voltage fluctuation range: Three-phase 380VAC ~ 440VAC (-15% ~ +10%): 323V ~ 484V

- Control method: -15% ~ +10%

- Speed regulation range: Speed sensorless vector control, VF control

- Speed control accuracy: 1:50 (SVC electrically driven) ± 0.1% (without sensor vector control)

- Speed fluctuation: 1.5% (without sensor vector control): 3.0% (in weak magnetic zone)

- Torque response: <15ms (without sensor vector control)

- Torque fluctuation: <15% (without sensor vector control, power generation); <12% (electrically driven)

- Torque control mode: Without sensor vector control

- Overload capacit: The overload current multiplier time of the main unit is calculated according to the general fixed overload curve

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now