In the world of air conditioning, refrigeration, and industrial air systems, scroll compressors and rotary compressors are two of the most widely used positive displacement compressor types. While both serve the purpose of compressing air or refrigerant, they differ significantly in internal design, energy efficiency, noise levels, and ideal use cases. This guide breaks down the key differences between scroll and rotary compressors, helping you choose the best option for your specific application.

1. Basic Design and How They Work

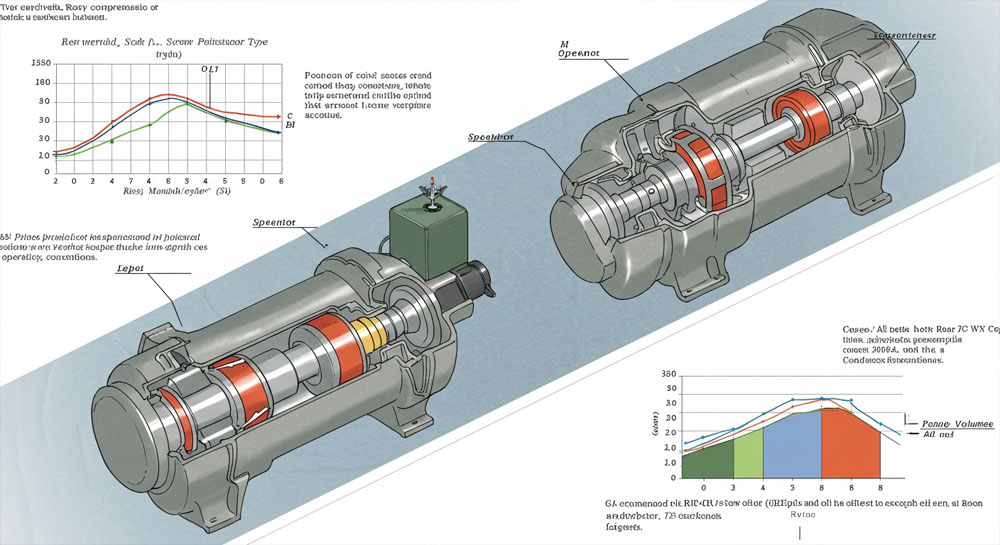

Scroll compressors use two spiral-shaped scrolls — one stationary and one orbiting — to compress air or refrigerant. As the orbiting scroll moves, it traps and compresses gas in gradually tightening pockets. This design leads to smooth, continuous compression with minimal moving parts.

In contrast, rotary compressors cover several types, including rotary vane, rolling piston, and screw compressors. Most notably, rotary screw compressors use twin helical rotors to compress gas efficiently and continuously. The compressed gas exits in a steady flow, making these ideal for industrial use.

2. Efficiency and Energy Performance

- Scroll compressors are known for their high volumetric efficiency, especially in partial load or variable-speed conditions. Their design eliminates valves and minimizes internal leakage, which enhances energy savings and reduces power consumption.

- Rotary screw compressors, while often used in high-capacity, continuous-duty environments, are also very efficient. Their uninterrupted compression cycle makes them well-suited for factories and processing facilities that require constant airflow.

In general, scroll compressors excel in small to medium loads, while screw compressors dominate in high-demand industrial systems.

3. Noise and Vibration

- Scroll compressors operate with significantly less noise and vibration compared to rotary types. Their smooth compression cycle, lack of reciprocating parts, and fewer components contribute to a quieter experience, ideal for hospitals, offices, and residential HVAC systems.

- Rotary compressors, especially screw types, can be noisier due to gear engagement and rotor interaction. Although modern designs have improved noise isolation, they are still louder than scroll types and usually require soundproof enclosures in sensitive environments.

4. Maintenance and Reliability

- Scroll compressors have fewer moving parts and no complex valves, making them generally more reliable and easier to maintain. Their sealed and compact design results in fewer breakdowns, though their performance is sensitive to precision manufacturing and high-pressure operating conditions.

- Rotary compressors involve more components and may require more frequent maintenance, especially in dirty or high-duty environments. However, rotary screw compressors are built for durability and long runtimes under tough conditions, often outlasting scroll compressors in heavy-duty applications.

5. Size and Installation Requirements

- Scroll compressors are compact, lightweight, and space-efficient. Because of their minimal vibration, they don’t require large anti-vibration mounts and can be installed in tighter spaces, including rooftops, closets, or compact mechanical rooms.

- Rotary compressors, especially screw types, are larger and heavier. While they can be scaled up to hundreds of horsepower for industrial use, they require more installation planning, such as proper foundation, ventilation, and sometimes even dedicated compressor rooms.

6. Ideal Use Cases

| Compressor Type | Ideal Applications |

|---|---|

| Scroll Compressor | Residential HVAC, light commercial air conditioning, medical buildings, office units |

| Rotary Compressor (Screw) | Industrial manufacturing, PET bottle blowing, packaging plants, high-volume airflow systems |

Scroll compressors dominate residential and small commercial air conditioning due to their quiet operation and efficiency. Rotary screw compressors, on the other hand, are the go-to choice in demanding industrial settings where continuous airflow and rugged durability are needed.

7. Cost and Value Considerations

- Scroll compressors may have slightly higher upfront costs per unit of capacity compared to small rotary compressors, but they compensate with lower energy bills, minimal maintenance, and greater efficiency under variable load conditions.

- Rotary compressors, particularly screw types, require a larger investment but deliver value in long-term operational stability and energy savings for high-duty use. They are ideal when reliability and output capacity outweigh initial purchase costs.

8. Selection Tips and Decision Criteria

Before choosing between a scroll or rotary compressor, consider these five key factors:

- Airflow Demand: Determine your maximum and average flow requirements.

- Duty Cycle: Are you running the compressor continuously or intermittently?

- Noise Sensitivity: Scroll compressors are ideal for low-noise environments.

- Maintenance Preferences: If you want a lower-maintenance option, scroll compressors may be better.

- Budget & ROI: Balance your initial budget with long-term operating and maintenance costs.

9. Example Scenarios

- A commercial office HVAC system would benefit most from a scroll compressor due to its quiet, efficient, and compact performance.

- A factory operating an automated production line with high air demand should opt for a rotary screw compressor to ensure uninterrupted air supply and long-term durability.

10. Final Summary: Which Should You Choose?

| Feature | Scroll Compressor | Rotary Screw Compressor |

|---|---|---|

| Noise Level | Very low | Moderate to high |

| Maintenance | Low maintenance, few moving parts | Requires regular servicing |

| Efficiency | High at variable/partial loads | Excellent at full/continuous loads |

| Initial Cost | Moderate | High (but scalable for large systems) |

| Use Case | HVAC, quiet spaces, intermittent use | Industrial, 24/7 operations, heavy usage |

Bottom Line:

- Choose scroll compressors for quieter, energy-efficient, compact setups in residential or light commercial settings.

- Choose rotary screw compressors when you need robust, continuous performance in industrial or high-demand applications.

Still not sure which compressor is best for your system? Reach out to our technical team at https://www.vibmac.com/ for a customized consultation based on your needs.