Membrane separation nitrogen generator

High-efficiency and rapid membrane separation nitrogen generator

Membrane separation nitrogen generator

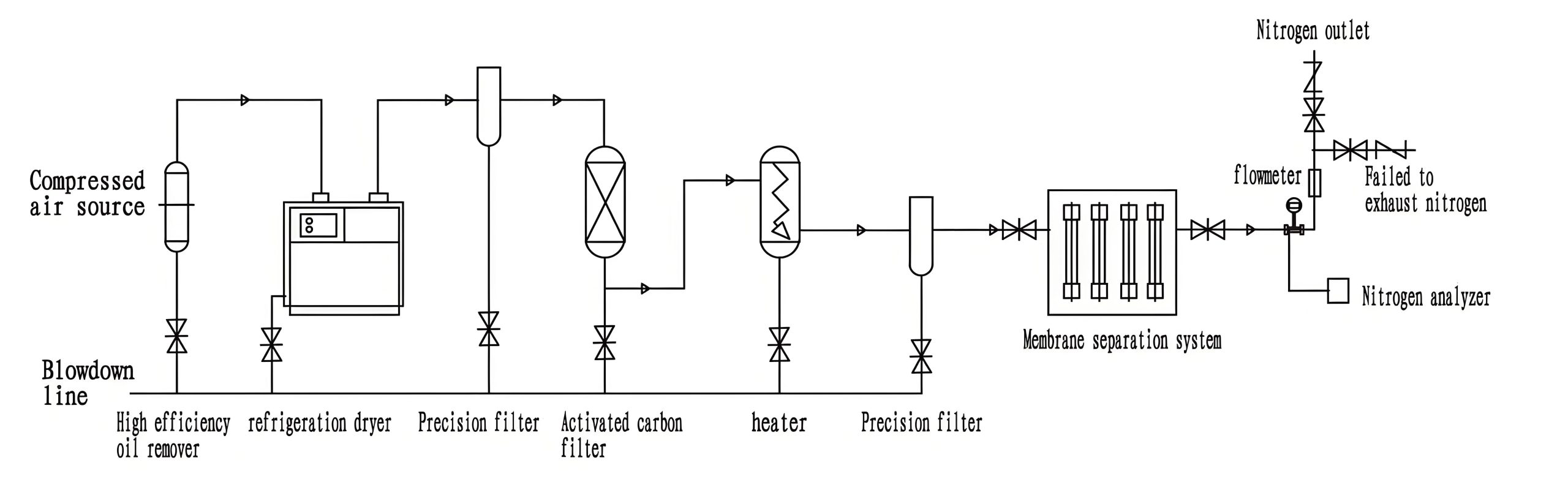

Selective permeation: The core of the membrane separation nitrogen generator is the hollow fiber membrane module. Its working principle is based on the difference in the permeation rates of different gas molecules in the membrane material.

Membrane Separation Nitrogen Generator

- Nitrogen flow rate: 5~30000 Nm3/h

- Nitrogen purity: 95%~99.9999%

- Atmospheric dew point: ≤-45℃

- Nitrogen pressure: 0.05~0.8Mpa

- Dimension(L*W*H): customize

- Voltage: 220V/380V according to your country's voltage

- Weight: According to different plans

- Warranty: 1 Year

- Machinery Test Report: Provided

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now