What Is a Screw Air Compressor?

A screw air compressor is a specific kind of rotary compressor that employs two helical rotors (screws) for air compression. Considered a positive displacement type, this compressor has the advantage of providing a constant flow of compressed air, making it the go-to choice for industrial applications because of its longevity, low noise, and ability to run continuously.

How Does A Screw Compressor Work?

Within the housing of the compressor, there are two rotors, a so-called male and female rotor, that rotate in reverse directions to each other. Air is sucked into a compression chamber and is bound in the lobe space. As the rotors turn, the volume between them expands, lowering the pressure of the gas. This gas is then propelled through some form of an air treatment system, normally consisting of an air dryer and air filter, before being routed to the tools or machine.

Why VIBRANT Screw Air Compressor Is the Top-Rated Industrial Choice?

VIBRANT screw air compressor is the unrivaled leaders in vertical markets for high-performance air compression. Our compressors are unmatched with unparalleled energy efficiency, durability, and cutting-edge technology and are built to sustain continuous-duty operation in manufacturing, automotive, construction, and more.

Two-Stage Screw Air Compressor: Maximum Power, Minimum Energy

VIBRANT has an entire series based around a two-stage screw air compressor. This particular model is aimed at businesses that need high levels of air pressure while maintaining low energy expenditure. The compression cycles are done in two steps: “First Stage: Ambient Air Intake and Compression,” where air is drawn in and is then compressed, and the Second Stage includes passing cooled air through a subsequent compressor stage for higher pressure.

This two-screw, two-stage compression system delivers a whopping 15% additional energy saving when pitted against the two-stage compressors. Furthermore, the addition of inter-stage cooling to maintain stable temperature aids in making this system ideal for high-demand and high-temperature environments.

Smart, Stable, and Silent Operation

Quiet Performance

VIBRANT compressors greatly enhance the noise pollution levels of the workplace, particularly for indoor environments, alleviating most unwanted noise with low vibration twin screw technology.

PM Motor Technology

The PM motor installed in the VIBRANT units is capable of providing stable power output with a low chance of failure, therefore increasing uptime and reducing maintenance needs.

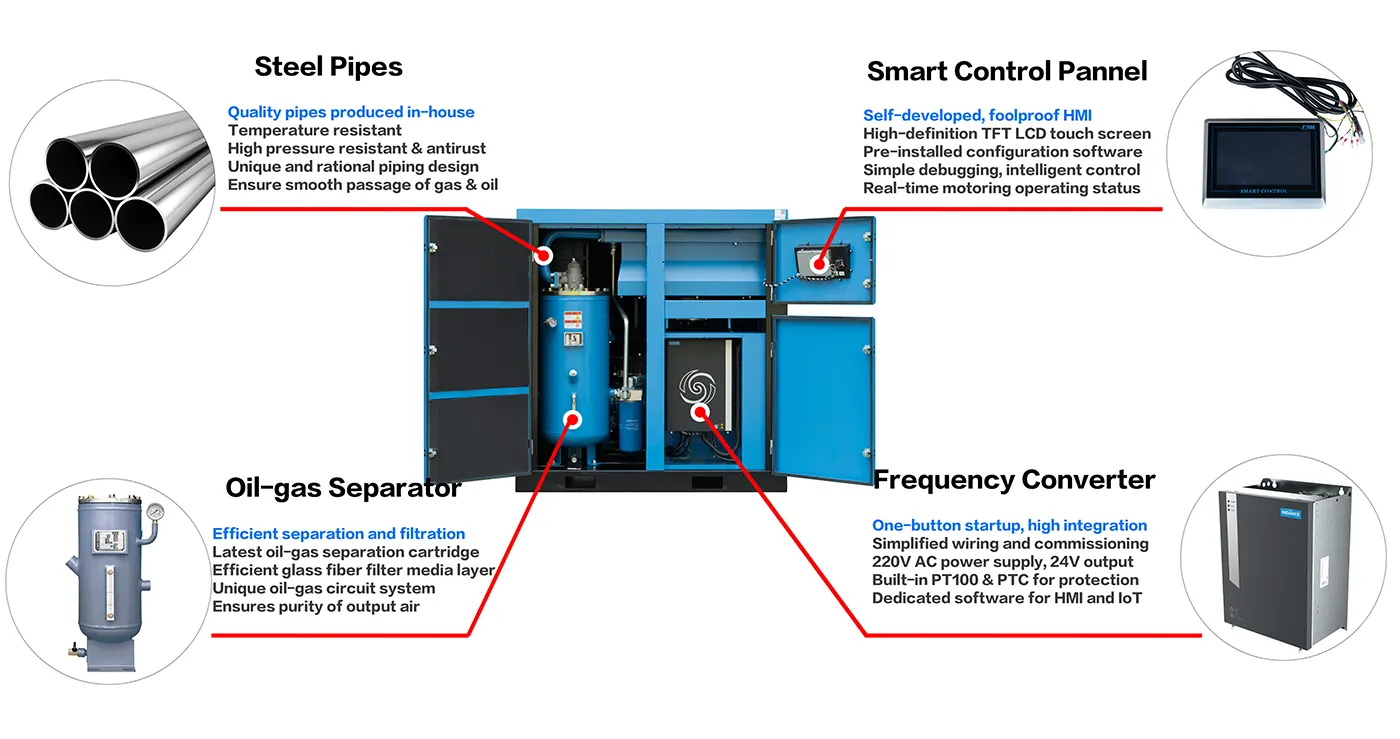

Intelligent Control System

Every unit has a control panel with high intelligence that works with several frequency inverters. The entire system is capable of controlling the following parameters:

1.Air Output

2.Exhaust Pressure

3.Operating Temperature

This enables accurate performance control to maximize efficiency regarding energy expenditure and supply air to meet demand, particularly suited for VSD applications.

Custom Control and Modern Features of screw air compressor

At VIBRANT, technological advancement commences from the grassroots. The company makes it a point to design and manufacture control panels and raw inverters to serve different industrial applications. These proprietary controls are intended for simple plug-and-play use, whether for stationary air compressors in a factory or for powering pneumatic tools on the field.

Are you on the lookout for an all-in-one screw air compressor with an integrated air dryer? Check out our VIBRANT compact units designed for both performance and space efficiency.

For Use with High-Temperature and High-Pressure Applications

VIBRANT high-pressure screw compressor system includes:

- Rare metal for rotors due to its resistance to wear

• Temperature resistant components

• Dual stage compression for safe, efficient performer.

All of these additions give you unparalleled safety and durability, even in the most industrial environments.

Energy Efficient, Eco-Friendly-Tech

Modern day businesses look to go eco-friendly. VIBRANT’s variable speed screw air compressors seek to provide green energy solutions that ensure global environmental measures are met alongside cutting down electricity costs. The system adapts to real-time output requirements, which makes sure no energy is wasted.

Why Choose VIBRANT?

Should you require a reliable air compressor, operates quietly and works in an energy-efficient manner, VIBRANT will be your best choice. Their two stage screw air compressors include:

- May save energy usage by 15%

- Lowers maintenance as well as quiet function

- Major intelligence systems with calibrated control

- Capsules are designed for 24-hour, 7-day-a-week industrial work usage.

VIBRANT provides unique satisfaction and trust for people even running these in construction sites, pharmaceutical plants, or automotive workshops.

Uses Indoors and Outdoors of compressor

Automotive

There is everywhere is compressed air from the assembly line to the paint booth. It is important to have a noiseless screw air compressor to keep everything consistent and efficient.

Construction:

Pneumatic equipment such as nail guns and jackhammers are operated using portable screw air compressors.

Pharmaceuticals:

In this economic world, oil-free compressors are a necessity.

Key Features and Benefits

Energy-Efficient Compressed Air Technology

Utilize power through VSD screw compressors. It’s both eco-friendly and budget-friendly, as it reduces carbon emissions and electricity bills.

Quiet Industrial Operation

Less noise creates an Improvement in working conditions. Especially indoors.

Reliable Continuous-Duty Performance

Run your compressor non-stop at 24/7 without overheating or wear and tear. Made for non-stop power.

Low Maintenance

These have fewer moving parts than piston compressors, resulting in minimal breakdowns.

High Air Flow and Consistency

Consistently deliver air pressure to demanding equipment.

Compact and Sleek Design

Saves valuable floor space—especially in urban plants or containerized solutions.

Selecting The Best Screw Compressor

Below are some guidelines to note:

Air Demand

Establish your CFM requirements. Do not oversize – it accounts for energy loss.

Duty Cycle

Is the usage continuous or intermittent? Long runs is what screw compressors prefer.

Environment

Are you in a cleanroom? If yes, go oil-free. If looking for outdoors, go portable.

Energy Efficiency

When demand is variable, select a unit with adjustable speed. That pays you very quickly.

Maintenance & Support

Confirm the availability of spare parts as well as ease of servicing.

Vibrant has your back with full air compressor maintenance and parts support.

Why Vibrant is the industry leader in screw compressors?

Vibrant is committed to manufacturing tailored full industrial grade screw air compressors. Our models are:

•Energy Star rated

•Compact and quiet

•Built for continous duty

•Available in oil-injected and oil-free variants

•Professional service and support offered

Whether you need a stationary screw air compressor with dryer and make for rugged use, or portable unit, Vibrant has units geared for your purpose.

Conclusion

A screw air compressor is more than equipment- it is a core driver of productivity, reliability, and sustaining costs. As technology evolves and industries become more powerful, the demand for compressed air systems that are ultra quiet and require minimal supervision has reached new heights. Pick the right model. Maintain it well, and it will serve you for years to come. Looking to step up your air compressor game? Check out our new models.