Introduction

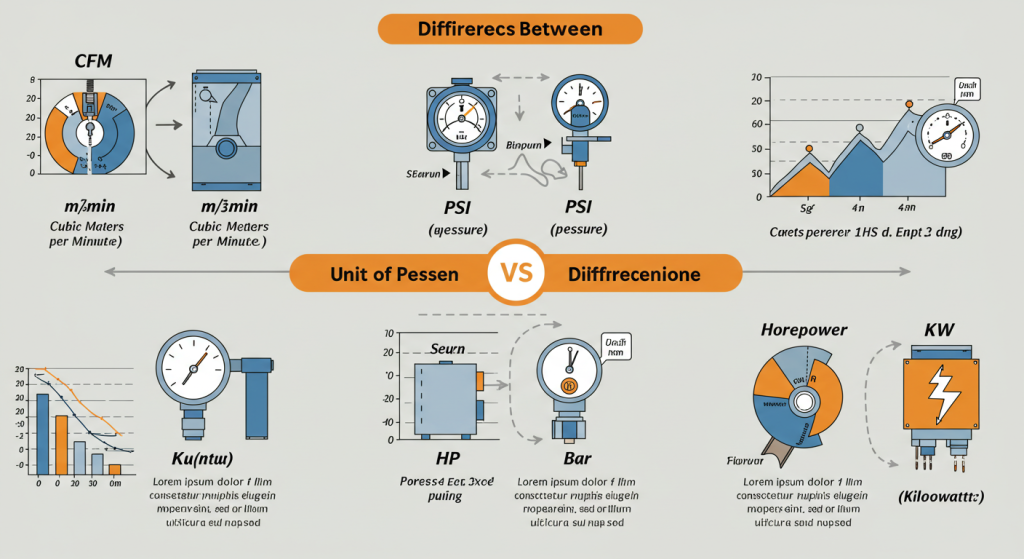

Engineering disciplines-from HVAC and air-compression systems to automotive engineering and shop-floor manufacturing, on precise measurement units. Whether technicians are sizing ducts, rating compressors, or tuning electric motors, they must understand the nuances between terms such as CFM, m3/min, PSI, Bar, HP, and kW.

- These designations come from two overarching measurement systems, the Imperial and the Metric. So, how do users compare, convert, and apply them in real-world scenarios? This article reviews CFM, m3/min, PSI, Bar, HP, and kW in plain English, clarifying their relationships while maintaining technical detail.

- Before diving into numbers, it is natural to wonder why the same physical quantity can bear so many labels. The answer lies in history, local practice, and the specific needs that arose within each trade.

- Metric Units and SI Units: Most nations have adopted the metric system because its tidy 10-based steps make calculations easy. The International System of Units (SI) builds on that foundation, threading every measurement into a single, coherent structure.

Demystifying Flow Rate: CFM vs. m³/min

What are the differences between cfm, m3/min, psi, bar, hp, kw? Flow rate generally describes the volume of air, water, or other substance that passes a fixed point within a certain time. In any fluid-system discussion, that volume is what engineers and technicians care about.

CFM: Cubic Feet per Minute, Imperial Measure of Airflow

Cubic Feet per Minute (CFM) remains the workhorse unit where Imperial practice lingers. It shows how many cubic feet of gas usually flow past a chosen location every sixty seconds. Think of it as the every-minute lung capacity of a duct or fan.

- Technical Breakdown: One CFM equals the space of a one-foot cube filled with air during one minute.

- Common Applications: CFM figures show up wherever designers need to tune, monitor, or guarantee controlled airflow.

- HVAC units- air conditioners, furnaces, and exhaust fans are rated by cubic feet per minute (CFM) so that air circulation matches heating or cooling loads and supports indoor air quality. Higher CFM typically allows a space to reach the desired temperature more quickly and keeps odors and humidity from lingering.

- For air compressors, the CFM rating indicates the volume of pressurized air available over time, grounding the idea in a familiar workshop context. That flow volume tells users which pneumatic tools will operate efficiently. A paint spray gun may ask for 10 CFM at 90 pounds per square inch, whereas a 3/8-inch impact wrench often needs only 5 CFM at the same pressure.

- In practice, an HVAC system that cannot produce adequate CFM leaves living areas sticky and unevenly warm, while an underpowered compressor turns nail guns, ratchets, and sanders sluggish or, occasionally, motionless.

- The metric counterpart for CFM is cubic meters per minute, abbreviated CMM for cubic meters per minute. It describes how much gas or liquid crosses a given cross-sectional area in one minute.

- To put it simply, one cubic meter per minute means one full meter-cube of air crosses a set point every sixty seconds. Picture a box where each edge measures exactly one meter. Since a meter is about 3.28 feet, that volume is much larger than most people realize.

Bar: The Metric Unit of Pressure Near-Sea-Level Anchor

The bar sits just below average sea-level atmospheric pressure and remains a practical everyday reference. Even though it falls outside the formal SI system, most engineers still favor it because its scale feels familiar.

- Technical Breakdown: One bar is, to the last decimal, 100,000 Pascal or 100 kPa.28 For comparison, standard sea-level air presses down with roughly 1.01325 bar. 29

- Common Applications: The bar dominates pressure reporting in much of Europe and Asia, influencing both car work and factory assembly.

- Industrial Process Control: Chemical plants, oil and gas stations, and even municipal water systems often track internal pressures in bars.

- Diving Equipment: Scuba cylinders and regulators also use the bar scale, giving divers a clear picture of the remaining gas volume.

- Hydraulic & Pneumatic Systems: On assembly lines and in CNC machines, technicians express hydraulic and compressed-air pressures in the same unit.

- Why it Matters: Since the bar sits so close to everyday engineering pressures, it feels more natural than the smaller Pascal, yet it meets scientific standards.

Pressure: PSI (Pounds Per Square Inch)

Measures pressure and, as such, it remains the conventional choice in the United States and some industrial sectors. Applied in tires, hydraulic presses, air tools, and all else that must work under a set load.

- Unleashing Power: HP vs. kW

Power tells you how fast work gets done, or how quickly energy moves from point A to point B. Whether you hear a roaring combustion engine or notice the quiet whir of an electric motor, power is the unseen force making that motion possible. In this section, we line up two familiar measures (HP) and kilowatts (kW)-so engineers can see at a glance how they compare.

- HP: Horsepower Legacy of Power

Horsepower, abbreviated HP, is an Imperial term first popularized by British engineer James Watt. In the late 1700s, Watt measured the pulling strength of a draft horse and set that benchmark beside the output of his steam engines so clients could picture what they were buying. One horsepower works out to roughly 746 watts, giving the unit practical meaning in everyday settings.

How Quickly Can a System Perform?

Laboratories and utilities around the world, instead, work with the kilowatt (kW), the standard International System unit. Research shows that one kilowatt equals 1,000 watts and describes the steady flow of power that lights roughly ten compact fluorescent bulbs, runs a basic electric oven, or raises a large pickup truck one meter in a single second. Because kilowatts measure the rate at which energy is delivered rather than the total supplied, the term explains how quickly a system can perform meaningful work.

- Technical Breakdown: A single kilowatt equals 1,000 watts. Formally, a watt (W) stands for one joule per second (J/s), so the kilowatt links power to energy flowing over time.

- Common Applications: Engineers and technicians routinely switch to kilowatts when discussing larger electrical loads.

- Electrical Appliances: From kitchen toaster ovens to assembly-line robots, almost every plug-in device labels its demand in watts or kilowatts.

- Electric Vehicles (EVs): Both EV motors and their onboard chargers almost always report power output in kilowatts.

- Power Plants: Commercial generating units express their output as megawatts (MW), which means thousands of kilowatts.

Embracing the Future of Measurement

What are the differences between cfm, m3/min, psi, bar, hp, kw? As markets widen and technology speeds ahead, the ability to switch seamlessly between basic units is more crucial than ever. Even where Imperial measures persist, the straightforward, worldwide charm of SI and metric units quietly nudges most nations toward a shared standard.

Conclusion

Once you see how CFM, m³/min, PSI, Bar, HP, and kW connect, those figures stop feeling like insider code and start sounding like practical points you can use. Flow, pressure, and power then outline their place in your setup, and you scan datasheets with the calm assurance of someone who knows the field. At VIBRANT, we understand that factory equipment, maintenance schedules, and fault checks hinge on an exact dance of different measures. Because we work every day with machines specced to contrasting systems, we guide clients in lining up and harmonizing those technical quirks.