Screw compressor for a factory in Mexico is no longer considered just equipment; but as a significant element of this equipment, it can guarantee the continuous output, the optimum energy consumption, and the long-term stability. Mexican manufacturing plants, which range from vehicle makers to food processing plants, rely on state-of-the-art infrastructures powered by compressed air in the country.

The Reasons to Go with a Screw Compressor in Your Mexico Factory

Factories in Mexico are increasingly becoming fans of screw compressors because of their dependability and energy-saving capabilities. Contrary to the system based on the pistons, a screw compressor in the factory in Mexico provides compressed air without an air pulse, which is why it is optimal to consider such a compressor when it comes to industrial processes conducted in the factory that require a constant stream of air. These compressors are designed on rotary screw technology that enables them to perform smoothly, quietly, and efficiently. Longer duty cycles, fewer wear and tear, and little repair duty are the advantages enjoyed by factories. It means reduced idle time and increased output level in the production lines.

This is why a screw compressor is a good buy:

•Better energy efficiency, which reduces the power bills.

•Low noise, better working in conditions.

•Constant air flow, suitable for delicate equipment.

•Generic Stress and Endurance.

•Easy maintenance minimizes the cost over the long run.

Regardless of whether you are building your plant in Monterrey, Guadalajara, or Mexico City, the right screw compressor will increase its efficiency and contribute to sustainable production.

The Best Screw Compressor to use in a Factory in Mexico - PM VSD Screw Air Compressor

When you need to find a Screw Compressor for Factory in Mexico to apply in a factory, you should consider using the PM VSD Screw Air Compressor because it is highly efficient and smart equipment. This air compressor has the most advanced permanent magnet motors and variable speed drive (VSD) technologies, which make it the most energy-saving, accurate, and durable air compressor that will suit heavy industrial applications in Mexico.

High Efficiency

The permanent magnet synchronous motor fitted in PM VSD compressors helps to obtain 3-5 percent above the efficiency produced by standard motors. Its distinction from others is that such high efficiency does not change over its range of speeds, and hence, one can save energy consistently at lower load requirements. This is a competitive advantage experienced by the factories in Mexico that are keen on sustainability and minimal costs of operations.

Fast Maintenance

Easy and faster maintenance is among the fundamental advantages of the PM VSD Screw Air Compressor. There are fewer consumable parts, and the simple design allows replacements to be easily effected by technicians, cutting down the loss of time to a minimum. It is therefore very applicable in industries where its uptime is very important, like studying the automotive, medical, and textile industries in Mexico.

High Safety Regulation

The system is made to be very safe. High-technology PTC temperature sensors are utilized, which are supervised through an intelligent controller. In case of abnormal temperatures, protection mechanisms are automatically activated so that the system prevents the motor burnout and equipment failure. This safety feature helps in keeping the whole production line stable and going during the challenging requirements.

Portable, Low Noise, and Dependable Operation

The compressor is made of high-strength materials, ensuring stable performance with low vibration and noise that lowers wear and enhances working conditions. This qualifies it very well for indoor factories or areas that have to operate with minimal noise, like precision assembly lines in Mexico.

Industry Applications

The PM VSD Screw Air Compressor is common in the automotive industry, medical industry, and textile industry across Mexico. It provides a clean, efficient supply of compressed air to the business, which will enable the business to have sound compliance with the environmental standards, and also raise productivity.

Technical Advantages of the Rotary Screw Compressors

Rotary screw air compressor is an innovative powerhouse. These are some of its best characteristics:

1. VSD or Variable Speed Drive

Variable speed control on the motor based on air requirement, which saves up to 35 percent of energy.

2. Dual-Rotor System

Allows steady and constant air flow to reduce wear and tear.

3. Oil-Injected Models

Increase the life cycle and improve lubrication.

4. Smart Control Systems

More up-to-date units have programmable logic controllers (PLCs) to ensure control.

Mexican factory Custom Air Compressor Solutions

Each factory is in need of its own requirements. Here at VIBMAC, our expertise lies in custom air compressor services for the Mexican industries. We do the analysis involving factors such as:

•Demand for air flow (CFM)

•Pressure needs (PSI)

•Business hours

•Limitation of space

•Considerations of the cost of the budget and energy

Our expert recommendations are presented, whether you require a heavy-duty screw compressor to operate 24/7 or a small one that will fit into your small places.

Procuring/Purchasing Tips: Mexico Sources of obtaining Screw compressors

Interested in purchasing a screw compressor for your factory in Mexico? The following are the important considerations:

Tips to Get the Best Uptime Maintenance

It is important to maintain all the proper maintenance to minimize any downtime and costly repairs. These are important suggestions:

Preventive maintenance should be done every 500-1000 hours

•Inspect the level of oil and change filters regularly

•Check hoses and belts to see if they are worn out

•Observe the level of temperature and pressure

Outsource your maintenance so that you can achieve consistency as local authorities do.

Why VIBMAC is Your Reliable Supplier?

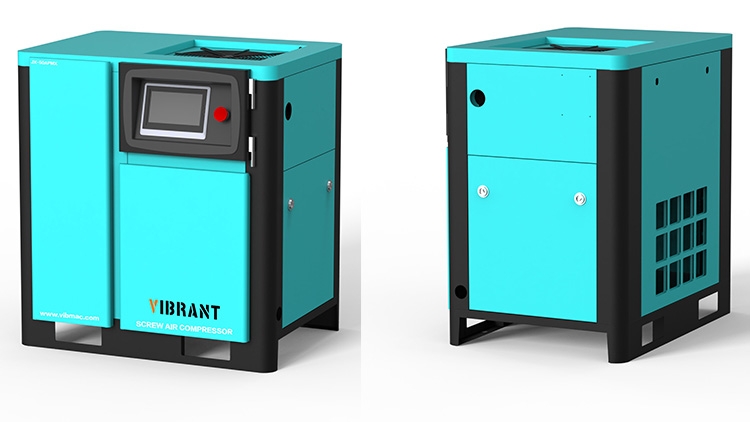

In case of choosing a screw compressor for a factory in Mexico, reliability, efficiency, and serviceability are essential. We offer the 3 at VIBMAC. Having nearly a decade of experience in the market and industry of air compressors, our enterprise has excelled in supplying efficient compressed air technology based on the needs of the Mexican manufacturing industry, whether it involves car manufacturing, textiles, or electronics industries.

VIBMAC is different; we are committed to energy-saving technology and factory-grade reliability. Our PM VSD screw compressors are system-built in such a way that they respond to sudden changes in load, both in terms of air pressure as well as downtimes. We offer:

- Intelligent control systems of a variety of screw air compressors.

- On-ground local support in Mexico, to have fast service and maintenance.

- Eco-friendly models are made with low-emission and low-noise construction.

VIBMAC also develops fundamental technologies constantly, but maintains the traditional quality standards of our machines. Our compressors are of the latest standards in terms of efficiency, durability, and environmental conservation.

Conclusion

As far as the factory compressed air systems are concerned, issues of reliability, efficiency, and local support are not negotiable. Invest in a solution that could meet the industrial demands of a Screw Compressor for Factory in Mexico chose a VIBRANT compressor. The PM VSD model can offer high performance to the businesses in Mexico that are in seek of a reliable yet energy-efficient and low-maintenance screw compressor. It does not matter where your factory is: Monterrey, Guadalajara, or Mexico City, this compressor has been engineered to support your industrial air demands with innovation and reliability.