Refrigerated Air Dryer

Efficient, fast, energy-saving, high-quality

Refrigerated Air Dryer

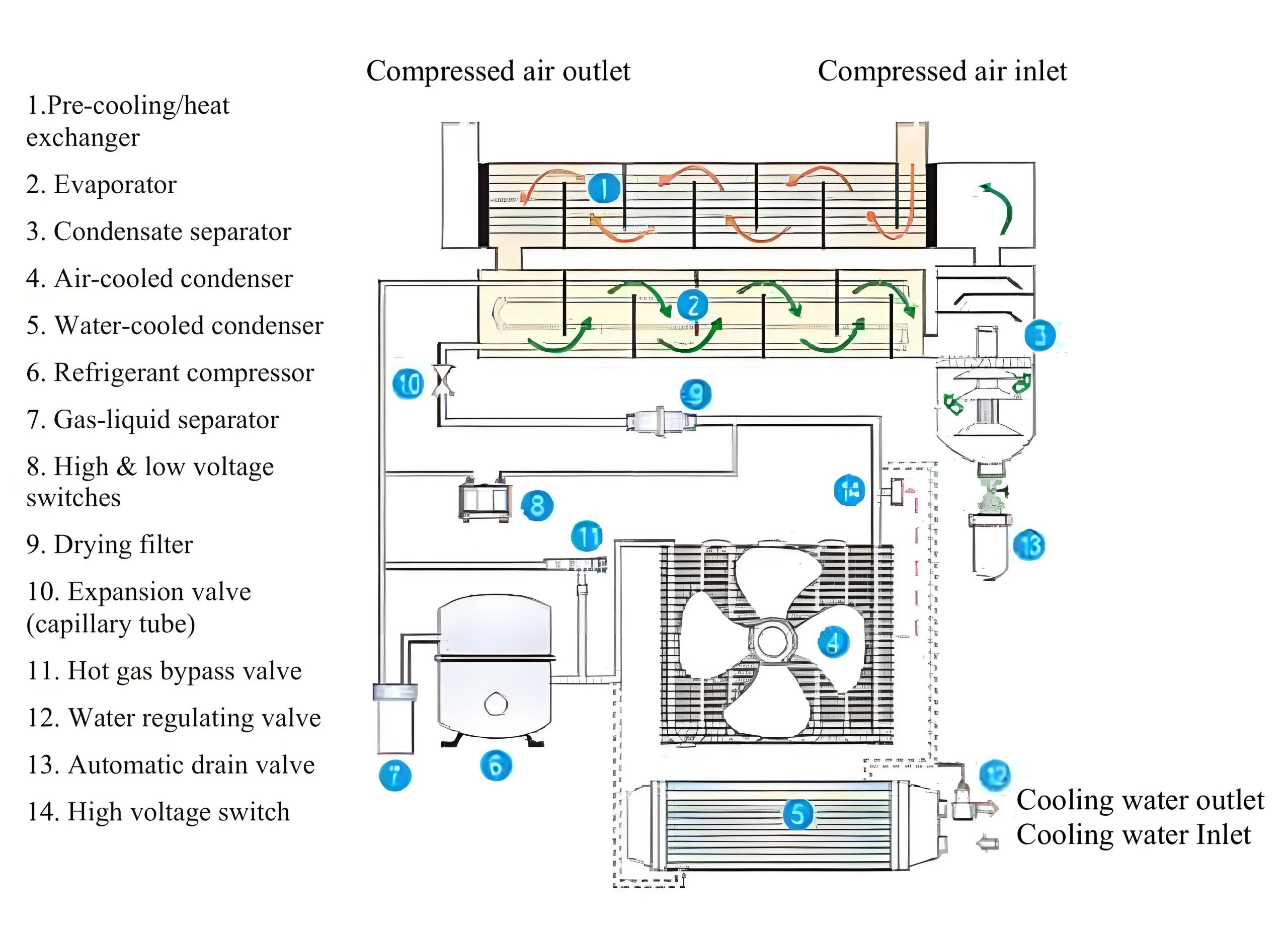

A cold dryer is a device that uses refrigeration technology to dry compressed air. It is widely used in industrial production, food processing, healthcare, environmental protection, energy, transportation, and biopharmaceuticals.

Refrigerated Air Dryer

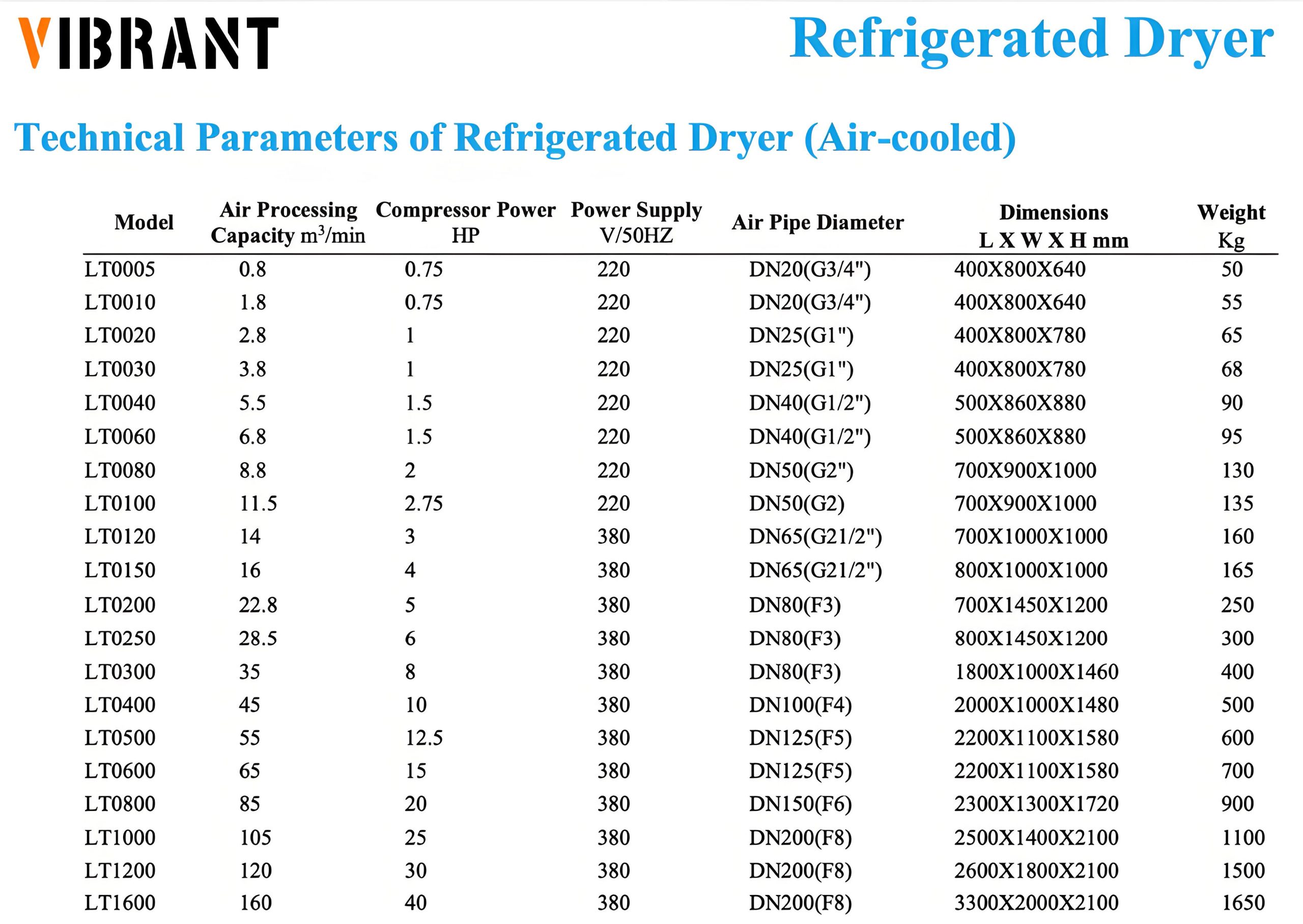

- Air Processing Capacity(m³/min): 0.8~160

- Compressor Power(HP): 0.75~150

- Power Supply: 380V/50Hz,According to customer customization

- Dimensions(mm): 400X800X640~ 5000X2800X3000

- Weight(kg): 50~6000

- Type of cooling: Water-cooled / Air-cooled

-

Energy-efficient

-

Stable operation

-

Low noise

-

Intelligent

Get a quote now