Backbone of Industrial Power

A three-phase motor is an alternating-current machine designed to run on a three-phase power supply, which in turn creates a rotating magnetic field (RMF) within its stationary stator. That moving field pulls on the rotor, changing electrical power into useful mechanical work. Engineers rely on these motors for everything from factory conveyor belts to high-capacity irrigation pumps.

Because they draw power evenly across all three phases, such motors waste less energy, cost less to operate, and can bear heavier loads than their single-phase cousins. As a result, they have become the default choice for almost any large-scale industrial setting.

How a Three-Phase Motor Works

At its core, a three-phase motor operates on a straightforward yet clever idea: electromagnetic induction.

1. Stator: The fixed outer shell, wrapped in coil windings linked to the three-phase supply.

2. Rotor: The inner rotating part, usually fashioned as a rugged squirrel-cage or a wound assembly.

3. When electricity enters, the stator coils create a revolving magnetic field.

4. That field, sweeping past the rotor, induces its own current and compels the rotor to turn either in near lock-step or with a slight slip

A characteristic of motor

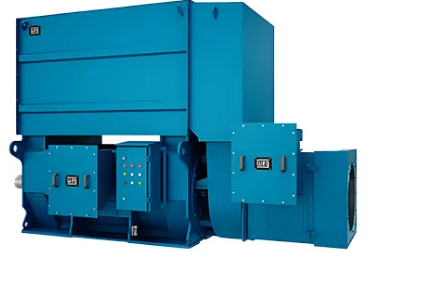

WEGs Master Line of three-phase induction motors is built for the toughest factory floors, delivering reliable power, extended service life, and consistent output even under heavy loads. Covering a power spectrum from 220 kW to 23,500 kW, the line meets the needs of both mid-size workshops and very large plants. Regardless of scorching heat, freezing cold, or the demands of a non-stop production schedule, these motors perform with stamina, durability, and energy-smart design.

Flexible Power and Voltage Option

Master Line motors can be ordered for any voltage up to 13.8 kV and run smoothly on either 50 Hz or 60 Hz supply, an advantage in plants that switch grids or import hardware overseas.

- This broad compatibility suits applications from steel mills to ship propulsion systems, where every detail counts. Units carry efficiency ratings from IE2 to IE5, so managers can meet tighter legislation while trimming energy bills.

- The hallmark of every WEG motor is its MICATHERM insulation package, built through the Vacuum Pressure Impregnation (VPI) technique. Using plant-friendly epoxy, this approach delivers void-free windings with exceptional thermal and dielectric strength.

- The method is well-known for boosting the durability of coil insulation in high-voltage units operating between 380 V and 15,000 V. It also guards against moisture and pollutants, considerably extending the motors working life.

Application Versatility

Modern design software, paired with exacting production techniques, allows these motors to shine in many fields, including:

- Mining

- Oil and gas

- Marine and offshore

- Wastewater treatment

- Cement and steel plants

- Sugar, ethanol, and paper mills

Engineered layouts and top-tier materials position the Master Line as a dependable power choice in varied mechanical and environmental conditions.

Construction & Maintenance Features

Bearings

Inside the casing, premium ball bearings fitted with grease channels and drain points make routine servicing quick and lessen the odds of failure.

Cooling System

Specially shaped fans and a contoured stator promote steady airflow, cut heat loss, and keep temperature stable even during extreme loads.

Insulation Options

Most motors use Class F insulation, yet Class H material is on hand for extreme heat, adding a margin of thermal protection.

Installation & Environmental Precautions

Installation

During fitting, staff must align the motor properly and place it where air can move freely. Misalignment or poor airflow can quickly undermine efficiency and cooling.

Maintenance

Routine checks cannot be skipped. Inspect bearings and watch the lube system. Also, examine windings and the coolant path for any sign of overheating or wear before it becomes serious.

Environment

Match the motors IP grade to the site. In dusty, humid places, choose IP55 or IP65 gear to keep that investment working longer.

Key Components of a Three-Phase Motor

1. Stator Windings

Copper or aluminum coils carry the three-phase current.

2. Roto

Fits in one of two styles

• Squirrel cage rotor (the workhorse)

• Slip ring or wound roto

3. Bearings

Lower friction and keep the shaft aligned.

4. Enclosure Types

• TEFC (Totally Enclosed Fan Cooled) for dirty sites

• ODP (Open Drip Proof) where dust is light

5. Insulation Clas

B, F, or H grades set the motors heat ceiling.

Motor Control Technologie

Keeping a three-phase motor under tight control boosts both performance and energy savings.

Variable-Frequency Drive (VFD)

A VFD tweaks the voltage and frequency, letting the motor spin only as fast as it needs. That makes it the go-to choice for HVAC fans, conveyor belts, and chillers.

Motor Starter

-DOL (Direct-On-Line) Starter

-Star-Delta Starter

-Soft Starter: Eases the hit of inrush current at power-up.

Overload Protection

Thermal relays and circuit breakers guard against overheating and mechanical stress.

Advantages of Using a Three-Phase Motor

Because they run smoother and waste less power, three-phase motors are the backbone of most factories and commercial buildings. Read on for four quick reasons they remain so popular.

High Efficiency (up to IE4)

Many three-phase units rate at IE2, IE3, or even IE4, so they slice power loss compared to single-phase models.

Better Power-to-Weight Ratio

They pack more horsepower into a smaller frame, fitting snugly into tight equipment layouts.

Lower Operating Costs

Less wasted electricity and longer service intervals translate directly into lower monthly bills and repair expenses.

Self-starting

Thanks to the rotating magnetic field supplied by the three-phase grid, these motors start by themselves and skip the extra capacitors or switches single-phase units need.

Reliable and Rugged

Engineered for round-the-clock use, these motors outlast the competition and shrug off tough shop-floor challenges.

Steady Torque Output

They deliver even torque, keeping machines smooth and nearly vibration-free-a must for delicate or precision gear.

Conclusion

The three-phase motor quietly drives modern industry. Whether its a production line, compressor, or pump, this motor offers efficiency, long service life, and trouble-free operation. At VIBRANT we design high-performance solutions for real-world factory demands. Our motors take the roughest conditions in stride while cutting energy costs and delivering dependable service. Ready to lift your operation? Reach out to us today for expert advice and first-rate motors.