Overview

What is the compressed air tank and how to choose? An air receiver tank, sometimes just called a compressed-air tank, is a sturdy metal drum that keeps a supply of pressurized air ready for work. By holding that air between the compressor and the tools, the tank smooths out pressure bumps, feeds steady airflow when demand spikes, and cuts down on how often the compressor has to start and stop.

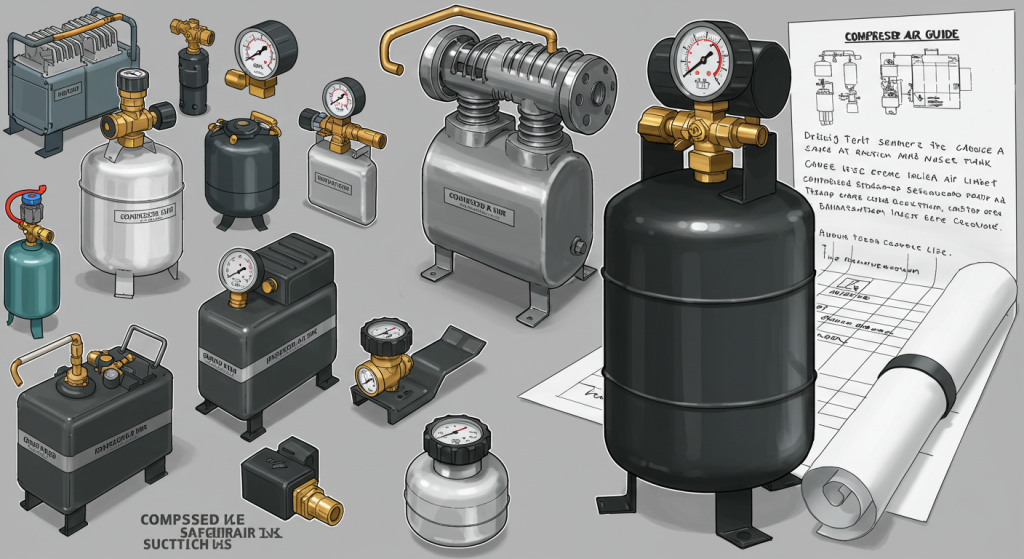

These tanks can stand tall (vertical) or flat (horizontal), and they are usually built from tough steel or lightweight aluminum so they can safely hold air at high pressure. To keep everything safe and dry, most tanks come loaded with friendly extras: a pressure gauge to show how much air is inside, relief valves that open if things get too hot, drain taps for the water that sneaks in with the air, and sometimes moisture filters that catch the last bits of humidity.

Functions and Benefits of an Air Tank

So why is this hunk of metal so important? Its job list goes far beyond simple holding and the payoffs, ranging from boosted efficiency to improved safety to longer equipment life. Every compressed-air system runs happily.

Air Reservoir Basic: The tank's main job is to store air, giving you a quick pool of pressurized air so the compressor doesn't have to start and stop all the time. That constant on-off dance can wear out the motor long before its time.

Pressure Stabilization: Turning on a faucet and getting a weak spurt, then nothing, then another spurt. Without the reservoir, air tools would feel those same bumps in pressure. The tank smooths the flow, feeding your drills, sprayers, and rivet guns with steady air, which keeps them working better and lasting longer.

Moisture Removal Wet Tanks: When the air gets squeezed, hidden water vapor cools and drops into liquid. A wet tank plumbed right after the compressor gives that water a place to settle. That way, moisture doesn’t creep into your favorite tools and start rusting or swelling. And when it is time to clear the tank, a simple drain valve at the bottom makes the chore quick and clean.

Pulsation Dampening: Every time a crank moves in a reciprocating air compressor, it sends a quick thump through the air. An attached tank catches those bumps, smoothing the stream before it hits your tools, airbrush, or engine. For delicate jobs, that steady flow can make the difference between clean lines and unexpected hiccups.

Energy Efficiency (Reduced Compressor Cycling): Tired of your wallet flinching every time the compressor kicks on? A storage tank helps by giving the system a cushion; the pump fills the tank, shuts down, and then sleeps until demand spikes again. Far fewer stop-go battles save power and keep the motor from burning out.

How to Select the Perfect Compressed Air Tank

Picking the right tank isn’t simply grabbing what looks big or shiny. You need to measure your projects, review the tools' duty cycle, and keep a little technical know-how at hand. With the right checklist, choosing the correct model goes from guesswork to a smart, targeted choice.

Understanding Air Tank Sizing: The Heart of the Matter

The first rule of tank shopping is capacity: how much air do you use? It is not about hoarding the biggest barrel in the store; it is about matching the size of the tank to your needs and the compressor output.

Air Demand (CFM): CFM simply shows how much air the tools and gear pull in a minute. Add up the numbers for every item you plan to run at the same time. That sum is the firm baseline you can’t ignore.

Duty Cycle: Next, ask how often and how long those air-powered gadgets will be busy.

Intermittent Use: short bursts, like nailing or sanding, followed by quiet pauses.

Continuous Use: nonstop work, such as spraying or polishing, where airflow never really stops.

Compressor CFM Output: This figure tells how fast the compressor fills the pipes and tank. Your tank needs to match that speed and the demand you wrote down earlier.

Pressure Rating (PSI): Topping Safety

A tank's pressure rating is the first safety line. It tells you the highest pressure the vessel can handle, usually shown in pounds per square inch (PSI). Always check that the number is higher than the compressor's max output.

ASME Certified Air Tanks show safety you can trust. If your project is heavy-duty, search for a tank that carries the American Society of Mechanical Engineers stamp. ASME rules for design, welding, and testing are tough, and that logo means the tank passed. With it, you gain peace of mind and sometimes meet legal rules.

Related Equipment and System Integration

An air receiver rarely works alone; it sits in a network of parts. Knowing those neighbors helps you tune the whole system.

Air Compressor System: This unit generates the pressurized air. The tank's volume, fittings, and pressure match your compressor output, so the two speak the same language.

Air dryer: If you paint furniture, run delicate gear, or use air tools that hate moisture, a dryer is a must. It pulls water vapor out of the compressed air right after the pump and usually before the storage tank, guarding against rust, corrosion, and messy spills.

Air filter: This handy device catches dust, tiny metal chips, and oil mist so only clean air reaches your tools and jobs.

Pressure relief valve: A lifesaving gadget that opens on its own when tank pressure climbs past the safe line. Never run a tank that doesn’t have a working relief valve.

Pressure gauge: A simple dial or digital readout shows what the pressure inside the tank really is, so you can keep an eye on things.

Compressor controls: These brains decide when the compressor kicks on and off, usually based on the tank's pressure. Tweak them well and you can cut electricity bills.

Air tools: Whether it’s an impact wrench or a paint sprayer, your tools need steady CFM and PSI to work their best, so your tank has to deliver.

Compressed Air Tanks and Factory Efficiency

What is the compressed air tank and how to choose? In big plants, picking the right air tank gets serious because it directly affects the plant's compressed-air setup and its bottom line.

Energy Savings with Air Tanks: When the tank is sized right, the compressor kicks on and off less often, cutting electric bills and easing daily costs.

Air System Efficiency: A good tank keeps air pressure steady, so the compressor works more easily and the entire system runs smoothly.

Condensate Management: Besides the manual drain, many factories add auto drains and oil-water separators to handle all the moisture, guarding machines, and the environment.

Conclusion

In order to support the Equipment Company, VIBRANT works with clients to provide and sell the best and most up-to-date air compressor products. Discover our wide selection of products, which are built on technology for environmental preservation, energy conservation, and high efficiency and stability.