A frequency converter air compressor (also known as a frequency converter Russia) is a smart compressor air pump that uses a varying frequency of the electrical power applied to it in order to control its speed. A Variable Frequency Drive Air Compressor in Russia has a motor speed that is adjusted to the air demand, unlike traditional compressors that operate at a constant speed, making sure that no energy is wasted.

This intelligent control lowers start-up spikes, lowers wear and tear on internal parts, and leads to massive energy savings- a characteristic that is particularly important to Russian industries that are 24/7 and high-demand environments.

The Energy-Saving Technology in VFDs: The Power Behind VFD

The main advantage of an air compressor screw frequency drive in Russia is energy efficiency. In a conventional compressor system, the motors operate at a fixed speed even when the air is not needed, and thus, there is wastage of energy and a rise in the cost of operation. Nevertheless, VFD air compressor Russia regulates the motor speed automatically to determine the exact volume of air that the system needs.

This smooth control reduces power wastage, and it also helps in saving up to 35-50 percent of energy, depending on how it is used. It also limits the mechanical stress on the compressor motor and belts, hence increasing the life of the equipment and reducing the cost of maintenance.

Additionally, VFD units are used to regulate the pressure of compressed air, so that the plant can run under the most favorable conditions- an essential requirement in sensitive industries such as automotive assembly, food packaging, and chemical processing.

The introduction of the JX-270AS-WEG: The Excellence of VFD Air Compressor

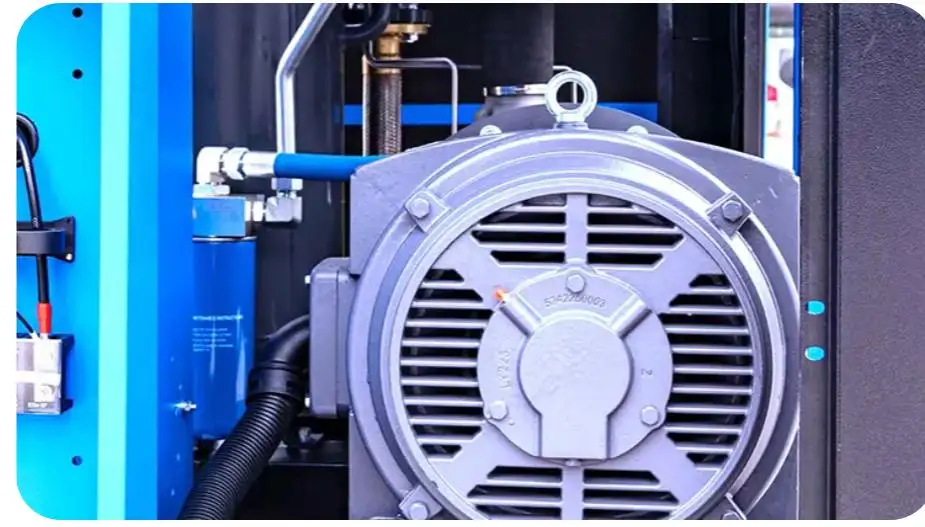

Variable Frequency Drive Air Compressor with WEG Motor is considered to be one of the most impressive examples of innovation in this sphere. This model was designed by Vibrant to suit the requirements of the challenging industrial conditions; it is represented by high efficiency and robust engineering, and high reliability.

The Essence of Energy Efficiency

The Air Compressor VFD Energy Savings JX-270AS-WEG is an appliance that is specifically designed to achieve the best energy management. This compressor uses the VFD technology to control the pushing and pulling rate of air compression as directly affected by the actual demand. This implies that when the air need is low, the compressor will automatically reduce its pace, thus using less electricity, and when the demand for air is high, it will pick up quickly and will not waste any energy.

Such dynamic control enables the business to make substantial savings in expenses, thus making the JX-270AS-WEG not only ecologically friendly but also cost-effective.

Key Product Features

Superior Energy conservation

The Variable Frequency Drive Air Compressor in Russia variant is an energy-efficient one that aims at maximizing each watt used. The VFD system keeps the power utilization and consumption at the same level with the air consumption to provide the maximum performance at the least wastage. Companies will be able to save on their electricity bills as well as reduce the amount of carbon emissions.

High Air Delivery

The JX-270AS-WEG has an impressive airflow rate of up to 32.5 m3 /min (1147.6 CFM) and therefore provides a steady high rate of air flow even in the most challenging conditions. This has seen it be a sure selection in large factories and industrial workshops where continuity is crucial.

Noise Reduction

This frequency drive screw air compressor, the Russian model has a noise level [?]86 dB(A) +-2, unlike conventional compressors. The reduced acoustic footprint ensures that it can be installed indoors and also used in the work environment where low noise is an issue of concern.

Principle Elements and Architectural Planning

Compressor Unit

The compressor unit was designed to perform and last long with a minimum number of vibrations and heat generation. It is designed to provide uniform air pressure and high-functioning dependability of applications that require long-term usage.

Variable Frequency Drive (VFD)

The key component of the system is the Variable Frequency Drive that regulates the input frequency and voltage of the motor. This not only increases the precision of the operation but also reduces mechanical stress on bearings and shafts, which further increases the lifespan of components.

Cooling System

The cooling system is built into the compressor to ensure that the compressor works at optimum temperatures continuously during a long period of time. It also eliminates excessive heating and improves the efficiency of the output of air, which makes the system reliable even in cases of high workloads.

The revolution of VFD Air Compressors in the performance of the industry

Saving energy and sustainability

The savings in the energy consumption of VFD air compressors in Russia provide quantifiable incentives to the total energy consumption by adjusting the motor speed to correspond to the current demand. This aspect underpins the emerging trend of sustainable industrial development in Russia and assists industries in being in line with the global standards in energy efficiency.

Better Quality of Air and Pressure Stability

The system ensures that there are no changes in pressure over time because air is under constant pressure, which will lead to interruptions in the manufacturing processes. Variable frequency drive air compressor Russia is the one that helps you to be sure that all your tools, machines, and pneumatic systems will have clean and stable air all the time.

Extended Equipment Life

Traditional compressors usually undergo repeated start-stop cycles. The VFD air compressor in Russia reduces these mechanical stresses as the acceleration and deceleration process of the motor is smooth, hence increasing the working life of the motor and its associated components.

RFID Applications of VFD Air Compressors in Russia

The wide applicability and effectiveness of the frequency converter to air compressors in Russia render it suitable for a wide variety of applications, which include:

Manufacturing Stations - operating pneumatic tools and assembly lines.

Oil and Gas Facilities - reliable supply of air in adverse conditions.

Automotive Industry- assists in precision painting, polishing, and assembly activities.

Food and Beverage Processing - the use of contamination-free compressed air.

Chemical and Pharmaceutical Plants - in favor of accurate dosing and packaging systems.

The energy-efficient air compressor with VFD Russia is fast gaining acceptance by industries all over Russia because of its capability to deliver both high-quality performance and green energy consumption.

Why Choose Vibrant?

Vibrant is a reputable company in terms of providing high-performance industrial air compressors to various markets around the world, and Russia is not an exception. The company is oriented towards excellence in engineering and energy efficiency, and customer satisfaction.

Not only are the solutions offered by Vibrant made to offer compressed air, but the solutions also offer optimized energy efficiency that changes the economics of operations. They incorporate smart control systems and VFD mechanisms to integrate intelligence that will guarantee performance and reliability over the years through constant R&D.

Final Thoughts

In the current world of intense industrial competition, success is characterized by efficiency, reliability, and sustainability. It has the ability to empower business organizations to deliver air most efficiently with high-intelligence VFD technology, adaptive motor control, and powerful design, which helps save a lot of energy.

The JX-270AS-WEG by Vibrant is a new standard of excellence in air compressor engineering- not only compressed air, but smart performance, economics, and durability. Regardless of whether you are renovating an old system or coming up with a new facility, an investment in one of the frequency drive screw air compressors Russia will be a move that will see to it that your operations are efficient, sustainable, and future-ready.