PSA High Efficiency Nitrogen Generator

High efficiency, energy saving, rapid gas production, compact structure, long service life

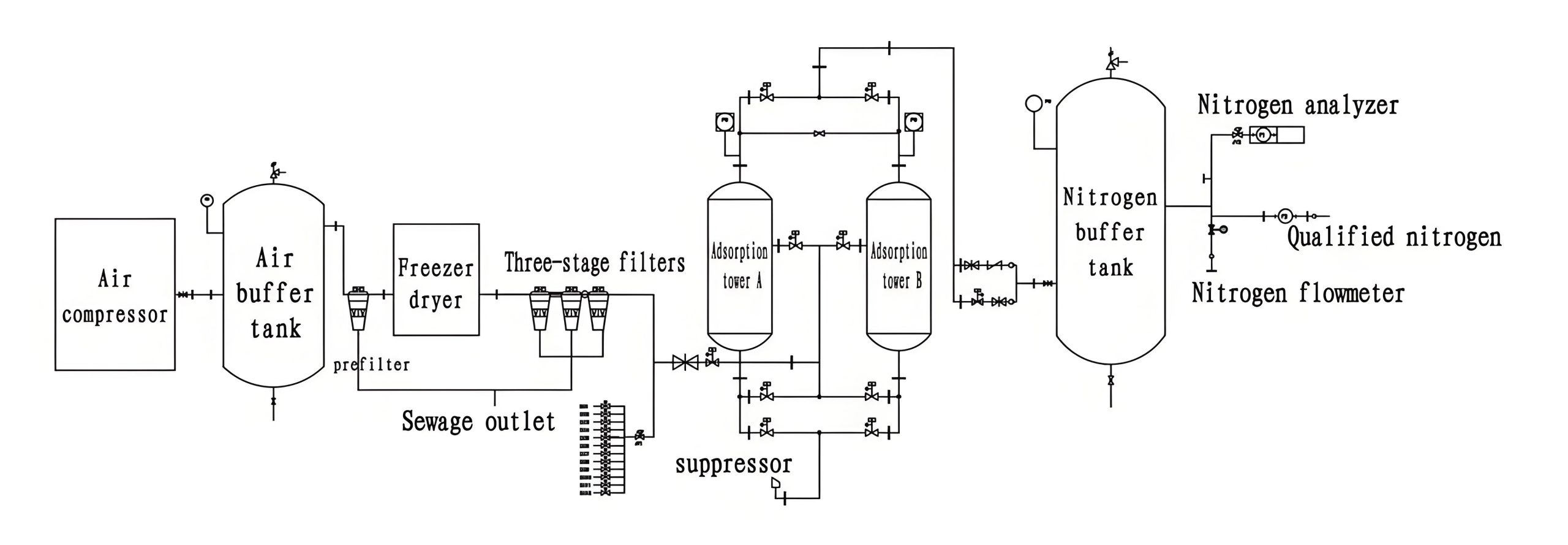

Adsorption-based PSA nitrogen generation device

The PSA nitrogen generation equipment adopts the pressure swing adsorption technology. It uses air as the raw material and utilizes the selective adsorption characteristics of carbon molecular sieves for oxygen and nitrogen to separate nitrogen and oxygen.

The PSA air purification equipment, with its outstanding performance, wide range of applications and convenient operation, has become one of the indispensable important equipment in modern industrial production and scientific research fields, providing users with efficient, stable and reliable nitrogen supply solutions.

PSA Nitrogen Generator

- Nitrogen flow rate: 5~30000 Nm3/h

- Nitrogen purity: 95%~99.9999%

- Atmospheric dew point: ≤-45℃

- Nitrogen pressure: 0.05~0.8Mpa

- Dimension(L*W*H): customize

- Voltage: 220V/380V according to your country's voltage

- Weight: According to different plans

- Warranty: 1 Year

- Machinery Test Report: Provided

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now