Top-rated VFD Air compressors in Russia operate under Variable Frequency Drive design and the capability to ensure that the motor speed automatically changes depending on the demand for air. Such systems are energy-saving and minimize unnecessary wear on the elements, unlike conventional fixed-speed compressors, which are energy-consuming. Air compressors that use inverters and compressors with a variable speed drive are not only energy efficient but also offer a consistent supply of air to the process in industries.

- Intelligent compressor motor control over the right pressure and flow.

- Soft-start compressor technology which minimizes the startup effect.

- Optimization of Load/Unload to align air supply and demand.

- Variable speed compressors with high CFM to guarantee uniform performance.

- Inverter compressors with low noise that are suitable for workshops and factories.

These characteristics make the energy-saving VDF air compressors the best choice of industrial VDF compressors in Russia, especially where these are used in air supply systems of manufacturing plants and heavy industrial use.

Favorability of VFD Air Compressors by Industries

- Energy Conservation and Money Saving

Energy optimization of compressed air systems is one of the largest benefits of the VFD technology. The outdated compressors tend to operate at maximum capacity, an action that wastes energy in times of low demand. The variable speed air compressors mean that the motor dynamically changes its speed, thus saving on energy use and also on the cost of electricity.

The mining, metallurgy, and petrochemical industries in Russia have adopted VFD air compressors with high efficiency levels to reduce operational costs without altering the performance of air pressure.

- Improved Operation and dependability

Modern rotary screw VFD compressors and VFD screw air compressor Russia designs provide high CFM, and controlled accuracy of speed, which ensures that the machinery receives a constant supply of compressed air. It is also further improved by the use of frequency inverter motors and permanent magnet motor compressors (PM motors), which are more reliable, need less maintenance, and extend the equipment life.

- Reduced Noise and Environmental Effect

Industrial compressors that are micro-oil lubricated, low-energy, or have complex rotary screw compressors have less noise and vibration, which reduces the impact and environmental footprint at the workplace. These are energy-efficient compressed air systems that are useful in industries like automotive manufacturing and food processing in Russia.

PM VSD Screw Air Compressor: Accuracy and Cost-Efficiency

The PM VSD Screw Air Compressor is rated among the best VFD air compressors in Russia due to its control and optimum efficiency.

The main benefits of PM VSD Screw Air Compressor:

- Stable and Reliable: Fast control, small overshoot, and good steady-state performance.

- High Efficiency and Energy Saving: VSD also varies the speed of the motor when there is a change in demand and saves energy.

- Soft starter: Soft starter decreases start current to 1.2 time’s rated current, guaranteeing smooth operation.

- No Oil Leakage: There is no leakage, as a high-performance air end was developed in Germany.

- Reduced Noise and Vibration: Wear and maintenance are minimized, and noise and vibration are reduced.

- Reduced Maintenance expenses: Quality components enhance life expectancy and decrease maintenance programs.

- Smart Process: Controller checks 20+ variables to predict maintenance and enhance reliability.

- Micro-Oil Lubrication: Provides high-quality compressed air, which is better than the quality of ordinary output.

In comparison, this PM VSD screw air compressor is best suited to motor and automotive industries and provides a wide range of energy-saving options, low-emission, and high performance in demanding schemes.

Use of VFD Air Compressors in Russia

Air compressors with Variable frequency drive in Russia are generally utilized in a wide range of applications:

- Factories use air compressors in the industry.

- Russian automation of the industry.

- Mining and metallurgy heavy-duty compressor systems.

- Systems of energy management in factories.

- Compressors in automotive workshops.

- Food processing air systems

Such compressors offer high-efficiency air delivery, economized motor action, and cost-saving in the long term in all areas that they serve.

Selecting the Optimal VFD Air Compressor

In finding the best VFD air compressors in Russia, look:

- Energy-Saving Characteristics: Find variable-speed controlled air compressors and low-energy industrial compressors.

- Performance Ratings: Compare CFM and PSI performance rates and level of noise, as well as precision speed control.

- Maintenance and Reliability: Inspection of good-quality components, micro-oil lubrication, and intelligent operation controllers.

- Brand Reputation: It is advisable to use the best manufacturers of VFD air compressors in Russia that have good track records.

- Business Issues: Take into account the VFD air compressor cost in Russia, suppliers, and distributors’ availability.

As an instance, the top-rated VFD Air compressors in Russia incorporate all the features, hence they are among the best-rated equipment in Russian industries.

Benefits of VFD Air Compressors to the Russian Industries

- Less Energy Wasting: The automatic speed control guarantees low usage of electricity.

- Stable Air Pressure: Motor speed regulation compressors offer a stable supply of operations of critical processes.

- Durability: Made using high-strength materials that serve long.

- Minimal Maintenance: High-quality parts reduce maintenance and downtimes.

- Environmentally Friendly: The environment and labor force are favored with low emissions and silent operation.

Russia has seen industries, including petrochemical factories and auto industries, investing in energy-saving VFD compressors to be used in the industries in the country to achieve both economic and environmental objectives.

Purchasing and installation of VFD Air Compressor in Russia

When one buys a VFD air compressor in Russia, then one must:

- Choose a trusted supplier: Vibmac provides trusted suppliers of VFD compressors in Russia.

- Comparison models: Process industrial compressor reviews, technical characteristics, and energy-saving possibilities.

- Check installation requirements: Check that the air systems used in the factories can be connected to the variable frequency drive air compressors.

- Take into account ROI in the long run: Include energy savings, low maintenance, and reliability throughout the lifespan of the compressor.

Conclusion

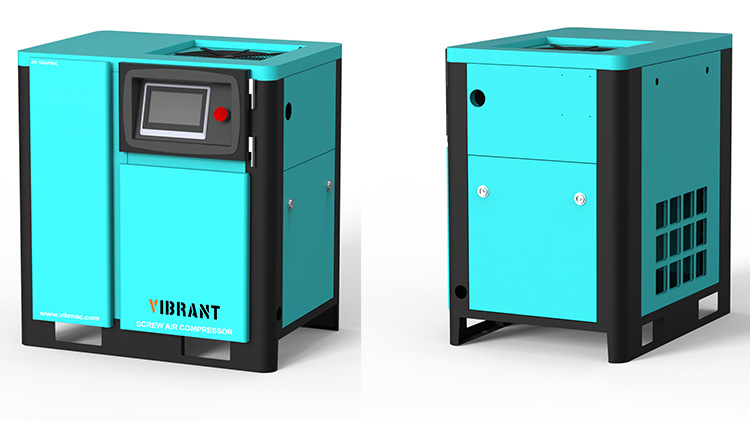

The top-rated VFD Air compressors in Russia are rated top in Russia, but are not merely equipment; instead, they are solutions to modern industrial efficiency. They optimize production and operational cost through the combination of advanced VFD technology, high-CFM output, energy-efficient systems, and consistent performance. As a solution for industrial air compressors in Russia, consider the VIBRANT line today and invest in some compressors that will make your plant work.