What exactly is a Reliable Fixed Speed Air Compressor?

A Reliable Fixed Speed Air Compressor maintains constant rotational speed, thus providing a steady stream of compressed air. Fixed-speed models operate at a consistent pace, while variable speed compressors adjust their speed according to demand. This construction makes them easy, reliable, and economical for diverse applications across industries and commercial domains. Fixed speed air compressors are best suited for continuous operations where uninterrupted performance is essential. These capture scenarios where a reliable air supply is needed for extended durations, such as manufacturing plants, automotive repair shops, or woodworking facilities.

Turning a Reliable Fixed Speed Air Compressor into a Demanding Applications Powerhouse

The Reliable Fixed Speed Air Compressor is unmatched in performance for the industrial air compressor segment as a Fully Integrated Fixed Speed Air Compressor. This unit delivers air at a constant compressor RPM, achieving a constant air delivery pressure. Air flow is optimized for set speed operation, which works best for applications like manufacturing, carpentry shops, and automotive industries. The basic on-off control makes the unit very simple to use. The features also increase air compressor reliability while reducing operational expenditures over the life cycle of the compressor.

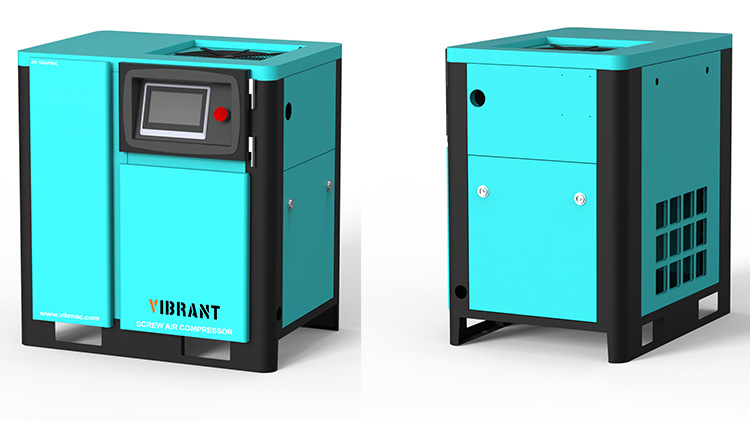

Increased Operating Efficiency while Using VIBRANT Fixed Speed Air Compressor

The intelligent engineering design behind the VIBRANT Fixed Speed Air Compressor ensures these performance targets are met. Claims include achieving maximum output with minimal resource consumption. The third-generation rotor results in enhanced air compression while substantially enhancing the operating efficiency of the compressor system. Oil used for lubrication also serves to cool the unit greatly enhancing operational effectiveness under continuous use.

Maintenance Optimization, Decreased Turnaround Time

Due to its direct-drive structure, the compressor avoids the transmission inefficiencies that occur in belt-drive systems. This enhances operational efficiency and makes maintenance easier. Quick assembly leads to decreased downtime and lower maintenance expenditures, an advantage for situations that cannot sustain production interruptions.

Smart Control System for Optimal Precision

The intelligent controller embedded in the system analyzes field data in real-time, autonomously regulating inlet valve settings to guarantee constant exhaust pressure. This achieves balanced performance in all ranges of operation and true commercial-grade robustness.

Why Select a Dependable Fixed-Speed Air Compressor?

Long-Term Effectiveness

A dependable fixed speed air compressor is built to serve for years with only minimal servicing. Due to the simplicity of the system, there are fewer moving parts, which directly correlates to less wear and tear. With a heavy-duty fixed speed air compressor, you get an industrial-grade solution that works without fail for prolonged periods.

Minimal Servicing Required

Fixed speed air compressors stand out due to their servicing requirements being low. As they operate at a constant rate of rotation, their lack of electronics and mechanical parts ensures that there are no failures, which are common in variable speed compressors. This is important for many firms that aim to cut down their operational downtime.

Eco Friendly

The initial pricing of fixed-speed compressors is also far lower than variable speed compressors, making it a more accessible option. These compressors should be the model of choice for low-demand periods despite their short-term energy consumption. The on-off switching method, however, guarantees that energy consumption is optimized during periods of increased demand.

Best Suited for Continuous Operation

For tasks requiring continuous air pressure to be supplied, fixed-speed air compressors are best suited. They can be used to power pneumatic tools in a workshop or used for spray painting in an industrial setup. A constant speed air compressor will always be there to deliver steady, uninterrupted service.

Uses of Fixed Speed Air Compressors

With their range of benefits, fixed-speed air compressors can be used in different fields and sectors. Here are some of the most common ones:

Industrial Application:

Reliability in the industrial field is a must. An industrial fixed-speed air compressor takes care of the large-scale operations, such as manufacturing in a processing plant or running an assembly line, without disrupting the flow of work. These systems are designed to work for long hours under high demands.

Commercial Application:

A commercial fixed-speed air compressor is ideal to support air requirements in businesses such as car-repairing shops, woodworking shops, and construction sites. For commercial maintenance and repair businesses, oil-lubricated fixed-speed air compressors offer a consistent and reliable air supply. Their needs for repairs and upkeep are low, increased efficiency leading to less frequent maintenance.

Tools for Automobiles and Pneumatics:

In the automotive industry, pneumatic tools commonly use fixed speed compressors. For tasks such as paint jobs, tire servicing, and brake work, a dependable fixed-speed air compressor is an absolute must. The provided performance from fixed speed air compressors for vehicles is constant, and pressure is consistent, which improves work and productivity.

Benefits of Reliability in Fixed Speed Air Compressors

Improved Productivity

Fewer breakdowns result in increased productivity, and reliability provides just this. Along with a business’s operational efficiency, productivity will also increase with the use of a fixed-speed air compressor. With fewer downtimes, the workforce can concentrate on more income-generating activities.

Overall Reduced Cost of Ownership

Purchasing a fixed-speed air compressor is an excellent investment because it significantly lowers business expenses. The anticipated lower maintenance costs, extended lifespan, and reduced energy will all welcome businesses to optimize other sectors for profit.

Controlled Air Quality

The reliable fixed speed air compressor in use is likely to have sophisticated filters that guarantee that its output air is of high grade. This is crucial to some fields like electronics because they need clean and dry air in the case of very delicate jobs.

Selecting the Best Reliable Fixed-Speed Air Compressor

When it comes to buying the best reliable fixed speed air compressor, take into account the following aspects:

• Your Application Outlook: What is the requirement of the air demand? What is the amount of air needed? Make sure the compressor will be appropriate for all your applications.

• Tools Used: Do you operate with high-pressure demanding tools or low-pressure tools? Is low pressure sufficient? If the demand is high pressure, consider using a two-stage fixed-speed air compressor.

• Efficiency of Power: Generally, fixed-speed compressors are less energy efficient than variable-speed models, but make sure to check for energy-saving features like thermal shutdown or overload protection.

• Dimensional Relations: Verify that the size of the business is well-matched to the size of the compressor. Small businesses will need compact fixed-speed air compressors, while industrial operations require larger systems.

Conclusion

Taking up a fixed-speed air compressor will offer your business's performance a consistent and long-lasting boost. Whether you require a rugged fixed-speed air compressor for industrial use or low-maintenance options for small workshops, these machines are designed to cater to your specifications. Pay attention to durability, efficiency, and reliability to ensure optimum value for your investment. For high performance and reliability, machined air compressors and industrial-grade air compressors, visit VIBRANT, where several more options await.