Overview of Instrument Air

What is instrument air? Instrument air is the refined breath of a plant, the compressed air that keeps every industrial machine humming without a hitch. Before it ever reaches a valve or circuit, the air is cleaned, dried, and stripped of oil, so each puff can be trusted to power sensors, actuators, and safety loops. Think of it as the premium air reserved for tasks where accuracy and dependability matter most.

Core Definition & Characteristics

Instrument air is the same thing as clean dry air (CDA)-compressed air that has been scrubbed free of moisture, oil, and particulates. Many engineers simply call it treated compressed air or oil-free air. The goal is pure perfection, with tight limits on the dew point, grit, and oil content-usually spelled out in parts per million (PPM). Key quality metrics:

- Dew point: Typically held at -40 °C, and often pushed to -70 °C.

- Particulate content: Sized, counted, and classified per ISO 8573.

- Oil content: Kept near zero PPM to spare every valve and sensor inside.

Why Use Instrument Air?

- Instrument control and actuator operation

Pneumatic valves and cylinders want nothing but clean, stable air. Even a hint of moisture or grit can clog ports, rob speed, or freeze pipes.

- Instrumentation power

Small instruments- tiny transmitters, sensors, and gauges- rely on dry air to shift parts or signal controllers. Give them spotless air, and the readings stay true while the hardware lasts longer.

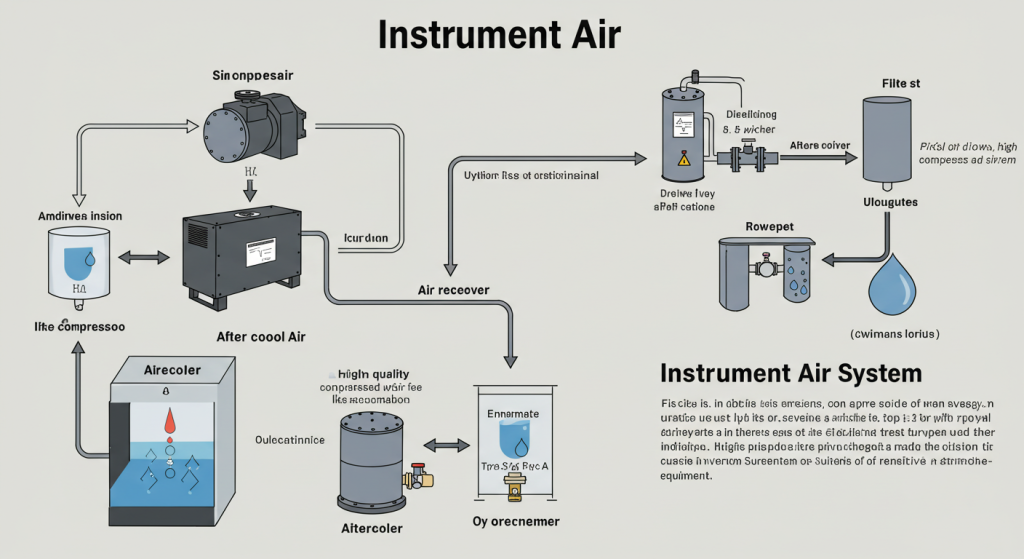

Steps: An Instrument-Air Package

1. Air compressor- often oil-free, either small rotary or compact reciprocating.

2. Air dryer- removes moisture; options are refrigerant dryer (dew point near 3 °C) or desiccant dryer (heatless, heated, or blower purge, down to about -70 °C).

3. Air filtration-pre-filters, coalescing stages, and fine strainers sized for the job.

4. Air-receiver buffer tank catches pressure spikes and stops the water hammer.

5. FRL unit-filter-regulator-no-lubricator-that cleans, controls pressure, and sets flow.

6. Piping network-thick stainless tubing or tested copper that shrugs off rust and leaks.

7. Dew-point monitor pings staff as soon as moisture climbs past the safe mark.

Technical Specs & Standards

- ISO 8573-1

ISO 8573-1 is the yardstick for compressed-air quality. It splits purity into three big worries: solid particles, moisture (dew point), and oil. Instrument-air stations usually shoot for:

- Solid particles: Class 1 or 2-nearly no dust you can catch with the eye.

- Oil content: Class 1-keeps below 0.01 mg/m so circuits stay clear.

- Dew point: Class 4 or better-at least -40 C to ward off freeze-up and rust.

- ISA 7.0.01

ISA 7.0.01 takes over where ISO 8573 stops, drilling down on instrument-air loops. It upholds the same purity targets yet adds rules on pipe runs, gear layout, and upkeep. Fields such as oil and gas or pharma treat it as gospel since tiny slips can spark huge losses.

- Dew-Point Requirements

A low dew point means the air feels very dry, and that fact matters even more when pipes sit outdoors or chill in cold rooms. On outdoor rigs, -40 C is the usual target to keep moisture from freezing and blocking flow, while reading around -20 C often keeps indoor gear happy.

- Particulate & Oil

Even the tiniest specks of dust or drops of stray oil can slow a valve or sensor. Traces of oil may ruin sensors altogether and stick valves shut. Because of these threats, multi-stage filtration is not merely smart; it is the first shield on the front line.

Instrument Air in Different Industries

- Oil & gas, chemical plants

Air powers control valves and trigger emergency shutdowns, so specs must call for explosion-proof gear built for heavy cycling.

- Power generation

Clean, dry air feeds turbines and steadies boiler controls; tight dew-point limits stop ice from forming at altitude.

- Pharma & medical

Every cubic meter must meet strict sanitary standards, and labs even use the air for instrument and sensor calibration.

- Food & beverage

- Air contacts packaging and cleaning lines, so quality has to be top-grade.

- General process industry

- Most plants lean on dried, filtered air for countless crucial tasks.

What is Designing an Instrument Air System?

- Compressor selection

Pick between oil-free or oil-lubricated, with rotary-screw or reciprocating oil-free units being the most common choice.

- Dryer Selection

If dew points stay steady, choose a refrigerated dryer; for the roughest spec, go straight to a desiccant.

- Filtration & distribution

Air should first meet a pre-filter, then the dryer, next a coalescer, a particulate, and finally a final FRL. Calibrated regulators after that balance pressure with the flow each piece of gear expects.

- Sizing & redundancy

Set the receivers large enough to hold thirty to sixty seconds of peak demand, and twin units let crews pull one offline.

- Monitoring & Alarm

Dew-point sensors, pressure gauges, and filter-differential readouts all chat, and you receive an instant auto-alert.

Why is Vibrant the Best Air-Compressor Supplier?

What is instrument air? At Vibrant, we do more than drop off a compressor; we lay out a design that feels as if it were sketched on your shop floor. Our engineers love puzzles, so they mix hard-won know-how with the spark needed to untangle your toughest air-demand headaches.

- Certified Quality

We follow the world's strictest rule books, so every machine earns its ISO, UL, CE, EMC, TUV, or SAA badge. With Vibrant, sturdy, quiet, safe work is never left to chance; we test each unit before it leaves the dock.

- Fast Support

Need help at three in the morning? No sweat. Our twenty-four-hour team picks up every call, sends a tech your way, or fixes the hiccup online, keeping your downtime to a whisper.

- Custom-Built Solutions

The packaging plant next door works differently from your shop, so every compressor we deliver starts with a clean spec sheet. We listen, measure, model, and then build a unit that cools, runs, and exhales exactly the way your line needs.

- Competitive Pricing

Lean methods and smart stock keep our costs low, and we never cut corners, so you still get rugged parts and full factory backup. That way, the price tag stays fair without clipping performance.

Conclusion

What is instrument air? Instrument air is clean, dry, oil-free air that keeps control and safety systems healthy. You’ll find it on oil rigs, in pharma plants, and at power stations. Pair robust compressors with dryers, filters, receivers, and steady monitoring, and you secure reliable actuation while shielding the entire system. If you have any queries, contact VIBRANT.